Automatic steel wire coiling machines represent a cornerstone technology in modern wire processing industries. These sophisticated systems are engineered to transform raw steel wire into precisely wound coils, essential components in countless applications ranging from spring manufacturing to construction materials. This article delves into the technical intricacies, design considerations, operational capabilities, and practical applications of these indispensable industrial machines, aligning with the detailed focus expected by Machine Design readers.

1. Engineering Design and Structural Integrity

The design philosophy behind automatic steel wire coiling machines prioritizes robustness, precision, and automation efficiency. Key considerations include:

- Frame Construction: Typically fabricated from heavy-gauge steel plates and structural profiles, the frame provides the necessary rigidity to withstand operational vibrations and ensure long-term alignment accuracy. Finite Element Analysis (FEA) is often employed during the design phase to optimize structural integrity and minimize deflection under load.

- Modularity: Modern designs often incorporate modular components, facilitating easier maintenance, upgrades, and customization to specific production requirements.

- Component Integration: Careful integration of feeding, straightening, winding, cutting, and control systems is crucial for seamless operation and high output quality.

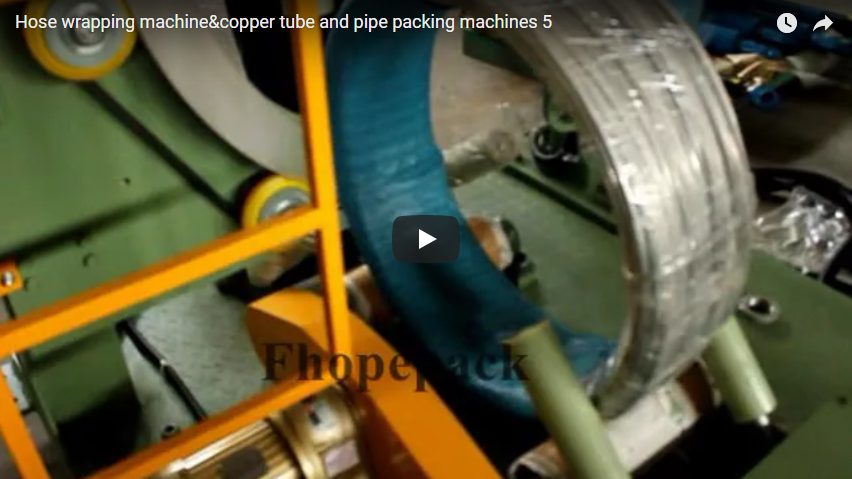

steel wire

(Suggested Image: A CAD rendering or photo highlighting the machine's main structural frame. Alt Text: Robust steel frame of the automatic steel wire coiling machine designed for stability.)

2. Core Components and Functionality

Understanding the primary components provides insight into the machine's operational capabilities:

- Wire Pay-off System: This unit securely holds the bulk wire spool (often weighing hundreds of kilograms) and ensures smooth, tension-controlled de-reeling to prevent tangles or wire damage. Active or passive tension control mechanisms are employed depending on the required precision.

- Wire Straightening Unit: Essential for achieving consistent coil geometry, this unit typically consists of multiple adjustable rollers arranged in perpendicular planes. These rollers precisely bend the wire past its elastic limit to remove inherent cast and curvature. The number and configuration of rollers depend on the wire diameter and material properties.

- Feeding Mechanism: Precision servo-driven rollers or caterpillar-style feeders grip the wire and push it forward at a controlled velocity. Encoders provide feedback to the control system, ensuring accurate length measurement (+/- tolerance typically within millimeters).

- Coiling Head/Mandrel: This is where the coil formation occurs. The design varies based on the application – fixed or adjustable diameter mandrels, driven or passive systems. The geometry and surface finish are critical for producing uniform coils without damaging the wire surface.

- Cutting System: A high-speed shear, typically hydraulic or servo-actuated, cuts the wire cleanly once the desired length or coil size is reached. Blade material (e.g., high-speed steel, carbide) and design are chosen for durability and cut quality based on the wire specifications.

