Every manufacturer knows the pain points—inefficient packing can lead to increased costs, damaged goods, and frustration. Are you constantly worried about your steel coils getting damaged during transit? Efficient packing is the answer.

The best packing material combination for steel coil packing includes a blend of durable materials such as VCI film, steel belts, and edge protectors. These ensure maximum protection against corrosion, mechanical damage, and handling stresses, offering reliable stability and long-term preservation during transit and storage.

Packaging can be challenging, especially with steel coils. Factors like weight, size, and exposure risks can complicate it. Here's how the right material choices can make a significant difference. Keep reading to learn more about optimizing your packing solution.

Key Considerations in Choosing Packing Materials for Steel Coils

Is your packaging as efficient as it could be? Struggles with tight schedules or staying updated with the latest packaging technology can make this decision overwhelming. But the right packing materials can transform your workflow.

When choosing packing materials for steel coils, consider factors like corrosion resistance, mechanical protection, ease of application, and cost-effectiveness. These elements jointly contribute to maintaining product integrity while optimizing resource allocation, ultimately enhancing both operational efficiency and customer satisfaction.

Delving into Material Options for Steel Coil Packing

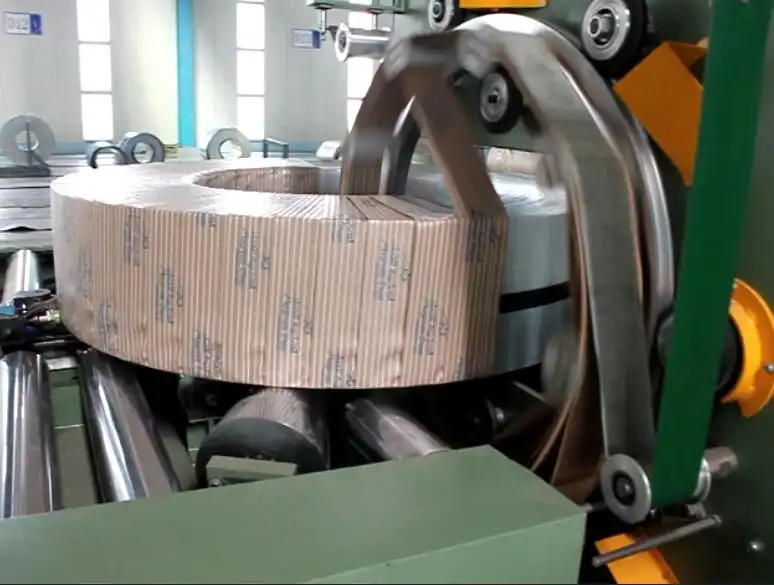

Choosing the right materials requires an analysis of multiple factors. For instance, VCI film is crucial in protecting against corrosion. It creates a barrier that releases corrosion-inhibiting vapors, preventing rust on metal surfaces. Its cost-effectiveness makes it a popular choice. Meanwhile, steel belts offer the strength needed to secure heavy coils during transportation.

Protection is not just about materials; it's also about application methods. Proper wrapping and strapping techniques ensure the stability of the coil. Keep in mind that edge protectors play a pivotal role too. They prevent the steel belts from cutting into the coil and distribute tension evenly. They are essential when dealing with large or heavy coils.

Choosing the suitable material combination is not a one-size-fits-all solution. It varies based on specific needs and operations. However, focusing on these key materials ensures the steel coils arrive in perfect condition, safeguarding your reputation and bottom line. Packaging continues to evolve with technology, and staying informed is vital for optimal results. This understanding aids you in achieving a perfect balance between protection and cost.

With extensive knowledge in the industry, FHOPEPACK is here to aid in selecting the right combination. Our experience shows that effective material selection transforms steel coil packing from a potential liability into a strength.## Comparing Different Packing Materials for Steel Coil Efficiency

Struggling with efficient packing for steel coils? You're not alone. Discover the perfect material to boost efficiency and safety in your packaging process.

Selecting the right packing material for steel coils is crucial for efficiency. Materials like VCI paper, stretch film, and steel straps each offer unique benefits, but the choice depends on specific needs and budget constraints.

Weighing Options: VCI Paper vs. Stretch Film vs. Steel Straps

Let's inspect three main types of materials—VCI paper, stretch film, and steel straps. VCI paper offers excellent corrosion protection but is more costly. Stretch film provides flexibility and a cost-effective option but may lack in providing heavy-duty protection. Steel straps provide strength and durability but add weight and difficulty in handling. Understanding these aspects is key for making an informed decision.

| Material | Pros | Cons |

|---|---|---|

| VCI Paper | Best corrosion protection, easy to use | Expensive, less flexible |

| Stretch Film | Cost-effective, flexible, easy to apply | Limited in strength, less protection |

| Steel Straps | Durable, strong, secure | Heavy, challenging to handle, expensive |

The balance between cost, protection, and ease of application greatly influences the selection of a suitable packing material. It's essential to prioritize what matters most to your operations for optimal results.

Environmental and Cost Implications of Packing Materials

Packaging choices impact more than efficiency. Dive into environmental concerns and cost implications to make smarter, eco-friendly decisions.

Choosing packing materials involves weighing environmental and cost implications. Sustainable options like biodegradable materials may reduce environmental impact but can vary in cost-effectiveness based on use and disposal practices.

Cost vs. Environment: Finding a Balance

Balancing environmental responsibility with budget constraints is a significant challenge. Sustainable materials may offer eco-friendly advantages but often come at a higher initial cost. In contrast, traditional materials can be cheaper in the short term but could incur longer-term environmental costs.

| Aspect | Sustainable Materials | Traditional Materials |

|---|---|---|

| Initial Cost | Typically higher | Usually lower |

| Environmental | Lower carbon footprint, biodegradable | Higher carbon footprint, non-recyclable |

| Long-term Cost | May incur savings from waste management | Potential fines and penalties |

This comparative insight aids in understanding potential impacts on both finances and the planet. Prioritizing long-term sustainability can also lead to cost savings, enhancing your company’s reputation and operational efficiency. Choosing wisely means striking a balance that aligns with your operational needs and values.