Automated Coil Wrapping Solutions: Enhancing Efficiency for Hose and Pipe Packaging

Manually wrapping large, bulky coils of corrugated hose or plastic pipe is often a time-consuming, labor-intensive, and inconsistent process. It can lead to bottlenecks in production, increased labor costs, inefficient material usage, and potential damage to products during handling and transport. Automating this process with specialized machinery offers a significant competitive advantage. FHOPEPACK provides a range of automated hose coil wrapping machines designed to address these challenges head-on, delivering efficient, secure, and professional packaging solutions.

The Challenge: Inefficiencies in Manual Coil Packaging

Traditional methods of securing hose and pipe coils often involve manual strapping, banding, or shrink wrapping. These methods typically suffer from:

- High Labor Costs: Requiring dedicated personnel for a repetitive task.

- Inconsistent Wrap Quality: Varying tension and overlap can lead to loose or damaged packages.

- Material Waste: Difficulty in controlling the amount of film or wrapping material used.

- Low Throughput: Manual processes inherently limit packaging speed.

- Risk of Product Damage: Inadequate protection against environmental factors or handling stresses.

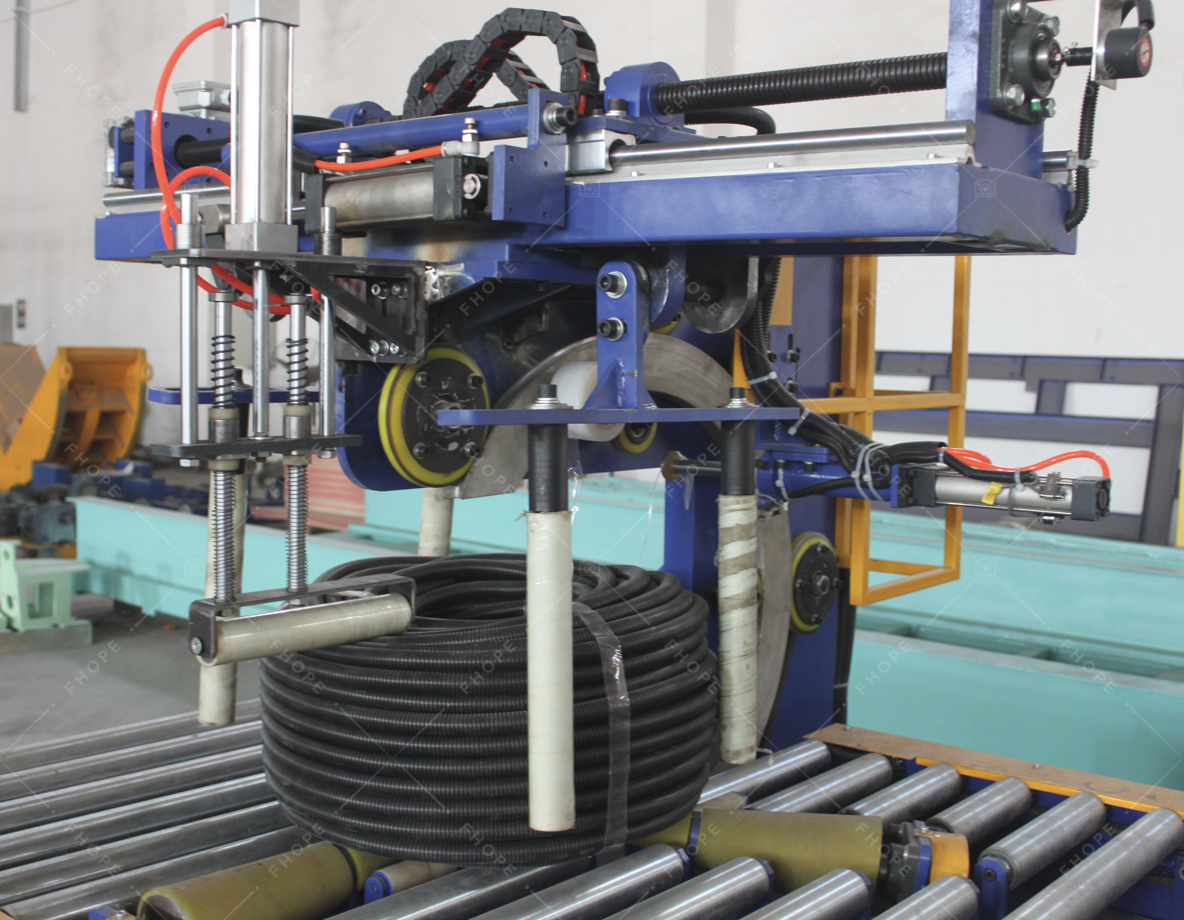

The Solution: FHOPEPACK Automated Orbital Wrapping Technology

FHOPEPACK specializes in orbital wrapping technology, where the wrapping material revolves around the stationary coil, ensuring a tight, consistent, and protective wrap. This approach is ideal for ring-shaped products like hose coils and pipes.

