Vertical Wrapping Machine for Large Bearing and Flange Packaging

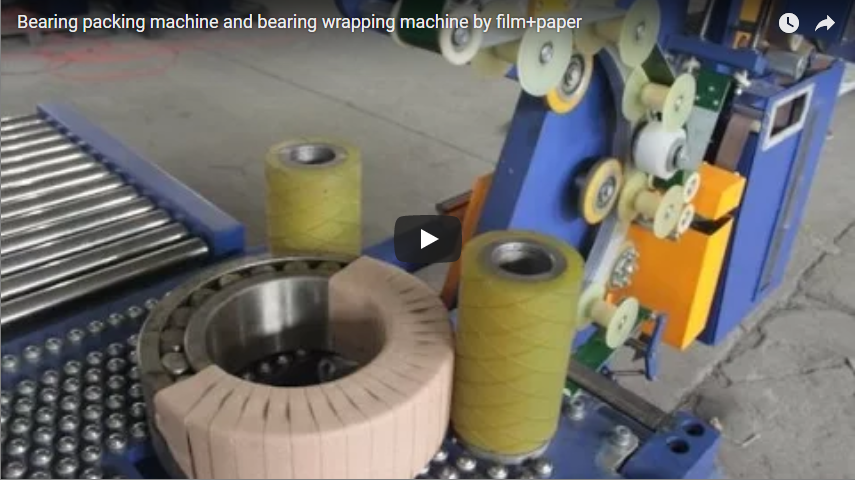

Packaging large, heavy industrial components like bearings and flanges presents unique challenges. These items often require robust protection against corrosion, dust, and physical damage during storage and transit. The video above showcases a vertical wrapping machine specifically engineered to address these needs for oversized, ring-shaped products.

1. The Challenge: Protecting Large, Heavy Components

Standard packaging methods can be inadequate for bearings and flanges with significant diameters and weights. Key concerns include:

- Corrosion: Exposed metal surfaces are highly susceptible to rust and environmental degradation.

- Contamination: Dust and debris can compromise bearing performance.

- Handling Damage: The sheer size and weight make manual wrapping difficult, inefficient, and potentially unsafe.

- Stability: Ensuring the component remains stable during the packaging process is crucial.

2. The Solution: Vertical Axis Wrapping

This specialized machine utilizes a vertical wrapping approach. Here’s a breakdown of the typical operational process:

- Loading: The large bearing or flange is positioned upright onto a set of heavy-duty, powered support rollers integrated into the machine's base.

- Rotation: The support rollers gently rotate the component around its vertical axis at a controlled speed.

- Film Application: A wrapping head, carrying a roll of stretch film (often incorporating Volatile Corrosion Inhibitors - VCI), orbits around the component as it rotates.

- Full Coverage: The combination of component rotation and the orbiting wrapping head ensures complete, tightly-applied coverage of the product's surfaces with the protective film.

- Stability: The vertical orientation and robust roller system maintain stability throughout the wrapping cycle, preventing vibration or shifting even with heavy loads.

3. Key Technical Parameters (Typical Range)

While specifications vary by model, typical parameters for such machines include:

- Bearing/Flange Outer Diameter (OD) Range: 500mm - 3000mm+

- Bearing/Flange Inner Diameter (ID) Range: 300mm - 2500mm+

- Component Width/Height Range: 50mm - 500mm+

- Maximum Load Capacity: 500kg - 5000kg+

- Roller Speed: Adjustable (e.g., 1-4 m/min)

- Ring Turning Speed: Adjustable (e.g., 20-90 r/min)

- Wrapping Material: Stretch Film, VCI Stretch Film, PE Film

- Control System: PLC with HMI (Touch Screen) interface

4. Advantages of Vertical Bearing Wrapping

Employing a vertical wrapping machine offers significant benefits:

- Superior Protection: Creates a complete, cocoon-like wrap, shielding against moisture, dust, and corrosion (especially when using VCI film).

- Enhanced Stability: The vertical orientation and roller support provide a stable platform, crucial for heavy and large-diameter items. The design minimizes vibration and摇晃 (shaking).

- Operational Efficiency: Automates a labor-intensive process, increasing throughput compared to manual wrapping.

- Material Optimization: Controlled film stretch ensures efficient material usage.

- Improved Safety: Reduces manual handling requirements for bulky items.

- Versatility: Suitable not only for bearings but also for flanges, large rings, wire coils, and other heavy, ring-shaped products.

5. Operational Considerations

When implementing or operating such equipment, consider:

- Integration: How the machine fits into the overall production or outbound logistics flow.

- Film Selection: Choosing the right type and gauge of stretch film (with or without VCI) based on protection requirements and environmental conditions. (Understanding VCI technology is key - find reputable resources for detailed information on VCI mechanisms.)

- Maintenance: Regular checks of rollers, drive systems, and the wrapping head are essential for reliable operation.

- Operator Training: Ensuring personnel are properly trained on safe operation and parameter adjustments.

6. Conclusion

Vertical wrapping machines represent a specialized and effective solution for packaging large, heavy bearings, flanges, and similar ring-shaped industrial components. They address critical protection needs while improving operational efficiency and safety, ensuring these valuable parts reach their destination in optimal condition.

Learn more about specialized Bearing Packing Machine solutions.