Enhancing Packaging Efficiency: A Technical Look at the FHOPE-R100 Rotary Arm Pallet Wrapper

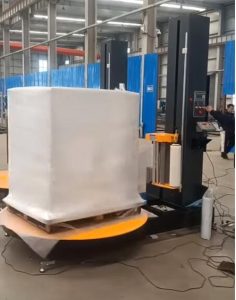

The FHOPE-R100 rotary arm pallet wrapper represents a significant step forward in automated end-of-line packaging solutions. Designed specifically for high-throughput environments and applications involving unstable or heavy loads, this machine optimizes the stretch wrapping process, ensuring load stability, product protection, and operational efficiency. Its core advantage lies in the rotary arm design, which allows the pallet load to remain stationary while the film delivery system revolves around it—ideal for loads susceptible to shifting during rotation on traditional turntable wrappers.

1. Design Philosophy and Structural Integrity

The FHOPE-R100 is engineered for reliability and longevity in demanding industrial settings. Key design considerations include:

- Stationary Load Wrapping: The fundamental principle of the rotary arm minimizes the risk of product damage or displacement during wrapping, crucial for industries handling tall, light, or irregularly shaped pallets.

- Heavy-Duty Construction: Built upon a robust steel frame, the machine ensures stability and vibration damping during high-speed arm rotation. Components are selected for durability, minimizing downtime and maintenance requirements.

- Precision Engineering: The rotary arm mechanism incorporates high-precision bearings and drive systems to guarantee smooth, consistent movement and uniform film application throughout the wrapping cycle.

big pallet wrap 2. Core Components and Advanced Functionality

The FHOPE-R100 integrates several key technologies to deliver superior performance:

- Rotary Arm Drive: Typically utilizing a variable frequency drive (VFD) controlled motor, the arm speed can be precisely adjusted (up to 15 RPM in standard configurations) to match specific load requirements and desired throughput.

- Powered Film Pre-Stretch System: This critical component significantly reduces film consumption (often achieving pre-stretch ratios of 250% or more) while enhancing load containment force. By stretching the film before application, it optimizes material usage and ensures a tighter, more secure wrap.

- Automatic Film Cut and Clamp/Wipe System: Upon cycle completion, the machine automatically cuts the stretch film and secures the tail to the pallet (often via a clamping and wiping mechanism). This eliminates manual intervention, accelerates cycle times, and enhances operator safety.

- PLC Control with HMI: A Programmable Logic Controller (PLC) serves as the machine's brain, managing all operational sequences. Paired with a user-friendly Human-Machine Interface (HMI) touchscreen, operators can easily set parameters, select pre-programmed wrap recipes, monitor machine status, and perform diagnostics.

- Integrated Safety Measures: Safety is paramount. The FHOPE-R100 typically includes safety fencing, access doors with interlocks, emergency stop buttons, and potentially light curtains to protect personnel during operation, complying with relevant safety standards.

3. FHOPE-R100 Technical Specifications Overview

The following parameters provide a general overview. Please note that these specifications may not perfectly match the unit depicted in the video. For precise configurations tailored to your needs, direct consultation is recommended.

- Model: FHOPE-R100

- Type: Automatic Rotary Arm Stretch Wrapper

- Year of Manufacture: 2023 (representative; varies by unit)

- Condition: New

- Maximum Pallet Size (L x W x H): 1400mm x 1400mm x 2200mm

- Maximum Load Capacity: Up to 2000kg

- Wrapping Efficiency: Up to 30 pallets per hour (dependent on load height and wrap pattern)

- Rotary Arm Speed: Adjustable, up to 15 RPM

- Film Delivery System: Powered pre-stretch carriage

- Film Specifications:

- Type: LLDPE Stretch Film

- Width: 500mm

- Thickness: 17-35 microns

- Control System: PLC with Touchscreen Interface

- Key Feature: Automatic Film Cut & Clamp/Wipe System

- Power Requirements: Typically 380V, 50Hz, 3-Phase (confirm specific needs)

- Approx. Machine Dimensions (L x W x H): 4000mm x 3000mm x 3000mm

- Safety Features: Emergency stop buttons, safety fencing (standard configuration)

- Warranty: Typically 24 months (confirm terms)

4. Operational Insights and User Experience

From an operational standpoint, the FHOPE-R100 is designed for ease of use and integration:

- Intuitive Operation: The HMI allows for straightforward setup of parameters like top/bottom wraps, arm speed, film tension, and pre-stretch levels. Multiple wrap programs can often be stored and recalled for different product types.

- Maintenance Accessibility: Thoughtful design usually allows for reasonable access to key components like the film carriage, motors, and control panel for routine maintenance and servicing.

- Integration Potential: The machine can be seamlessly integrated into automated production or packaging lines, often interfacing with upstream and downstream conveyor systems, palletizers, or AGVs.

- Real-World Benefits: Users typically report significant reductions in film costs due to the pre-stretch system, improved load integrity leading to less transit damage, and increased overall packaging throughput compared to manual or semi-automatic methods.

pallet stretch wrapping machine with weighing scale 5. Key Applications Across Industries

The versatility of the FHOPE-R100 makes it suitable for a wide range of applications:

- 5.1 High-Volume Logistics & Distribution: Essential for distribution centers requiring rapid pallet processing. The automation minimizes bottlenecks and labor dependency in securing outbound shipments.

- 5.2 Manufacturing Environments: Protects finished goods post-production, from consumer packaged goods (CPG) and electronics to building materials and automotive parts. Handles varying load profiles effectively.

- 5.3 Securing Unstable or Heavy Loads: Its primary advantage shines here, safely wrapping products prone to toppling or shifting on turntable systems, such as stacked bags, empty containers, or very tall pallets.

- 5.4 Industries Benefiting: Common sectors include Food & Beverage, Pharmaceuticals, Chemicals, Paper & Print, and Building Supplies, where load stability and protection are critical.

In conclusion, the FHOPE-R100 rotary arm pallet wrapper offers a robust and efficient solution for automating stretch wrapping processes. Its design addresses the challenges of wrapping unstable loads while delivering high throughput, material savings through powered pre-stretch, and enhanced operational safety via its automated features. For facilities looking to upgrade their end-of-line packaging capabilities, the R100 presents a compelling option for boosting efficiency and ensuring product integrity during storage and transit.