Mastering PU Air Pipe Coiling: A Deep Dive into the Semi-Automatic Bobbin Winder

In modern manufacturing, efficiency, precision, and consistency are paramount. For industries relying on polyurethane (PU) air pipes – from automotive assembly lines to pneumatic tool operations – managing and preparing these hoses can be a significant operational bottleneck if done manually. The Semi-automatic PU Air Pipe Coiling Machine with Bobbin emerges as a critical solution, designed to streamline the coiling process, enhance product quality, and boost overall productivity. This article delves into the technical specifications, design philosophy, operational advantages, and real-world applications of this versatile equipment.

1. The Challenge: Inefficiencies in Manual PU Pipe Handling

Manually coiling PU air pipes, especially in large volumes, presents several challenges:

- Inconsistency: Achieving uniform coil diameter and length is difficult, leading to variations in final product presentation and potential issues in downstream processes.

- Labor Intensive: Manual coiling requires significant operator time and effort, increasing labor costs.

- Potential Damage: Improper handling can lead to kinks or damage to the PU pipe, affecting its performance and lifespan.

- Slow Throughput: Manual processes inherently limit the speed of production, impacting overall output.

Addressing these pain points requires a solution that blends automation with operator control – the niche perfectly filled by the semi-automatic coiling machine.

2. Introducing the Semi-Automatic PU Air Pipe Coiling Machine with Bobbin

This machine is specifically engineered to wind PU air pipes neatly onto bobbins. Its semi-automatic nature means the operator initiates the process and oversees operation, while the machine executes the precise, repetitive task of coiling. This approach offers a balance between the full automation's speed and the manual process's flexibility, making it ideal for varied production needs.

3. Technical Specifications & Data Deep Dive

Understanding the machine's capabilities requires a look at its core technical data. While exact specifications can vary by model, typical parameters include:

- Applicable Pipe Material: Polyurethane (PU), adaptable for similar flexible tubing.

- Pipe Diameter Range: Commonly accommodates ø4mm - ø16mm (customizable ranges available).

- Coiling Speed: Variable, typically 50 - 150 RPM (adjustable via VFD - Variable Frequency Drive).

- Maximum Coil Outer Diameter: Up to 400mm (dependent on bobbin size and machine configuration).

- Bobbin Compatibility:

- Inner Diameter (Bore): Adaptable, common sizes 50mm - 100mm.

- Outer Diameter: Up to 450mm.

- Width: Adjustable traverse for widths 50mm - 300mm.

- Length Measurement: High-precision digital counter (encoder-based), accuracy typically ±0.1%.

- Control System: PLC (Programmable Logic Controller) with HMI (Human-Machine Interface) touchscreen.

- Drive Motor: 0.75 kW - 2.2 kW AC Motor with VFD.

- Power Supply: 220V/380V, 50/60Hz, 3-Phase (configurable).

- Machine Dimensions (Approx.): 1500mm (L) x 1000mm (W) x 1200mm (H).

- Weight (Approx.): 300 - 500 kg.

Note: Specifications are indicative and may vary based on the specific model and customization requests.

4. Core Components & Engineering Design Philosophy

The machine's reliability and performance stem from its well-engineered components and thoughtful design:

- Robust Steel Frame: Constructed from heavy-gauge steel, often powder-coated for corrosion resistance. This ensures stability during operation, minimizes vibration, and guarantees longevity even in demanding industrial environments.

- Precision Drive System: Utilizes a combination of a reliable AC motor and a Variable Frequency Drive (VFD). This allows for smooth start/stop operations and precise control over coiling speed, crucial for handling different PU pipe stiffness and diameters without stretching or damaging the material.

- Intelligent Control Panel (HMI): Features a user-friendly touchscreen interface. Operators can easily set parameters like target length, coiling speed, pipe diameter, and bobbin dimensions. The PLC backbone ensures accurate execution of commands and stores presets for different products.

