In modern steel tube production, maintaining high output speeds is crucial. However, downstream processes like manual packing often create bottlenecks, limiting overall efficiency and increasing labor costs. An automatic steel tube bundle packing line provides a comprehensive solution, seamlessly integrating with production outflow to handle counting, bundling, strapping, and stacking operations at speeds that match or exceed manufacturing rates. This article delves into the technical specifications, components, design considerations, and operational benefits of such systems, specifically looking at solutions offered by FHOPE.

1. The Challenge: Manual Packing Inefficiencies

Manual handling and packing of steel tubes present several challenges:

- Speed Limitations: Human operators struggle to keep pace with high-speed tube mills.

- Inconsistent Bundling: Variations in bundle tightness, shape, and count can occur.

- Labor Intensity: Requires significant manpower, increasing operational costs.

- Safety Concerns: Manual handling of heavy steel tubes poses ergonomic risks and potential for injury.

- Production Bottlenecks: Packing delays can halt the entire production flow.

2. The Solution: FHOPE Automatic Steel Tube Bundle Packing Line

The FHOPE system is engineered to automate the entire end-of-line process for steel tubes. It receives tubes directly from the production line, accurately counts them, forms them into pre-defined bundle shapes (hexagonal, square, rectangular), securely straps them, and then stacks the finished bundles for storage or transport. This automated workflow significantly enhances throughput and operational efficiency compared to manual methods.

3. Key Components and Functionality Breakdown

A typical FHOPE steel tube bundle packing line comprises several integrated modules:

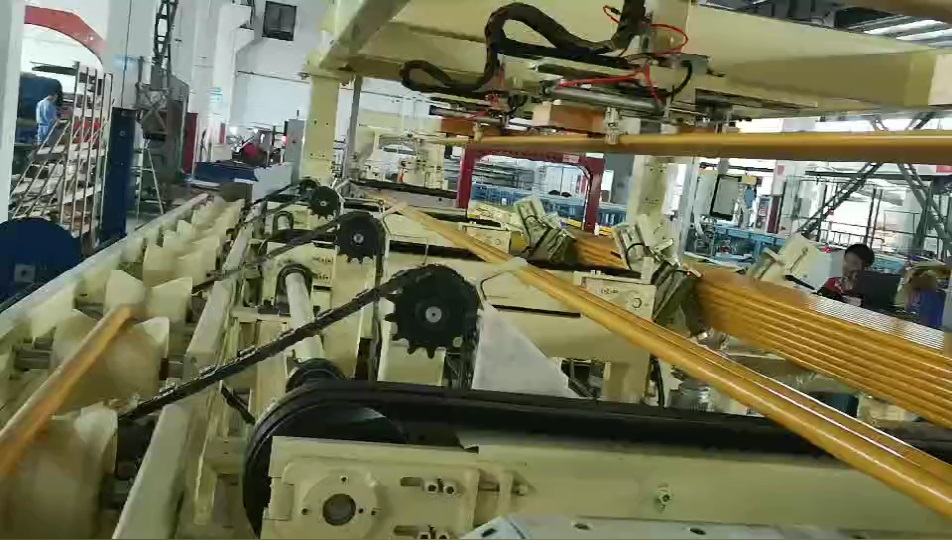

- Infeed Conveyor System: Receives tubes from the production line and transports them smoothly into the system. Design often includes rollers or chain conveyors depending on tube profile and weight.

- Counting and Alignment: Utilizes sensors (photoelectric or laser) and mechanical guides to accurately count tubes and align them for bundle formation. PLC (Programmable Logic Controller) based systems ensure precise counts for each bundle.

- Bundle Formation Station: Mechanical arms or jigs arrange the counted tubes into the desired bundle shape (e.g., hexagonal for round tubes, square/rectangular for profiles). This ensures consistent bundle geometry.

- Strapping Unit: Applies steel or PET strapping circumferentially around the bundle. The number and position of straps are programmable. Tensioning and sealing are automated for secure bundling.

