Optimizing Large Bearing Packaging: A Technical Deep Dive into Fhope's Automated Wrapping Machine

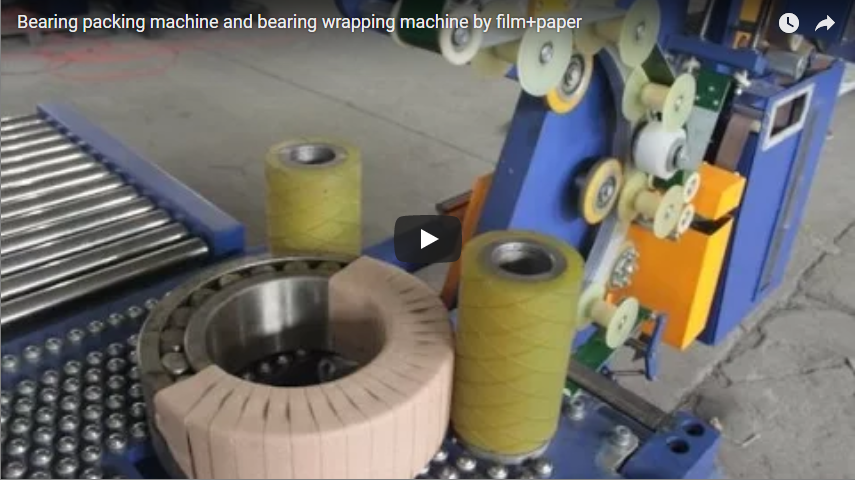

The efficient and safe packaging of large-diameter bearings presents significant challenges in industrial settings. Manual methods are often time-consuming, physically demanding, and can lead to inconsistent wrapping quality, potentially compromising bearing protection. Fhopepack offers automated solutions designed to address these issues, exemplified by their specialized large bearing packing machine. This article provides a technical overview of the machine's design, capabilities, and operational aspects, aligning with the detailed analysis expected by industry professionals.

1. Addressing the Challenges in Large Bearing Packaging

Manual packaging of heavy and unwieldy bearings (often exceeding several tonnes) poses inherent risks:

- Safety Hazards: Lifting and manipulating large bearings manually increases the risk of musculoskeletal injuries.

- Inconsistent Quality: Achieving uniform tension and overlap with wrapping materials manually is difficult, potentially leading to inadequate protection against corrosion and contaminants.

- Low Efficiency: Manual wrapping is labour-intensive and slow, creating bottlenecks in production or logistics workflows.

- Material Wastage: Inconsistent application can lead to excessive use of packaging materials like stretch film or VCI paper.

Automated wrapping machines, like the Fhope model showcased, directly counter these drawbacks by providing a controlled, repeatable, and efficient packaging process.

2. Fhope Large Bearing Wrapping Machine: Design & Structural Integrity

The machine is engineered for heavy-duty industrial environments, focusing on durability and operational reliability. Key structural and design elements include:

- Robust Frame Construction: Built with heavy-gauge steel to withstand the significant weight and dynamic forces involved in rotating and wrapping large bearings.

- Adjustable Support Roller System: Features multiple supportive rollers (typically 4 or more) coated with durable Polyurethane (PU). This coating prevents damage to the bearing surface during rotation. The rollers are adjustable to accommodate a wide range of bearing outer diameters (OD), starting from a specified minimum (e.g., 2000mm in the example provided).

- Rotating Ring & Wrapping Shuttle: A core component that carries the packaging material dispenser (shuttle) and rotates around the bearing, applying the film or paper circumferentially.

- Integrated Control System: Typically utilizes a Programmable Logic Controller (PLC) coupled with a Human-Machine Interface (HMI) touchscreen panel for parameter setting and operational control.

3. Key Technical Specifications & Capabilities

While specific configurations can be customized, typical performance parameters for the Fhope large bearing wrapping machine include:

- Bearing Outer Diameter (OD): Capable of handling bearings up to 6500mm (as per the video example), with adjustable rollers accommodating sizes from 2000mm upwards.

- Bearing Width: Accommodates bearing widths up to 600mm or potentially more, depending on the model.

- Load Capacity: Designed to support multi-tonne bearings safely.

- Support Roller Configuration: 4 x heavy-duty PU-coated rollers, adjustable positioning.

- Wrapping Materials: Compatible with various materials, including stretch film, VCI (Volatile Corrosion Inhibitor) paper, composite paper, and woven belts.

- Control System: PLC with Touchscreen HMI (provides storage for multiple packing recipes).

- Optional Features: Integrated oil injection system for applying protective coatings during the wrapping cycle.