- Accurate Length Counter: An encoder integrated with a measuring wheel runs along the pipe, providing real-time length measurement displayed on the HMI. The system automatically stops the coiling process once the preset length is reached.

- Adjustable Bobbin Holder: Designed for quick and secure mounting/dismounting of various bobbin sizes. Often includes conical locks or expandable chucks for firm gripping.

- Traversing Unit: A synchronized mechanism that guides the pipe evenly across the bobbin width, ensuring a neat, layer-wound coil without overlaps or gaps. The traverse pitch is usually adjustable based on the pipe diameter.

- Safety Features: Equipped with emergency stop buttons, protective guards around moving parts, and often interlock systems that halt operation if guards are opened, complying with industrial safety standards.

The design prioritizes ease of use, reliability, accuracy, and operator safety.

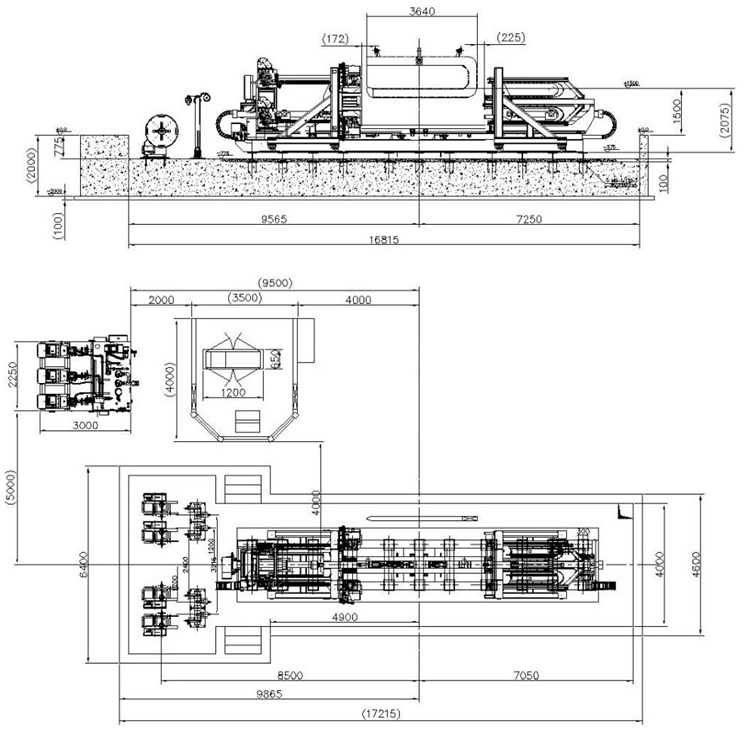

[Add Alt Text: Diagram illustrating the main parts of the PU air pipe coiling machine, including the drive, control panel, bobbin holder, and traversing unit.]

[Add Alt Text: Diagram illustrating the main parts of the PU air pipe coiling machine, including the drive, control panel, bobbin holder, and traversing unit.]

5. Operational Workflow & User Experience

Operating the semi-automatic coiler is designed to be straightforward:

- Setup: The operator mounts the appropriate bobbin onto the holder and secures it.

- Parameter Input: Using the HMI, the operator selects or inputs the required parameters: target pipe length, coiling speed, pipe diameter (for traverse pitch calculation), and bobbin dimensions.

- Pipe Loading: The leading end of the PU air pipe is manually fed through the measuring unit and secured to the bobbin core.

- Initiation: The operator starts the coiling cycle via the control panel.

- Automated Coiling: The machine automatically coils the pipe onto the bobbin at the set speed, with the traversing unit ensuring even layering. The digital counter monitors the length.

- Automatic Stop: Once the preset length is reached, the machine automatically stops.

- Finishing: The operator cuts the pipe, secures the end to the coil (often with tape or ties), and dismounts the finished bobbin.

- Repeat: The process is ready to be repeated for the next coil.

This workflow significantly reduces manual handling, minimizes errors, and allows a single operator to manage the process efficiently, freeing up time for other tasks. The intuitive interface reduces training time and enhances operator comfort.