Machine in Action: Visualizing the Process

See the efficiency and precision of an automated hose coil wrapping machine in operation:

This video demonstrates the core wrapping cycle, highlighting the speed and uniformity achievable with automation.

Key Features and Technical Capabilities

FHOPEPACK's hose coil wrapping machines are engineered for performance and reliability. While specific models vary, typical technical features include:

-

Versatile Coil Handling:

- Inner Diameter (ID): Accommodates a wide range, adaptable to specific needs.

- Outer Diameter (OD): Capable of handling diverse coil sizes.

- Coil Width: Adjustable settings for different product widths.

-

Advanced Wrapping System:

- Wrapping Materials: Compatible with various films and materials, including PE film, LLDPE stretch film, HDPE woven fabric, and paper, allowing flexibility based on protection requirements and cost.

- Wrapping Speed: High-speed operation, capable of wrapping a coil in as little as 15-25 seconds (depending on coil size and wrap configuration).

- Overlap Control: Adjustable film overlap rate (typically 10%-90%) for customized package strength and material economy.

- Film Tension Control: Precise tension adjustment ensures package stability without damaging the product.

-

Automation and Control:

- PLC Control System: Reliable Programmable Logic Controller for managing machine functions.

- HMI Interface: User-friendly Human-Machine Interface for easy operation, parameter setting, and diagnostics.

- Automated Cycles: Options for automatic film feeding, clamping, cutting, and coil ejection to minimize manual intervention.

-

Robust Construction:

- Heavy-Duty Frame: Built for industrial environments and long service life.

- Safety Features: Equipped with safety guards, sensors, and emergency stops compliant with industry standards.

Tangible Benefits: Beyond Speed and Automation

Investing in an automated coil wrapping solution like those from FHOPEPACK delivers substantial operational advantages:

- Significant Labor Savings: Automating the wrapping process frees up personnel for higher-value tasks, directly reducing labor costs associated with packaging. User feedback often highlights the ability to reallocate one or more operators per shift.

- Reduced Material Consumption: Precise control over film stretch (pre-stretch capabilities often available) and overlap minimizes material waste compared to manual wrapping, leading to direct cost savings on consumables.

- Enhanced Product Protection: Uniform, tightly wrapped coils are better protected against dust, moisture, UV radiation, and damage during shipping and storage, reducing returns and quality complaints.

- Improved Package Appearance: Consistent, professional-looking packages enhance brand image and customer perception.

- Increased Throughput: Faster wrapping cycles directly translate to higher packaging capacity, keeping pace with production output and reducing bottlenecks.

- Versatility for Diverse Products: These systems are adaptable for various flexible pipe and hose types, including corrugated hoses, hydraulic hoses, garden hoses, HDPE pipes, PVC conduits, PEX tubing, and more.

Industry Applications and User Experience

FHOPEPACK wrapping machines are utilized across various sectors:

- Automotive: Wrapping hoses and wire harnesses.

- Construction & Plumbing: Packaging PEX, PVC, and HDPE pipes and conduits.

- Agriculture: Securing irrigation tubing and drainage pipes.

- Manufacturing: General industrial hose and tube packaging.

Companies adopting this technology typically report a rapid Return on Investment (ROI) driven by the combined savings in labor, materials, and reduced product damage. The reliability and ease of use of modern PLC-controlled systems further contribute to a positive operational experience.

Choosing the Right Wrapping Solution

FHOPEPACK offers solutions tailored to different production volumes, coil sizes, and automation requirements. Factors to consider when selecting a machine include:

- Coil dimension range (ID, OD, Width)

- Required throughput (coils per hour/day)

- Desired level of automation (feeding, cutting, ejection)

- Specific wrapping material requirements

- Integration needs with existing production lines

Consulting with packaging specialists can help determine the optimal configuration for your specific needs. For insights into packaging machinery standards and trends, resources like PMMI (The Association for Packaging and Processing Technologies) can be valuable.

Conclusion: Streamline Your Coil Packaging

Automated hose and pipe coil wrapping machines from FHOPEPACK represent a strategic investment for manufacturers seeking to improve efficiency, reduce costs, and enhance product protection. By leveraging proven orbital wrapping technology combined with robust engineering and user-friendly controls, these machines provide a reliable and effective solution to the challenges of manual packaging. The ability to handle diverse materials and coil sizes ensures flexibility, while the significant savings in labor and consumables contribute directly to the bottom line.

Explore the range of solutions available and discover how automated wrapping can transform your packaging operations.

For more details on specific machine capabilities and configurations, visit: https://www.fhopepack.com/Hose-packaging-machine/