Enhancing Steel Wire Packaging: A Deep Dive into Automated Coil Wrapping Technology

Handling and packaging steel wire coils poses significant challenges in the metal fabrication and processing industry. Ensuring product integrity, preventing corrosion, and optimizing logistical efficiency demand robust packaging solutions. Automated orbital wrapping machines, specifically designed for steel coils, represent a critical technological advancement addressing these needs. This technology moves beyond manual methods, offering consistency, speed, and enhanced protection crucial for maintaining product quality from the production line to the end-user.

The Critical Role of Protective Coil Packaging

Steel wire, particularly in coil form, is susceptible to various environmental and physical damages during transit and storage. According to studies published in journals like Materials Performance, inadequate packaging is a primary contributor to surface corrosion, contamination, and mechanical damage (e.g., deformation, scratches). Effective packaging serves multiple purposes:

- Corrosion Prevention: Creates a barrier against moisture, oxygen, and contaminants. The integration of Volatile Corrosion Inhibitor (VCI) films, often cited in packaging research, provides active chemical protection.

- Mechanical Protection: Shields coils from impacts, abrasions, and pressure points common during handling and shipping.

- Load Stabilization: Ensures the coil remains tightly wound and stable, preventing unwinding or shifting, which is crucial for safe transportation and stacking.

- Handling Efficiency: Properly wrapped coils are easier and safer to handle using forklifts or cranes.

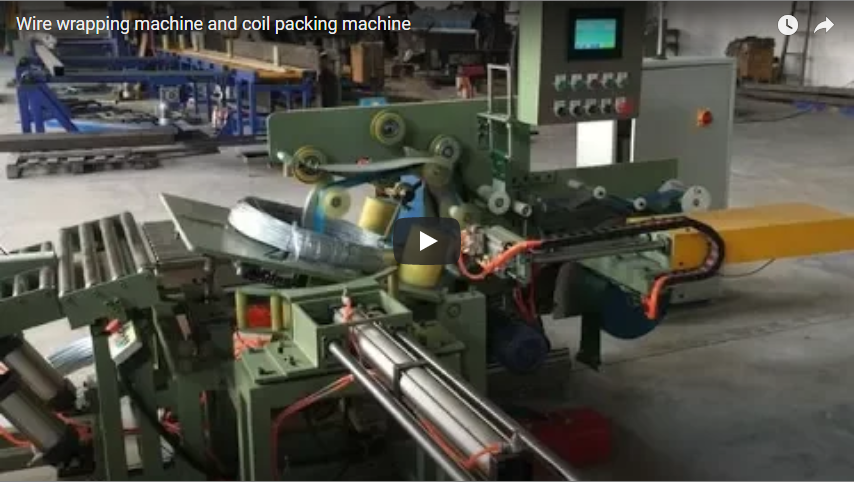

Operational Principles of Steel Wire Coil Wrapping Machines

Modern steel wire coil wrapping machine technology utilizes an orbital wrapping process. The typical operational sequence involves:

- Coil Loading: The steel wire coil is placed onto the machine's loading area, often via conveyor, crane, or forklift.

- Positioning: The coil is centered relative to the wrapping ring.

- Wrapping Cycle Initiation: The operator or an automated system initiates the wrapping sequence via a control panel, typically a Human-Machine Interface (HMI) connected to a Programmable Logic Controller (PLC).

- Film Application: A rotating ring or shuttle dispenses packaging material (commonly stretch film, VCI film, or paper) around the coil's outer surface and through its eye, creating overlapping layers. Advanced systems feature powered pre-stretch mechanisms, as detailed in numerous packaging machinery patents (e.g., USPTO classification B65B 11/04), which can stretch the film up to 300% or more. This optimizes film usage and enhances load containment force.

- Film Cutting and Clamping: Upon cycle completion, an automated system cuts the film tail and secures it against the coil, preventing unraveling.

- Coil Unloading: The fully wrapped coil is removed from the machine, ready for dispatch or storage.

steel wire coil packing machine 2023 Key Technical Features and Specifications

While specific configurations vary, high-performance steel wire coil wrappers often incorporate the following features, reflecting design principles highlighted in industry publications like The Fabricator and Modern Metals:

- Robust Construction: Heavy-duty welded steel frame designed for industrial environments.

- Variable Speed Controls: Adjustable ring/shuttle rotation speed and conveyor speed for process optimization.

- Advanced Control System: PLC control with HMI for intuitive operation, parameter setting (e.g., overlap percentage, wrap counts), and diagnostics.

- Powered Pre-Stretch Carriage: Ensures consistent film stretch ratio, maximizing film yield and load security. Research indicates optimal pre-stretching significantly reduces packaging material costs.

- Coil Compatibility: Designed to handle a range of coil dimensions:

- Inner Diameter (ID): Typically 400mm - 700mm

- Outer Diameter (OD): Typically 700mm - 1600mm

- Width: Typically 100mm - 800mm

- Weight Capacity: From a few hundred kilograms up to several tons.

- Material Versatility: Capable of applying various wrapping materials, including LLDPE stretch film, VCI-impregnated film, paper, or woven fabrics.

- Safety Features: Interlocked guarding, emergency stop buttons, light curtains, and audible alarms adhering to safety standards (e.g., ISO 13849).

- Automation Options: Automatic film cutting and clamping, integration with coil tilters, weigh scales, and plant-wide automation systems.

Tangible Benefits for Metal Fabricators and Processors

Investing in automated steel wire coil wrapping yields significant operational advantages:

- Increased Throughput: High-speed wrapping cycles dramatically reduce packaging time compared to manual methods, boosting overall productivity.

- Reduced Labor Costs: Automation minimizes the need for manual labor in the packaging process, allowing personnel reallocation to higher-value tasks.

- Improved Product Protection: Consistent, tightly applied wrapping layers provide superior protection against moisture, dirt, and physical damage, reducing product rejects and claims. VCI integration offers proven long-term corrosion protection.

- Enhanced Worker Safety: Eliminates strenuous and potentially hazardous manual wrapping tasks, reducing the risk of musculoskeletal injuries.

- Consistent Package Quality: Automated control ensures every coil is wrapped to the same pre-defined specifications, enhancing brand presentation and customer satisfaction.

- Optimized Material Consumption: Pre-stretch systems significantly reduce the amount of film required per coil, leading to substantial cost savings and reduced environmental impact.

Conclusion: A Strategic Investment in Efficiency and Quality

The steel wire coil wrapping machine is far more than just a packaging device; it's a strategic asset for any facility handling steel wire coils. By leveraging automation, advanced material science (like VCI technology), and robust engineering principles often documented in technical papers and patents, these machines deliver measurable improvements in efficiency, safety, and product quality. As highlighted in industry analyses, automation in secondary processes like packaging is key to maintaining competitiveness in the global metals market. This machine provides a reliable, low-maintenance solution that streamlines operations and protects valuable steel wire assets throughout the supply chain.

For more coil wrapping machine, just here