Click to Chat

I'm online now.

Fhopepack Innovation

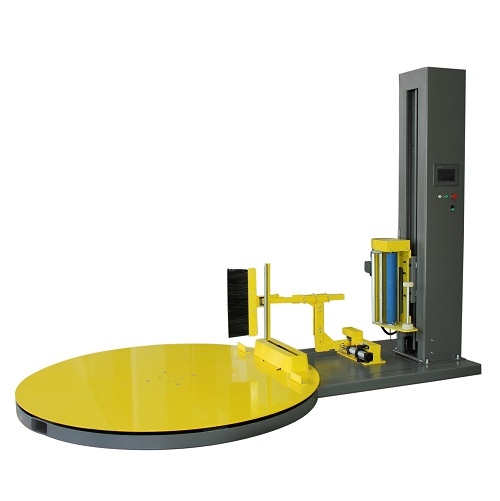

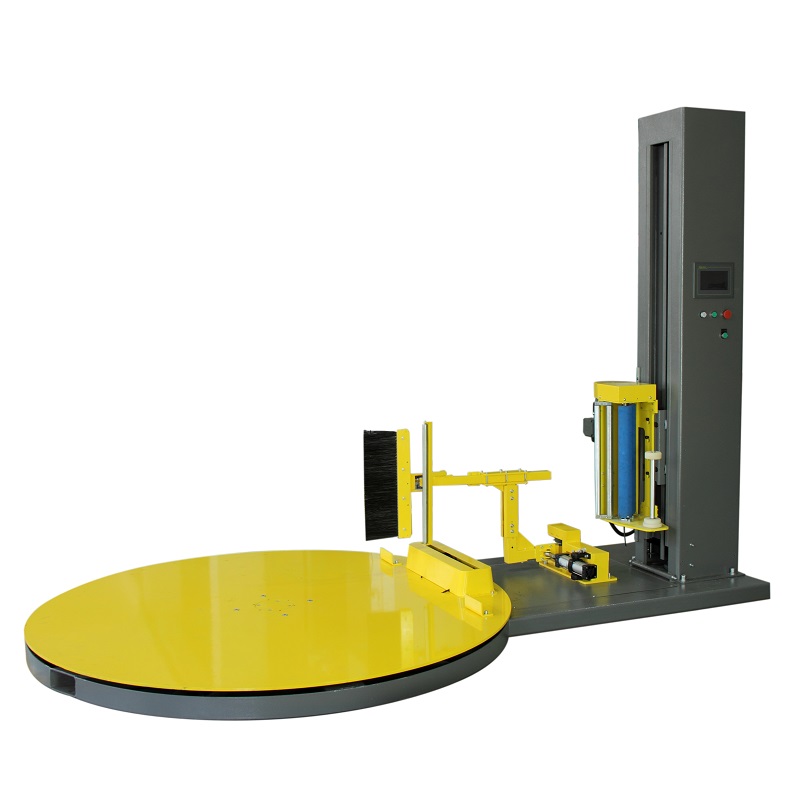

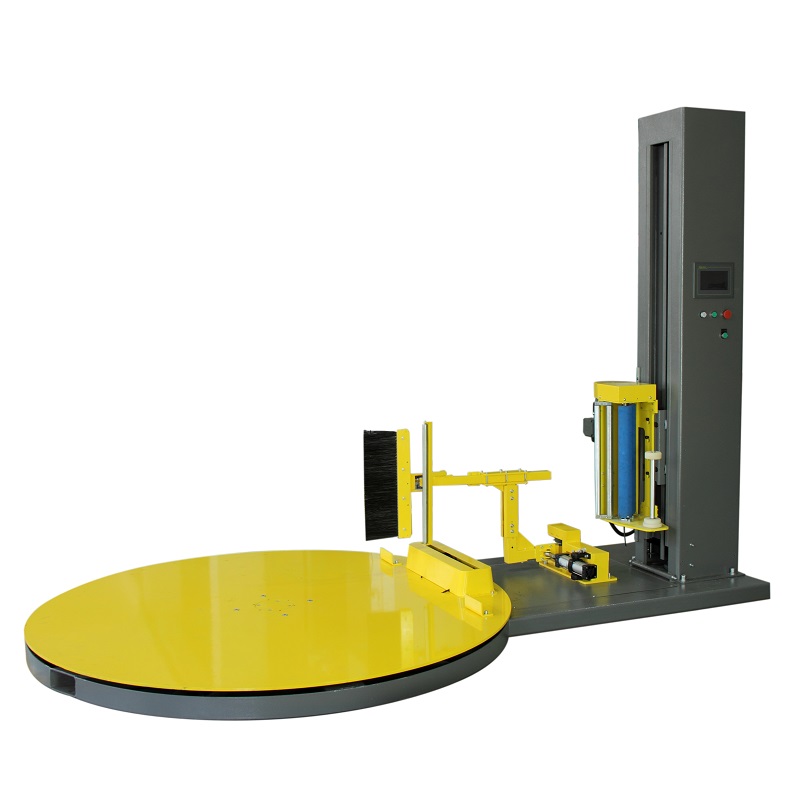

Pallet stretch wrap machine features adjustable specifications for pallet wrapping and load size. It also comes equipped with strong pallet supportive rollers inside the turntable, ensuring reliable and efficient performance during operation. With its durable and reliable structure, our pallet stretch wrap machine is designed for long-lasting use, providing businesses with a cost-effective and eff

Controller: PLC system

Tension control: Pre-stretch controller

Operator interface: Separate buttons/Display

Wrap settings: Re-wrap function, overwrap and overlap adjustments

Wrap counters: Independent top, middle and bottom

Cycle counters: Total cycle counter and resettable Counter

Emergency stop: Red mushroom head

Electrical disconnect: Lockable

Electrical enclosure: European approved

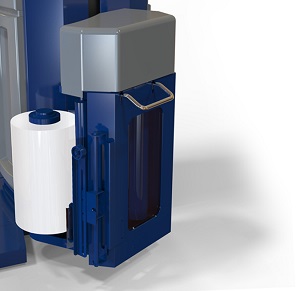

Film Delivery System

Stretch Film (LLDPE):

Thickness: 0.025mm ,

Width: 500mm

Length : 500m-1500m,

Weight: 15kg/Roll

Film capacity: 500mm width x 76mm dia.

Stretch type: Pre-stretch

Pre-stretch level: 250% (optional 100% to 300%)