- Control Panel (HMI): A touch-screen interface allows operators to input parameters (length, coil diameter, speed, batch count), monitor the process, receive diagnostic feedback, and manage production recipes.

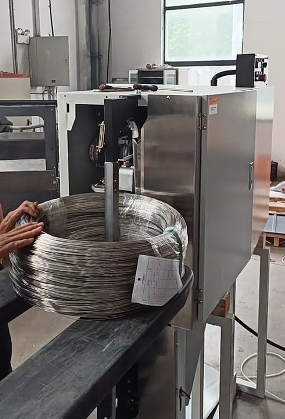

(Suggested Image: Close-up photos of the straightening rollers and the coiling head/mandrel. Alt Text 1: Multi-roller wire straightening unit for precision wire preparation. Alt Text 2: Detailed view of the coiling mandrel forming a steel wire coil.)

3. Control Systems and Automation

The heart of the machine lies in its Programmable Logic Controller (PLC) based control system:

- PLC: Coordinates all machine functions, executing the programmed sequence based on operator inputs and sensor feedback. Common industrial PLC brands (e.g., Siemens, Allen-Bradley, Mitsubishi) are often used, offering robust performance and integration capabilities. [Link to relevant internal page about automation control systems]

- Servo Drives and Motors: Provide precise control over feeding speed, coiling rotation, and cutter actuation, enabling high accuracy and repeatability.

- Sensors: Various sensors monitor critical parameters:

- Length Encoders: Measure the exact length of wire fed.

- Diameter Sensors (Optional): Laser or contact sensors can monitor coil diameter in real-time.

- Presence Sensors: Detect wire presence, coil completion, and potential jams.

- Safety Sensors: Interlocks on guards, light curtains, and emergency stop buttons ensure operator safety according to relevant standards [Link to external source like OSHA or ISO safety standards].

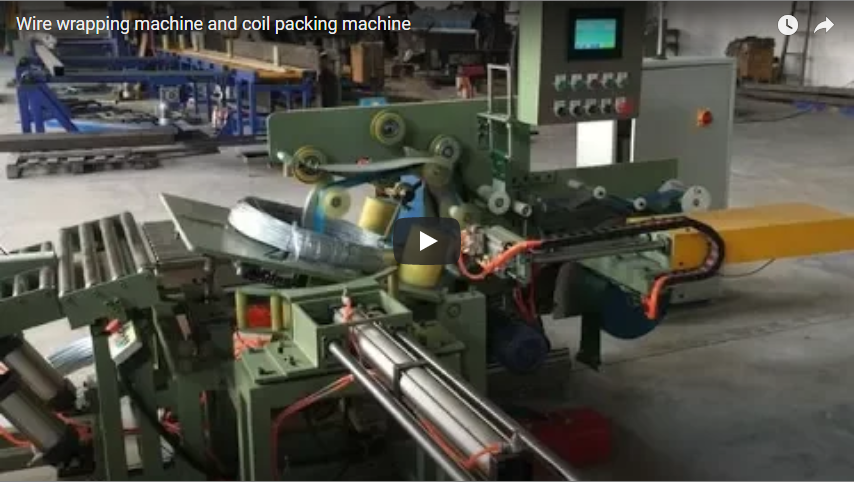

automatic steel wire winding with strapping machines 4. Technical Specifications Overview

The following table outlines typical parameters for automatic steel wire coiling machines. Note that specific values vary significantly based on the model and intended application.

