Streamlining Extrusion Finishing: The Rise of Automatic Aluminum Profile Bundling Lines

Aluminum extrusions form the backbone of countless applications across construction, automotive, and industrial sectors. However, the final stage of production – packaging – often represents a significant bottleneck, relying heavily on manual or semi-automated processes. As market demands intensify and labor costs escalate, manufacturers are increasingly turning to advanced automation, specifically automatic aluminum profile bundling packaging lines, to gain a competitive edge.

Insights from industry analysis, such as reports from Mordor Intelligence on the packaging machinery market, highlight a consistent trend towards automation driven by the need for higher throughput, reduced operational costs, and improved package quality. Manual packaging methods, while traditional, present several inherent challenges in the context of modern aluminum extrusion facilities.

The Limitations of Traditional Packaging Methods

While effective in low-volume scenarios, manual and semi-automatic packaging of aluminum profiles struggle to keep pace with high-output extrusion lines. Key drawbacks include:

- Labor Intensity and Cost: Manual handling, bundling, wrapping, taping, and cutting are labor-intensive. Rising wages and potential labor shortages directly translate to high and often unpredictable packaging costs per profile. Research consistently points to labor as a primary driver for automation adoption in manufacturing environments.

- Inconsistent Quality: Manual application of stretch film or strapping can lead to variations in tension, bundle security, and overall package appearance. This inconsistency can compromise profile protection during transit and storage, potentially leading to scratches or damage.

- Throughput Constraints: Manual processes inherently limit the speed at which profiles can be packaged, creating a bottleneck that can throttle overall plant efficiency, especially when dealing with high-volume orders.

- Ergonomic and Safety Risks: Repetitive manual lifting, bending, and manipulating long or heavy aluminum profiles pose significant ergonomic risks to workers, potentially leading to injuries and associated costs.

The Automated Solution: Functionality and Technology

An automatic aluminum profile bundling packaging line integrates several processes into a seamless, automated workflow, drastically reducing manual intervention. The core operational sequence typically involves:

- Infeed and Profile Collation: Profiles are received from the extrusion line or staging area, often via automated conveyors, and gathered into predetermined bundle sizes. Sensors ensure accurate counts and proper alignment.

- Automatic Bundling/Strapping: The collated profiles are automatically secured using strapping materials (like PP or PET) or sometimes initial layers of stretch film. This step ensures the bundle maintains its shape for subsequent wrapping. Technologies referenced in patents (e.g., relating to automated strapping heads like US Patent 9,481,491 B2, though for general purposes) often focus on reliability and speed.

- Stretch Wrapping Application: The secured bundle moves into a wrapping station, typically featuring a ring-style or orbital stretch wrapper. A carriage dispenses stretch film, applying it around the bundle with precisely controlled tension and overlap. Advanced systems may incorporate features described in research papers on film stretching mechanics to optimize material usage and load containment.

- Film Cutting and Sealing: Once wrapping is complete, the film is automatically cut and secured (often using heat sealing or clamping mechanisms) to prevent unraveling.

- Bundle Ejection: The finished, wrapped bundle is automatically ejected onto an exit conveyor or staging area, ready for labeling, palletizing, or direct shipment.

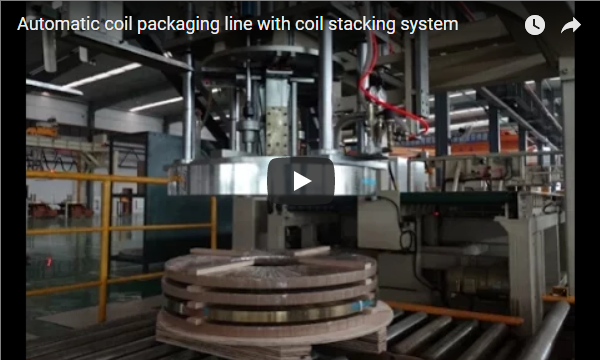

automatic aluminum profile bundling packaging line

Modern systems are typically governed by Programmable Logic Controllers (PLCs) and feature Human-Machine Interfaces (HMIs) for easy operation, parameter adjustment (e.g., bundle size, wrap cycles, film tension), and diagnostics. Integration with plant-level Manufacturing Execution Systems (MES) or Enterprise Resource Planning (ERP) systems is increasingly common, enabling real-time data tracking and production management, aligning with Industry 4.0 principles discussed in publications like Control Engineering.

Tangible Benefits for Aluminum Extruders

Investing in an automatic bundling and packaging line offers significant, measurable advantages:

- Drastic Labor Reduction: Automating the packaging process can reallocate multiple workers per shift to higher-value tasks, directly impacting the bottom line. Industry case studies frequently report labor savings exceeding 50-70% in packaging operations post-automation.

- Increased Throughput: Automated lines operate continuously at speeds significantly faster than manual methods, eliminating bottlenecks and aligning packaging capacity with extrusion output.

- Consistent Package Quality & Protection: Precise control over bundling and film tension ensures every package is uniform, secure, and offers optimal protection against scratches, abrasions, and environmental factors during handling and transport. This reduces costly damage claims and enhances customer satisfaction.

- Optimized Material Usage: Automated stretch wrappers apply film consistently, often incorporating pre-stretch capabilities (stretching the film before application) which can reduce film consumption by 50% or more compared to manual wrapping, according to film manufacturers' data.

- Enhanced Workplace Safety: Eliminating manual lifting and repetitive motions significantly improves ergonomics and reduces the risk of workplace injuries.

- Space Efficiency: Integrated lines often have a smaller footprint compared to the sprawling space required for manual packing stations and staging areas.

- Rapid Return on Investment (ROI): While requiring initial capital expenditure, the combined savings in labor, materials, damage reduction, and increased efficiency typically lead to a compelling ROI, often realized within 1-3 years.

Implementation Considerations

Successfully integrating an automatic packaging line requires careful planning:

- Line Layout and Integration: Ensuring smooth flow from upstream processes (e.g., cutting, finishing) and to downstream logistics (e.g., warehousing, shipping).

- Profile Variability: Selecting a system flexible enough to handle the range of profile shapes, lengths, and bundle configurations produced.

- Operator Training: Equipping staff with the skills to operate, monitor, and perform basic maintenance on the new equipment.

- Maintenance Strategy: Implementing a preventative maintenance schedule to ensure long-term reliability and performance.

Partnering for Packaging Excellence

Manufacturers like FHOPE specialize in designing and building robust automatic aluminum profile bundling packaging lines tailored to the specific needs of the aluminum extrusion industry. Collaborating with experienced automation partners ensures the selected solution effectively addresses production goals and integrates seamlessly into existing operations.

Investing in packaging automation is no longer just an option for large-scale aluminum extruders; it's becoming a strategic necessity for enhancing efficiency, ensuring quality, managing costs, and maintaining competitiveness in a demanding global market.

For more technical specifications and solution examples, explore FHOPE's automatic aluminum profile bundling packaging line offerings.