- Optional Wrapping Station: For added protection against corrosion or environmental factors, an orbital stretch wrapper can be integrated to encase the bundle in film.

- Stacking System: Transfers the completed bundles to a designated stacking area. Common types include:

- Fork Arm Stackers: Lift and place bundles layer by layer.

- Magnetic Lifters: Suitable for specific bundle types and weights, offering fast transfer.

- Control System: Typically features a user-friendly HMI (Human-Machine Interface) for setting parameters (bundle size, tube count, strap positions), monitoring operation, and diagnostics.

4. Technical Specifications & Performance Data

Key performance indicators for the FHOPE line include:

- Maximum Line Speed: Up to 120 meters per minute (matching high-speed mill output).

- Bundle Outside Diameter (OD): 400mm - 800mm (adjustable range).

- Bundle Length: 3000mm - 6000mm (standard range, customizable).

- Tube Compatibility: Round, square, rectangular profiles.

- Strapping Material: Steel or PET strapping compatibility.

- Control System: PLC-based with HMI touch screen.

- Power Requirements: Typically 380V/50Hz/3Ph (adaptable).

- Air Pressure: Standard industrial requirement (e.g., 0.5-0.7 MPa).

Note: Specific parameters can be customized based on client requirements.

5. Design Considerations and Structural Integrity

The design emphasizes robustness and reliability for demanding industrial environments:

- Heavy-Duty Construction: Utilizes high-grade steel frames and durable components to withstand continuous operation and heavy loads.

- Modular Design: Allows for flexibility in layout configuration and easier integration with existing plant infrastructure. Future upgrades or modifications are simplified.

- Safety Features: Incorporates safety guarding, emergency stop buttons, light curtains, and interlocks to protect personnel during operation.

- Ease of Maintenance: Designed for accessibility to key components, facilitating routine maintenance and reducing downtime.

6. Operational Advantages and ROI

Implementing an automated packing line delivers significant benefits:

- Increased Throughput: Eliminates packing bottlenecks, allowing the production line to run at its maximum potential speed.

- Reduced Labor Costs: Frees up personnel previously assigned to manual packing for other value-added tasks.

- Improved Bundle Quality: Ensures consistent bundle shape, count accuracy, and secure strapping, reducing damage during handling and transport.

- Enhanced Workplace Safety: Minimizes manual lifting and handling of heavy materials.

- Faster Order Fulfillment: Quicker processing from production to dispatch.

7. User Experience Insights

From an operational standpoint, users often highlight the following:

- Intuitive Controls: The HMI simplifies setup and operation, allowing operators to quickly adjust parameters for different production runs.

- Reliability: Robust design leads to fewer breakdowns and consistent performance shift after shift.

- Reduced Physical Strain: Automation significantly lessens the manual labor involved, improving operator ergonomics and job satisfaction.

- Process Visibility: The control system provides real-time status updates and diagnostic information, aiding in troubleshooting and monitoring.

8. Available Customizations and Stacking Options

FHOPE offers tailored solutions beyond the standard specifications. This includes handling different tube profiles, such as those detailed in the rectangular steel pipe packing line configuration. Stacking options are a key area for customization:

- Fork Arm Stacking: A common and versatile method suitable for various bundle sizes and weights.

- Magnet Type Stacking: Offers potentially faster cycle times for specific applications, particularly with ferrous materials.

- Gantry Systems: For large-scale operations requiring extensive stacking patterns or integration with automated warehousing.

Automation can also extend to include automatic steel belt strapping, providing a complete end-to-end solution without manual intervention.

9. Conclusion: Streamlining Steel Tube Packaging

In conclusion, an automatic steel tube bundle packing line is an essential investment for modern steel tube manufacturers seeking to optimize efficiency, reduce costs, and improve safety. By automating the counting, bundling, strapping, and stacking processes, systems like those from FHOPE eliminate critical bottlenecks, ensure consistent package quality, and allow production facilities to operate at their full potential. The integration of robust design, advanced control systems, and customizable options makes these lines a powerful tool for enhancing competitiveness in the steel industry.