Load height sensor: Photocell sensor

Force -control: Variable

Film threading: Fhope design, W film threading pattern.

Start & stop mode: Soft start & stop

Diameter: 1650mm

Maximum turning diameter: 2000mm

Maximum load weight: 2000kg

Turntable elevation: 80mm

Turntable plate thickness: 10mm (Anti-deformation)

| Item\data | A300 |

| Size of the product to be wrapped(adjustable) | |

| MAX load size(L*W*H) | 1500mm*1500mm |

| Min load size(L*W*H) | 500 * 500 * 500 mm |

| Max load height | 1800mm |

| Max weight | 2000kg |

| Machine Specification | |

| Turntable rotation speed | 13r/min(adjustable) |

| Turntable diameter | 2000mm |

| Turntable height | 100mm |

|

Carriage Up/down speed |

adjustable |

|

Power supply voltage (adjustable) |

Standard 220 Volt 1 Ph-50 Hz |

| Tower motor power | 0.4w |

| Pre-stretch motor power | 0.35w |

| Turntable motor power | 0.75w |

| Packing efficiency | 20-40 loads/hour |

| Forklifting | front & rear |

| Machine weight | 650kg |

| PLC control | ▲ |

| Film sealer | / |

| HMI | ▲ |

| Pre-stretch | ▲ |

| Stretch Film Roll detail | |

| External diameter | 150-250mm |

| Internal diameter | 76 |

| Film roll height | 500m |

| Film thickness | 0.025mm |

I'm online now.