| Parameter | Typical Range/Specification | Engineering Significance |

|---|---|---|

| Wire Diameter Range | 0.5mm - 12mm (Model Dependent) | Determines machine size, power, and straightening capability |

| Wire Materials | Carbon Steel (Low, Medium, High), Stainless Steel, Galvanized Steel, Copper Alloys, Aluminum Alloys | Influences straightener design, cutting force, tooling |

| Coil Inner Diameter (ID) | Adjustable, e.g., 100mm - 1000mm+ | Dictates mandrel size and adjustment mechanism complexity |

| Coil Outer Diameter (OD) | Up to 1500mm+ | Impacts machine footprint and coil handling systems |

| Coil Weight Capacity | Up to 2000kg+ | Governs frame strength, pay-off, and handling design |

| Coiling Speed | Up to 100 m/min (Wire Linear Speed) | Key productivity indicator, limited by mechanics & control |

| Length Accuracy | Typically ± 0.1% to ± 0.5% | Critical for applications requiring precise component lengths |

| Control System | PLC with Touch Screen HMI | Standard for flexibility, monitoring, and ease of use |

| Power Requirements | 3-Phase, 220V/380V/480V, 50/60Hz (Customizable) | Dependent on motor sizes and heating elements (if any) |

| Safety Features | Full Guarding, E-Stops, Safety Interlocks | Compliance with CE, OSHA, or other regional standards |

Disclaimer: The parameters listed above are indicative. For exact specifications matching the machine shown in the video or for a custom configuration tailored to your needs, please contact us directly. [Link to internal contact page]

5. Key Industrial Applications

The versatility of automatic steel wire coiling machines lends them to numerous industrial uses:

- Spring Manufacturing: Producing coils destined to become compression, extension, and torsion springs. The machine's ability to control wire feed length and coil diameter precisely is paramount for achieving the required spring rates and load characteristics used in automotive suspensions, industrial valves, and consumer products. High-speed capability directly translates to lower cost per spring.

- Wire Forming and Fabrication: Creating reinforcement rings for concrete pipes, coiled wire for fencing production (barbed or mesh), or elements for wire baskets and displays. The machine's capacity to handle larger diameters and heavier coils, along with robust cutting systems, is crucial here.

- Electrical Component Production: Winding resistive heating elements or large-gauge inductor coils. While less common for fine-wire magnetics (which use specialized winders), these machines handle heavier gauge wire used in industrial heating and power electronics. Material compatibility (e.g., nichrome, copper) and consistent winding tension are key factors.

- Construction Materials: Coiling wire used in pre-stressed concrete (PC wire) or creating hoops for reinforcing structural elements. Durability and the ability to handle high-tensile materials are essential.

6. Operational Considerations and User Experience

While highly automated, efficient operation involves several factors:

- Setup and Changeover: Well-designed machines allow for relatively quick changeovers between different wire diameters and coil specifications, often facilitated by recipe storage in the HMI and quick-change tooling.

- Operator Training: Operators need training on using the HMI, performing basic setup adjustments, loading wire spools safely, and recognizing potential issues.

- Maintenance: Regular preventive maintenance is crucial for longevity and consistent performance. This includes lubrication of moving parts, inspection of straightening rollers and cutting blades for wear, and calibration checks of the feeding system. [Link to relevant internal page about machine maintenance]

- Troubleshooting: Modern HMIs provide diagnostic information to help pinpoint issues like wire jams, sensor faults, or drive errors, reducing downtime.

7. Benefits of Automation

Investing in an automatic steel wire coiling machine offers significant advantages:

- Increased Productivity: Continuous, high-speed operation far exceeds manual coiling capabilities.

- Improved Consistency & Quality: Automated control ensures uniform coil dimensions (length, diameter) and tightness, reducing variations and scrap rates.

- Reduced Labor Costs: A single operator can often oversee multiple machines or perform other tasks while the machine runs.

- Enhanced Safety: Enclosed designs and integrated safety features protect operators from moving parts and potential hazards associated with manual handling of heavy wire.

- Material Savings: Precise length control minimizes wire wastage compared to less accurate methods.

8. Conclusion

Automatic steel wire coiling winding machines are sophisticated pieces of engineering designed for efficiency, precision, and reliability in demanding industrial environments. From their robust structural design and precisely controlled components to their advanced automation systems, these machines provide essential capabilities across diverse manufacturing sectors. Understanding their technical specifications, operational nuances, and application benefits is key for engineers and production managers looking to optimize wire processing operations.