150X150mm rectangular steel pipe packing line.

steel tube packing solution online handling and packing without automatic control system.

The way to increasing the pipe packing speed and lower the labor cost.

Only one operator required for operating the line.

Packing speed: upto 100m per minute.

https://www.fhopepack.com/Automatic-Steel-Tube-Packing-Line/

• The line is designed to automatically pack rectangular steel pipes into bundles for easier handling, storage and transport.

• Only one operator is required to load pipes into the line and discharge the finished bundles. All packing functions are automated.

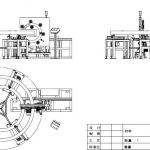

• Components of the line likely include:

- A pipe infeeding system that queues pipes and feeds them into the line at a controlled rate

- A wrapping unit that applies stretch film around sequential pipes to form a bundle

- An adjustable mandrel or frame that the pipes are wrapped around

- A cutting mechanism to sever the film after each bundle is formed

- A discharge conveyor to remove the packed bundles

• A PLC control system coordinates the functions and speeds of each unit to achieve the target packing speed of up to 100 meters of pipe per minute.

• Depending on pipe dimensions, multiple wrapping heads may be used in parallel to achieve the high packing speeds.

• The packing mandrel or frames can be adjusted to match the width and height of different sized pipes, ensuring a snug film wrap for all bundles.

• Safety features like light curtains and guards cover moving parts to protect the single operator.

• Automating the packing process offers benefits like:

- Consistent bundles due to precise stretch film application

- Higher throughput compared to manual packing methods

- Less waste from automated film dispensing and cutting

• Proper maintenance of items like wrapping units, drive chains and rollers is needed to sustain the high packing speeds and ensure reliability.

So in summary, a rectangular steel pipe packing line can automate bundling of pipes using high-speed stretch film wrapping to produce consistent bundles at rates exceeding 100 meters per minute, while keeping operational and material costs low through minimizing manual labor.