6. Key Features & Advantages Explained

The features translate directly into tangible benefits for manufacturers:

- Semi-Automatic Operation: Offers the optimal blend of automation speed and manual flexibility for diverse production runs. Less costly than fully automatic systems but far more efficient than manual methods.

- Bobbin Compatibility: Versatility to handle various standard and custom bobbin sizes increases the machine's utility across different product lines and packaging requirements.

- Adjustable Coiling Speed: Allows fine-tuning for different PU pipe types (varying wall thickness, stiffness) ensuring optimal coiling quality without damaging the pipe.

- Precision Length Measurement: Guarantees accurate product lengths, reducing material waste and ensuring customer satisfaction. Critical for kitting and assembly applications.

- Enhanced Efficiency: Dramatically reduces the time and labor required per coil compared to manual methods, directly boosting output capacity.

- Improved Coil Quality: Produces consistently neat, tightly wound coils, improving product presentation and preventing tangling or damage during storage and transport.

- Compact & Robust Design: Space-efficient footprint fits easily into existing production layouts, while the durable construction ensures long-term reliability and minimal downtime.

- Operator Safety: Integrated safety mechanisms protect personnel during operation.

[Add Alt Text: High-quality PU air hose coil wound uniformly onto a bobbin by the semi-automatic coiling machine.]

[Add Alt Text: High-quality PU air hose coil wound uniformly onto a bobbin by the semi-automatic coiling machine.]

7. Applications Across Industries

The Semi-Automatic PU Air Pipe Coiling Machine finds application wherever PU hoses are manufactured or processed:

- Pneumatic Tooling: Preparing hoses for air tools (impact wrenches, nail guns, spray guns) in consistent lengths for retail packaging or industrial use.

- Automotive Manufacturing: Coiling air brake lines or pneumatic control hoses used in vehicle assembly, ensuring quality and consistency for safety-critical components.

- Industrial Automation: Providing precisely measured lengths of PU tubing for robotic systems, pneumatic circuits, and machinery.

- Medical Equipment: Certain types of flexible medical tubing can be coiled using specialized versions of these machines (requires adherence to specific hygiene/material standards).

- General Manufacturing: Any facility producing or using bulk PU air pipes that need to be processed into manageable, standardized lengths on bobbins.

8. Return on Investment (ROI) and Efficiency Gains

Investing in a semi-automatic coiling machine yields significant returns:

- Reduced Labor Costs: Lower reliance on manual labor translates directly to cost savings.

- Increased Throughput: Faster coiling cycles mean higher production output per shift.

- Minimized Material Waste: Accurate length control prevents over- or under-cutting, saving valuable PU material.

- Improved Product Quality & Consistency: Reduces rejects and enhances customer perception, potentially commanding better market positioning.

- Enhanced Operational Safety: Reduces risks associated with manual repetitive tasks.

The cumulative effect is a faster payback period and improved profitability for the production line.

9. Maintenance & Longevity

Designed for industrial use, these machines generally require minimal maintenance:

- Regular Cleaning: Keeping the machine free of dust and debris.

- Lubrication: Periodic lubrication of moving parts like bearings and guides as per the manufacturer's schedule.

- Inspection: Routine checks of belts, sensors, and safety features.

With proper care, the robust construction ensures a long operational lifespan, providing value for many years.

10. Conclusion: Elevating Your PU Pipe Production

The Semi-Automatic PU Air Pipe Coiling Machine with Bobbin is more than just a winding tool; it's a strategic asset for manufacturers seeking to optimize their operations. By integrating precise automation with necessary operator control, it addresses the core challenges of manual coiling, delivering significant improvements in efficiency, accuracy, quality, and safety. Its technical capabilities, robust design, and versatility make it an indispensable piece of equipment for any facility serious about producing or processing PU air pipes competitively in today's demanding market. Adopting this technology represents a clear step towards leaner, more reliable, and more profitable manufacturing.