httpv://youtu.be/xxxxxx

Replace xxxxxx above with the actual YouTube Video ID.

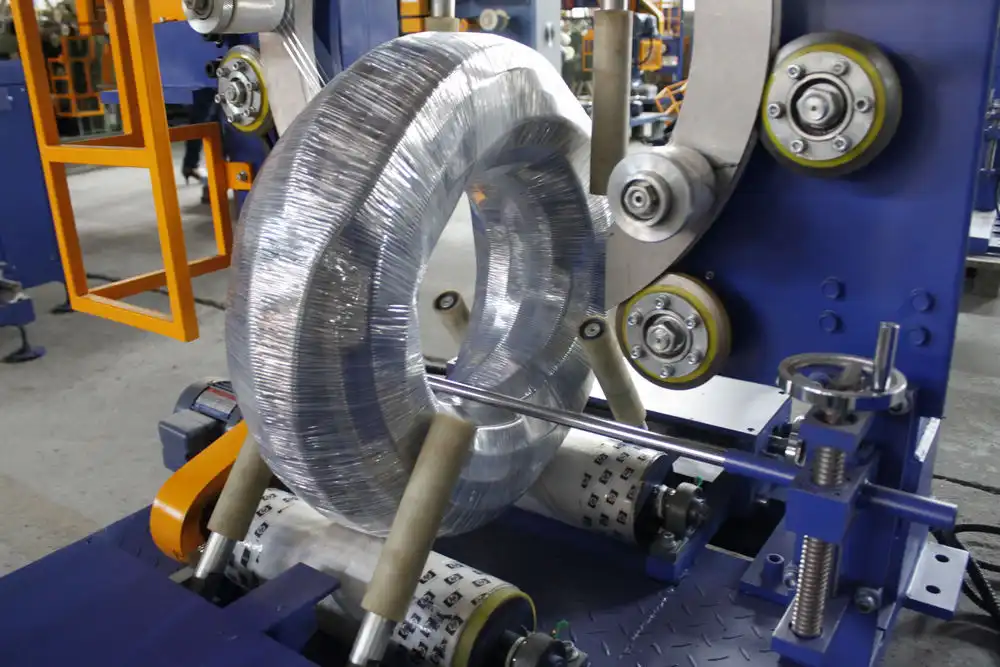

Optimizing Coil Protection: Selecting the Right Stretch Film for Industrial Applications

In modern manufacturing and distribution, ensuring the integrity of coiled products during handling, storage, and transit is paramount. Coils, whether metal, wire, cable, hose, or other materials, are susceptible to damage from moisture, dust, abrasion, and shifting. Stretch film, specifically engineered Linear Low-Density Polyethylene (LLDPE), has become an indispensable tool for providing robust protection and unitization. Understanding the properties and selection criteria for stretch film is crucial for operational efficiency and minimizing product loss.

### Understanding Stretch Film: Material Science and Production Insights

Stretch film, often referred to as stretch wrap, is predominantly manufactured from LLDPE resins. Its defining characteristic is high elasticity, allowing it to be stretched significantly around a load, utilizing its elastic recovery to create secure containment.

**Production Processes & Film Types:**

The manufacturing process significantly influences film properties. Key methods include:

1. **Cast Extrusion:** Resin is extruded through a flat die onto chilled rollers. This process generally yields film with excellent clarity, quiet unwind, and good cling properties, often preferred for warehouse environments. Multi-layer co-extrusion (often 5-7 layers or more, sometimes incorporating nano-layer technology referenced in materials research) allows specific properties like enhanced puncture resistance or cling on one side only.

2. **Blown Extrusion:** Resin is extruded through a circular die and inflated into a bubble, which is then cooled and collapsed. Blown films typically offer higher puncture and tear resistance compared to cast films of equivalent gauge, albeit with lower clarity and often a noisier unwind. This toughness can be advantageous for irregular or sharp-edged coils.

The orientation process (stretching the film during manufacturing) aligns the polymer molecules, enhancing tensile strength and load-holding capabilities.

### Critical Performance Parameters for Coil Wrapping Film

Selecting the appropriate stretch film requires understanding key technical specifications, often benchmarked against ASTM standards. For an 80-gauge (20.3 micron) film, typical performance metrics relevant to coil wrapping include:

* **Ultimate Tensile Strength (MD/TD):** Measures the maximum stress the film can withstand before breaking when stretched longitudinally (Machine Direction - MD) or transversely (Transverse Direction - TD). High MD strength (e.g., 6800 psi) is crucial for resisting forces during the wrapping cycle. (Ref: ASTM D882)

* **MD:** 6800 psi

* **TD:** 5600 psi

* **Elongation (MD/TD):** Indicates the percentage the film can stretch before breaking. High elongation (e.g., MD 670%, TD 825%) allows the film to conform tightly to the coil shape. (Ref: ASTM D882)

