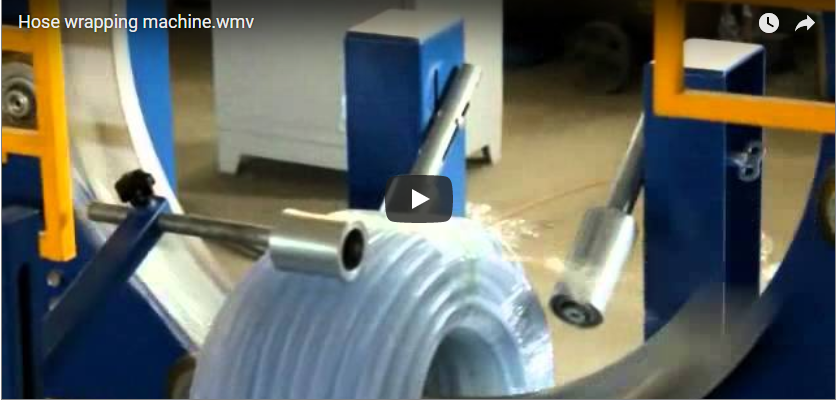

Enhancing Packaging Efficiency: A Technical Overview of FHOPE's Automatic Hose Coil Wrapping Machine

In today's demanding manufacturing landscape, optimizing packaging processes is paramount for achieving operational excellence and maintaining a competitive edge. Manual or semi-automatic hose coil packaging often presents significant challenges, including high labor costs, inconsistent wrap quality, potential for product damage, and workflow bottlenecks. Addressing these industry pain points, FHOPE has engineered a state-of-the-art, fully automatic hose coil wrapping and packing machine designed specifically for efficient handling of small to medium coil sizes.

The Imperative for Automation in Hose Packaging

Traditional hose packaging methods are frequently labor-intensive, requiring operators to manually handle, wrap, and secure coils. This not only incurs substantial labor costs but also introduces variability in packaging quality and poses ergonomic risks. Industry analysis, often highlighted in publications like Packaging World and Industrial Automation Magazine, consistently points towards automation as a key driver for enhancing throughput, ensuring product integrity, and improving workplace safety in packaging lines. The repetitive nature of coil wrapping makes it an ideal candidate for robotic and automated solutions.

FHOPE's Integrated Solution: Design and Technology

The FHOPE automatic hose packing machine represents a significant leap forward, integrating intelligent automation with robust mechanical design. Central to its operation are several key technological components:

1. Automated Infeed and Positioning System

The system features a powered conveyor designed for seamless integration into existing production lines. Upon arrival, coils are automatically transported to the wrapping station. A sophisticated auto-pulling and centering mechanism, often employing optical sensors and PLC (Programmable Logic Controller) logic similar to systems described in patents related to automated material handling (e.g., referencing concepts in USPTO Class B65H), ensures precise coil positioning. This accuracy is critical for consistent wrapping and subsequent processing.

- Mechanism: Servo-driven or pneumatic actuators for precise coil placement.

- Control: PLC-based system synchronizes conveyor speed and positioning arms.

- Benefit: Eliminates manual handling at the wrapping station, reduces cycle time, and prevents misalignment errors.

2. Advanced Coil Wrapping Technology

The core of the machine lies in its orbital wrapping unit. This system utilizes stretch film or other specified wrapping materials (like VCI films for corrosion protection) to securely envelop the hose coil.

- Tension Control: Electronically controlled film tension adjustment ensures optimal wrap tightness without damaging the hose material. This often involves feedback loops using load cells or motor torque monitoring, techniques validated in numerous packaging research papers focusing on film application dynamics.

- Variable Overlap: The degree of film overlap can be programmed via an HMI (Human Machine Interface), allowing customization based on coil dimensions and required protection levels.

- Automatic Film Cut and Clamp: The machine automatically cuts the film upon cycle completion and securely clamps the tail, ensuring a clean finish and readiness for the next cycle.

3. Integrated Outfeed and Labeling (Optional)

Post-wrapping, the machine can integrate with automated labeling systems and outfeed conveyors, facilitating a fully hands-off process from production to palletizing. Data integration capabilities allow for tracking and logging of packaged coils, aligning with Industry 4.0 principles.

Key Operational Advantages and Technical Specifications

Implementing the FHOPE automatic hose coil wrapping machine translates into measurable operational benefits:

- Drastic Labor Reduction: Minimizes the need for manual intervention, potentially reallocating personnel to higher-value tasks. Studies often show automation in packaging can reduce direct labor by 50-80% for specific tasks.

- Enhanced Throughput: Continuous, automated operation significantly increases the number of coils packaged per hour compared to manual methods.

- Consistent Quality: Uniform wrapping tension and placement ensure every coil is packaged to the same high standard, enhancing product protection and brand presentation.

- Improved Safety: Reduces risks associated with manual lifting and repetitive motions.

- Material Savings: Precise control over film usage and overlap minimizes waste.

Technical Parameters Overview:

- Applicable Coil Sizes: Configurable for various Inner Diameters (ID), Outer Diameters (OD), and Heights (customizable).

- Wrapping Materials: Stretch Film (LLDPE), VCI Film, Paper, etc.

- Control System: Typically Siemens or Allen-Bradley PLC with touchscreen HMI.

- Positioning Accuracy: High precision, often within millimeters.

- Wrapping Speed: Adjustable RPM, dependent on coil size and wrap requirements.

- Power/Air Requirements: Standard industrial specifications (e.g., 380V/50Hz, 0.5-0.7 Mpa).

Versatility Across Industries

The machine's adaptability makes it suitable for a wide array of sectors relying on coiled hoses, including:

- Automotive Manufacturing

- Hydraulic and Pneumatic Systems

- Gardening and Agriculture

- Construction and Infrastructure

- Industrial Maintenance and Repair (MRO)

Conclusion

The FHOPE full-automatic hose coil wrapping packing machine offers a robust, technologically advanced solution for companies seeking to optimize their packaging operations. By integrating intelligent automation, precision engineering, and user-friendly controls, this system delivers significant improvements in efficiency, consistency, cost-effectiveness, and safety. It stands as a prime example of how targeted automation can overcome traditional packaging challenges in the hose industry.

For more detailed specifications and to discuss how this solution can be tailored to your specific requirements, please visit our dedicated page:

https://www.fhopepack.com/Hose-packaging-machine/

Or contact our technical team directly:

info@fhopepack.com