1. Introduction: Enhancing Cable Packaging Efficiency

In today's demanding manufacturing environment, efficient and reliable packaging is paramount. This automatic cable coil wrapping machine represents a significant step forward for businesses handling cable and wire products. Designed to streamline operations, this unit automates the coiling and wrapping process, directly addressing common bottlenecks found in manual or semi-automatic packaging lines. Whether you're a cable manufacturer or a distribution center, integrating such automation can lead to substantial improvements in throughput, consistency, and overall operational cost-effectiveness. From personal experience integrating similar systems, the transition from manual wrapping to an automated solution drastically reduces packaging time per coil and minimizes material waste, offering a rapid return on investment.

2. Core Technical Specifications

Understanding the machine's capabilities starts with its specifications. These parameters define its operational range and physical footprint:

- Compatible Cable Diameter: 2.5mm to 25mm (approx. 0.1" to 1.0") - Accommodates a broad spectrum of wire and cable types.

- Coil Dimensions:

- Outer Diameter: 300mm to 700mm (approx. 11.8" to 27.5")

- Inner Diameter: 150mm to 250mm (approx. 5.9" to 9.8")

- Wrapping Material Compatibility: PVC film, PE film, Stretch Wrap - Provides flexibility based on protection requirements and cost.

- Power Requirements: 380V, 50Hz, 3 Phase (Confirm specific voltage/frequency needs for your region)

- Machine Dimensions (L x W x H): 1600mm x 1400mm x 1500mm (approx. 63" x 55" x 59")

- Machine Weight: Approximately 800kg (approx. 1760 lbs)

3. Advanced Features and Operational Insights

This cable coil wrapping machine incorporates several features designed for performance, versatility, and operator ease-of-use.

3.1. High Throughput Capability

- Capacity: Capable of processing up to 80 coils per hour (depending on coil size and wrap settings).

- Impact: This level of automation significantly boosts packaging output compared to manual methods, allowing reallocation of labor to more value-added tasks. In practice, consistent cycle times remove variability and improve downstream planning.

3.2. Versatile Cable and Coil Handling

- Range: The ability to handle cables from 2.5mm up to 25mm in diameter, along with adjustable coil OD/ID settings, means this single machine can cater to a diverse product inventory.

- Application: Suitable for power cables, communication wires, control cables, and more, minimizing the need for multiple specialized machines. My experience suggests verifying tension settings for very small vs. very large diameter cables ensures optimal wrap quality across the range.

3.3. Flexible Wrapping Material Options

- Compatibility: Works effectively with standard packaging films like PVC, PE, and stretch wrap.

- Benefit: Allows selection of the most cost-effective or functionally appropriate material. Stretch wrap, for instance, provides excellent coil containment, while PE or PVC films can offer different levels of abrasion or moisture resistance. Material changeovers are typically straightforward.

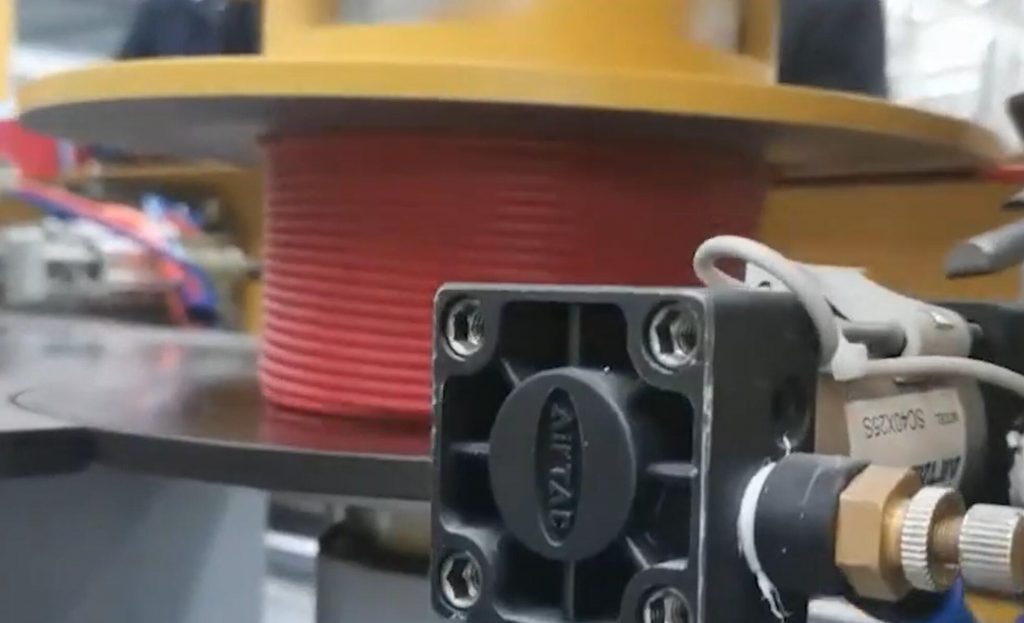

3.4. Precision Control System

- Technology: Utilizes a Programmable Logic Controller (PLC) paired with Inverter drives.

- Functionality: This ensures precise, repeatable control over the wrapping process, including wrap tension, overlap percentage, and cycle initiation/completion. Operators can easily adjust parameters via an interface (HMI often included), simplifying setup for different product runs. This level of control is crucial for achieving consistent package quality.

3.5. Operator-Focused Low Noise Design

- Noise Level: Engineered to operate below 75 dB.

- Workplace Impact: Contributes to a more comfortable and less fatiguing working environment, potentially aiding compliance with workplace noise regulations and improving operator concentration.

3.6. Comprehensive Safety Integration

- Features: Includes guarding around moving parts, accessible emergency stop buttons, and often a main shield cover.

- Importance: These elements are critical for protecting operators during machine operation and maintenance, adhering to essential industrial safety standards. Proper training remains vital, but integrated safety features provide the first line of defense.

4. Operational Advantages for Fabricators

Investing in an automatic cable coil wrapping machine translates into tangible benefits:

- Increased Productivity & Reduced Labor Costs: Automation directly replaces manual wrapping labor, significantly increasing coils processed per shift and lowering per-unit packaging costs.

- Consistent, Professional Packaging: Ensures every coil is wrapped uniformly, enhancing product presentation and protecting cables effectively during transit and storage. This consistency reflects positively on brand quality.

- Adaptability to Production Demands: The machine's versatility handles diverse cable/coil sizes and wrap materials, meeting varied customer requirements without significant downtime for changeovers.

- Simplified Operation: Modern PLC controls and intuitive interfaces reduce the training time required for operators and allow for quick adjustments between different jobs.

- Improved Workplace Ergonomics: Automating the repetitive motions of manual wrapping reduces risks of musculoskeletal strain for employees. The low noise level further enhances the work environment.

- Long-Term Reliability: Built for industrial use, these machines offer durability and consistent performance, ensuring a reliable packaging process day after day. This translates to better ROI and less maintenance downtime compared to less robust solutions.

5. Warranty and Support Assurance

Confidence in equipment performance is key:

- 18-Month Warranty: Provides comprehensive coverage against defects in materials and workmanship, offering significant peace of mind.

- 30-Day Money-Back Guarantee: Demonstrates strong confidence in the machine's capabilities and suitability for purpose.

6. Dedicated Technical Support

Effective integration and ongoing operation are supported by:

- Expert Assistance: Access to a knowledgeable technical team for installation guidance, operator training, and troubleshooting support.

- Maintenance Partnership: Ensuring you maximize the machine's lifespan and operational efficiency through recommended maintenance practices and readily available support.