Technical Data Comparison (Illustrative Example):

| Feature | Fhope Large Bearing Wrapper | Typical Manual Process |

|---|---|---|

| Max Bearing OD | Up to 6500 mm | Limited by handling |

| Max Bearing Width | Up to 600 mm | Limited by handling |

| Cycle Time | Significantly Reduced | Highly Variable, Slow |

| Consistency | High (Uniform Tension/Overlap) | Low to Medium |

| Operator Safety | High | Lower (Handling Risks) |

| Material Efficiency | Optimized | Potential for Waste |

| Labor Requirement | Low (Supervisory) | High |

| Oiling Integration | Available (Optional) | Separate Manual Step |

4. Core Components & Functionality Explained

- Support Roller System: Provides stable rotation for the bearing during wrapping. The adjustability allows the machine to center bearings of different diameters accurately relative to the wrapping ring. The PU coating ensures non-abrasive contact.

- Wrapping Ring & Shuttle: The ring's rotation speed and the shuttle's feed rate determine the wrapping overlap. Tension control mechanisms within the shuttle ensure the packaging material is applied tightly and consistently.

- Oiling System (Optional): An integrated nozzle system can spray or drip protective oil onto the bearing surfaces synchronously with the wrapping process, ensuring comprehensive corrosion protection beneath the packaging layer.

- Clamping & Cutting Unit: Automates the start and end of the wrapping cycle by securely clamping the leading edge of the material and automatically cutting it upon completion, minimizing manual intervention.

- Safety Features: Typically includes safety fencing, light curtains, emergency stop buttons, and interlocking access doors to ensure operator safety during operation.

5. Operational Workflow & User Experience

The HMI simplifies machine operation:

- Loading: The large bearing is typically loaded onto the support rollers using an overhead crane or forklift.

- Parameter Setting/Recall: The operator uses the touchscreen HMI. The system allows saving multiple parameter sets (e.g., 14 presets mentioned in the original description).

- Input Product Number: Recalls a pre-saved set of parameters (Bearing OD, ID, Width, desired overlap, material width, etc.).

- Manual Setting: Parameters can be entered or adjusted directly. Key settings include:

- Bearing dimensions (OD, ID, Width).

- Packaging material width (e.g., 40mm default).

- Desired overlap percentage or lap count.

- Clamper timing (e.g., 0.8s pull-back time).

- Rotation speed.

- Stop time/position.

- Initiate Cycle: Once parameters are confirmed, the operator starts the automated wrapping cycle.

- Wrapping Process: The machine automatically clamps the material, rotates the bearing via the support rollers, and orbits the wrapping shuttle around the bearing, applying the film/paper. The optional oiling system functions concurrently if enabled.

- Overlap Adjustment: If observation during the cycle (or post-wrapping inspection) indicates too much or too little overlap, operators can pause and adjust the "lap number correction" or similar parameters via the HMI (+/- seconds or percentage) for subsequent cycles or bearings.

- Cycle Completion & Cutting: The machine completes the programmed wraps, automatically cuts the material, and secures the tail end (depending on configuration).

- Unloading: The wrapped bearing is safely removed using appropriate lifting equipment.

The interface is designed to be intuitive, minimizing training time and allowing operators to manage different bearing sizes efficiently by recalling stored programs.

6. Benefits & ROI Considerations

Investing in an automated large bearing wrapping machine like Fhope's offers tangible benefits:

- Increased Throughput: Dramatically reduces packaging cycle times compared to manual methods.

- Enhanced Operator Safety: Minimizes direct manual handling of heavy components during the wrapping process.

- Consistent Packaging Quality: Ensures uniform material application and tension, providing reliable protection against environmental factors and corrosion (especially when combined with VCI materials or oiling).

- Reduced Material Waste: Precise control over overlap and tension optimizes the use of stretch film, VCI paper, or other materials.

- Labor Cost Savings: Reduces the number of personnel required for the packaging task and frees up labor for other value-added activities.

- Improved Product Presentation: Provides a professional, clean, and secure package.

The Return on Investment (ROI) is typically calculated based on savings in labor, material costs, reduced product damage/corrosion claims, and increased overall operational efficiency.

7. Customization & Alternative Solutions

Fhopepack recognizes that requirements vary. Customization options may include modifications to size capacity, integration with conveyor systems, specific safety features, or specialized material handling capabilities.

Furthermore, Fhope offers a range of bearing packing solutions tailored to different bearing sizes and types, as demonstrated by other available machinery configurations:

Conclusion

Automated wrapping machines, such as the Fhope large bearing packer, represent a significant advancement over manual packaging methods. By offering enhanced speed, safety, consistency, and material efficiency, these systems provide a robust solution for protecting valuable large-diameter bearings during storage and transit. The technical design, incorporating adjustable heavy-duty rollers, precise PLC control, and optional features like integrated oiling, addresses the specific challenges of handling oversized industrial components, making it a valuable asset for manufacturers and logistics providers in heavy industry.