Advanced VCI Stretch Wrapping System Protects Large Wind Turbine Bearings

The reliable operation of wind turbines hinges on the integrity of their critical components, particularly large-diameter bearings. These high-value assets face significant corrosion risks during extended storage periods and complex logistical journeys, often involving marine transport and exposure to fluctuating environmental conditions. Protecting these investments requires specialized packaging solutions. FHOPE offers an Automatic Bearing Packing Machine specifically engineered for large bearings, incorporating Volatile Corrosion Inhibitor (VCI) film technology and automated horizontal stretch wrapping.

The Critical Role of VCI Technology in Bearing Preservation

Large bearings, often manufactured from sophisticated steel alloys, are highly susceptible to corrosion. Moisture, salt, and atmospheric contaminants can initiate oxidation, leading to surface damage, reduced operational lifespan, and potentially catastrophic failure. VCI technology offers a proven defense mechanism.

- Mechanism of Action: VCI compounds embedded within the packaging film (typically polyethylene) vaporize, creating a protective molecular layer on the metal surfaces of the bearing. This invisible layer disrupts the electrochemical corrosion process. According to research published in journals like Corrosion Science and industry standards such as MIL-PRF-22019, VCI effectiveness depends on factors like emitter rate, barrier properties of the film, and the enclosed air volume.

- VCI Film Selection: The FHOPE system utilizes specialized VCI stretch film designed for ferrous metals. This film provides both a physical barrier against external contaminants and active chemical protection through VCI diffusion. The selection of appropriate VCI chemistry is crucial, considering the specific metal composition of the bearings being packaged.

Horizontal Stretch Wrapping: Optimized for Large Ring Structures

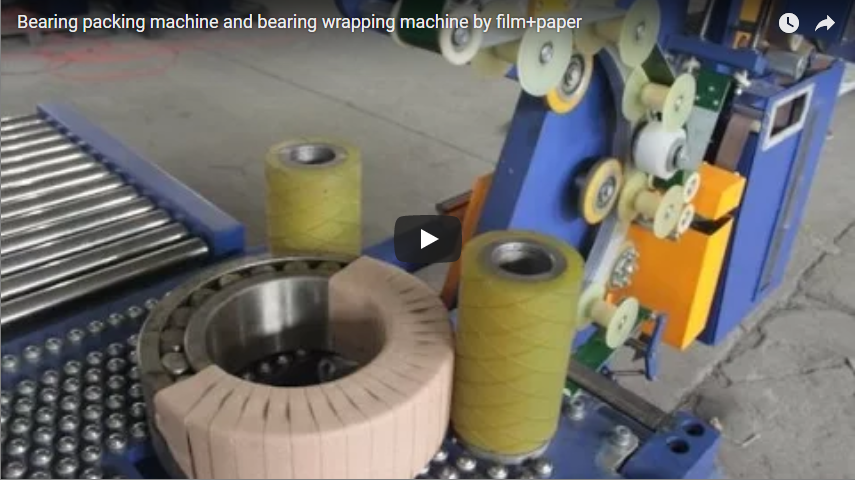

Packaging large, heavy, ring-shaped components like wind turbine bearings presents unique handling and wrapping challenges. The FHOPE machine employs a horizontal orbital stretch wrapping method, recognized for its efficiency and effectiveness in these applications.

- Process: The bearing is typically positioned on driven support rollers. A film carriage, holding the VCI stretch film roll, orbits horizontally through the eye of the bearing, dispensing the film and wrapping the entire circumference securely.

- Advantages: This method ensures consistent film application and tension control around the bearing's complex geometry (inner diameter, outer diameter, and faces). Unlike traditional pallet wrapping, horizontal wrapping fully encapsulates the product without needing a pallet base during the primary wrapping stage.

- Film Economy and Load Stability: The system incorporates powered pre-stretch capabilities (often achieving ratios up to 250-300%), significantly reducing film consumption while enhancing load containment force. This ensures the VCI film remains tightly secured, maximizing barrier properties and minimizing the risk of damage during handling.

System Design for Efficiency and Safety in Industrial Environments

Automating the packaging process for large bearings addresses key operational challenges related to manual labor, consistency, and safety.

- Automation & Throughput: The FHOPE machine streamlines the packaging workflow, reducing manual handling requirements and improving cycle times compared to manual or semi-automatic methods. Integration with upstream and downstream conveyor systems or robotic handling is often possible for fully automated lines.

- Handling Large Components: The machine's structure, including robust support rollers and frame, is designed to manage the significant weight and dimensions of wind power bearings (often exceeding several meters in diameter).

- Control and Precision: PLC controls with HMI interfaces allow operators to set wrapping parameters (e.g., film overlap, tension, rotation speed, pre-stretch ratio) ensuring repeatable and optimized packaging quality for different bearing sizes.

- Safety Integration: Adhering to industrial safety standards (e.g., ISO 13849-1), the machine incorporates safety fencing, light curtains, emergency stops, and interlocking access doors to protect personnel during operation.

Key Features and Technical Considerations

- Product Compatibility: Designed for large bearings (specify typical OD/ID range if available, e.g., 1000mm - 4000mm OD).

- Wrapping Material: Optimized for VCI stretch film; compatible with standard PE stretch films.

- Wrapping Method: Horizontal orbital stretch wrapping.

- Film Pre-Stretch: Powered system (specify typical % range, e.g., up to 300%).

- Control System: PLC with Touch Screen HMI.

- Construction: Heavy-duty steel frame.

- Safety: Compliant with relevant industrial safety regulations.

Conclusion: Ensuring Bearing Integrity from Factory to Field

The FHOPE Automatic Bearing Packing Machine provides a robust, automated solution for protecting large, high-value bearings, particularly those destined for the demanding wind energy sector. By combining the proven effectiveness of VCI corrosion inhibitors with the efficiency and security of horizontal stretch wrapping technology, this system helps manufacturers and logistics providers safeguard component integrity, reduce the risk of costly corrosion damage, and ensure bearings arrive at their destination in optimal condition. The focus on automation, efficiency, and safety aligns with modern manufacturing and packaging best practices.

For more detailed specifications and consultation on integrating this system into your operations, please contact FHOPE at info@fhopepack.com.