* **MD:** 670%

* **TD:** 825%

* **Tear Resistance (MD/TD):** Measures the film's ability to resist the propagation of a tear once initiated. Higher values (e.g., TD 618 grams) are critical for preventing small punctures from becoming large failures, especially relevant for potentially sharp metal coil edges. (Ref: ASTM D1922)

* **MD:** 175 grams (218.75 g/mil)

* **TD:** 618 grams (772.5 g/mil)

* **Dart Drop (Puncture Resistance):** Measures the energy required to puncture the film. A higher value (e.g., 180 grams) indicates better resistance to penetration from sharp corners or handling equipment. (Ref: ASTM D1709)

* **Value:** 180 grams (225 g/mil)

* **Pre-stretch Potential:** Indicates the maximum percentage the film can be elongated by powered stretch wrapping equipment before breaking, while maintaining load integrity. A high value (e.g., 325%) enables material savings by using less film per load.

* **Value:** 325%

* **Cling:** The property that allows the film to adhere to itself without adhesives. Measured force (e.g., 350 grams at 200% pre-stretch) ensures layers bond effectively for a secure wrap.

### Stretch Film Specifications Tailored for Coil Wrapping Machinery

Compatibility between the stretch film roll and the wrapping equipment is essential for smooth operation. Key dimensional parameters include:

* **Film Roll Outer Diameter (OD):** Typically 100-200 mm, dictated by the machine's film carriage capacity.

* **Film Roll Inner Diameter (ID) / Core Size:** Standard cores are 50 mm (2 inches) or 76 mm (3 inches). Must match the machine's mandrel.

* **Film Width:** Commonly ranges from 50 mm to 150 mm for specialized coil wrappers, allowing focused wrapping around the coil's profile. Wider films (e.g., 500mm / 20 inches) are used in orbital wrappers enveloping the entire coil.

* **Film Thickness (Gauge):** While 80 gauge (20.3 microns) is common, a **minimum thickness of >25 microns (approx. 100 gauge)** is often recommended for robust coil protection, especially for heavier or sharp-edged products, to ensure adequate puncture and tear resistance. Thicker films (up to 120 gauge or more) may be necessary for demanding applications.

### Strategic Benefits of Stretch Film in Coil Packaging Logistics

Employing the correct stretch film for coil packing delivers significant operational and financial advantages:

* **Enhanced Product Protection:** Creates a tight barrier against environmental contaminants like moisture (preventing rust on metal coils), dust, and dirt. Specialized films can offer UV protection for outdoor storage or Volatile Corrosion Inhibitor (VCI) properties for sensitive metals.

* **Superior Load Stability & Containment:** The film's elastic recovery exerts constant tension, securing the coil, preventing layers from shifting (telescoping), and ensuring stability during dynamic transit conditions. This directly reduces damage rates and associated costs. Proper application technique, often achieved via automated [coil packing machines](https://www.fhopepack.com/Coil_packing_machine.html), is key.

* **Increased Operational Efficiency:** Automated and semi-automated coil wrapping systems drastically reduce manual labor requirements and packaging cycle times compared to manual strapping or bagging. Consistent wrap quality is achieved machine-to-machine, improving standardization.

* **Cost-Effectiveness & Source Reduction:** High-performance films, especially when utilized with powered pre-stretch equipment (achieving 200-300% stretch), optimize material usage. This reduces the volume of film consumed per coil compared to lower-stretch films or alternative methods like strapping (which can damage coil edges) or bulky crates, contributing to lower total packaging costs and sustainability goals.

Selecting the Optimal Stretch Film: Key Considerations

Choosing the most effective stretch film involves evaluating several factors:

- Coil Characteristics: Weight, diameter, width, material type (metal, plastic, rubber), and edge condition (sharp vs. smooth). Heavier, larger, or sharper coils typically require thicker gauge films with higher puncture and tear resistance.

- Wrapping Equipment: Manual applicators, semi-automatic turntables, or fully automatic orbital wrappers. Machine capabilities, particularly pre-stretch levels, dictate the type of film that can be used efficiently.

- Load Requirements: Need for simple containment vs. high security, environmental protection (indoor/outdoor storage), or specialized needs like corrosion inhibition.

- Logistics Chain: Duration of storage, mode of transport (road, rail, sea), and handling frequency impact the required level of protection and load stability.

Conclusion: Strategic Importance of Film Selection

Stretch film is more than just a packaging commodity; it's an engineered component critical to protecting valuable coiled assets throughout the supply chain. By carefully considering the material science, performance metrics, application requirements, and available wrapping technologies, distributors and manufacturers can select the optimal stretch film solution. This strategic choice directly impacts product integrity, operational efficiency, cost management, and customer satisfaction in demanding industrial environments.