Bear Packing Machine: Advanced Automated Solutions for Optimal Protection

1. Advancements in Automated Bearing Packaging: Ensuring Protection and Operational Efficiency

The integrity and operational performance of industrial bearings are fundamental across a multitude of sectors, from automotive manufacturing to heavy industry. However, these precision-engineered components are exceptionally susceptible to degradation from environmental factors, primarily corrosion and contamination, alongside the risk of physical damage during handling and logistical transit. Consequently, effective packaging transcends mere logistics; it is an indispensable factor in preserving product quality, reliability, and ultimately, extending service life. This article examines the technical specifications, design considerations, key components, and operational advantages of specialized automated packaging systems, with a particular focus on orbital wrapping technology engineered specifically for bearings.

2. The Critical Need for Specialized Bearing Protection

Bearings, typically manufactured from high-carbon chromium steel or similar high-grade alloys, possess an inherent vulnerability to oxidation and corrosion. Exposure to humidity, fluctuating ambient temperatures, or aggressive atmospheric agents can initiate corrosive processes. Furthermore, particulate contaminants like dust, dirt, and ingress of moisture can severely compromise the integrity of lubricants, leading to accelerated wear and premature component failure. Physical impacts or excessive vibration during shipping and handling represent another significant risk, potentially causing false brinelling or other mechanical damage to raceways and rolling elements.

Traditional manual packaging approaches often fall short, lacking the consistency, material science application, and protective layering required to effectively mitigate these diverse risks. Industry analyses consistently reveal that inadequate packaging is a major contributor to pre-installation bearing damage, resulting in elevated warranty claims, operational downtime for end-users, and negative impacts on brand reputation. The strategic application of appropriate protective materials, such as Volatile Corrosion Inhibitor (VCI) films or papers integrated into the packaging layers, combined with consistent and controlled wrapping techniques, is therefore essential. As emphasized in technical literature, including journals like Tribology International, meticulous surface protection during storage and transport phases is a critical determinant in maximizing the potential service life of bearings.

3. Orbital Wrapping Technology: Precision Engineering for Bearing Packaging

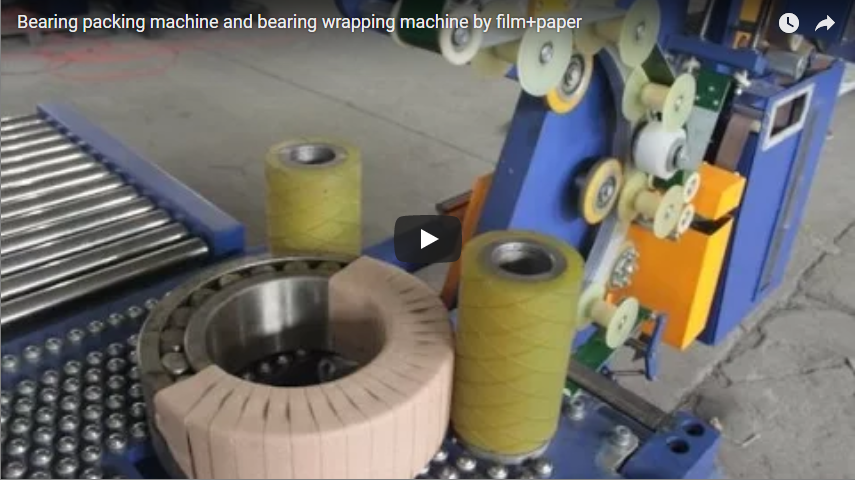

Automated packaging solutions, exemplified by the dedicated Bearing Packing Machine – a specialized iteration of coil packing machinery – directly address the aforementioned challenges through sophisticated precision engineering. The core technology typically employed is orbital wrapping. In this process, the packaging material (which can range from stretch film to VCI film or protective paper) is dispensed from a shuttle mechanism. This shuttle rotates orbitally, passing through the central bore of the bearing while the bearing itself is simultaneously rotated on a set of support rollers. This coordinated motion ensures comprehensive, tightly conforming coverage of all bearing surfaces, creating a sealed and protective barrier.

Key technological components and design features frequently include:

- PLC Control Systems: At the heart of the machine, Programmable Logic Controllers (PLCs) provide precise digital control over the entire wrapping sequence. This includes parameters such as ring and roller rotation speeds, the degree of packaging material overlap (critical for barrier integrity), and film/paper tension. Modern systems invariably feature Human-Machine Interfaces (HMIs), often touchscreens, providing intuitive operator control, recipe management, parameter adjustment, and diagnostic feedback.

- Advanced Film Tension Control: Maintaining optimal, consistent tension of the packaging material throughout the wrap cycle is crucial. Excessive tension could potentially damage sensitive bearing components, while insufficient tension compromises package stability and protective quality. Advanced machines incorporate sophisticated mechanisms, such as electromagnetic powder brakes on the film unwind or servo-driven pre-stretch units (for stretch film), to achieve and maintain precise tension control, adapting dynamically to the bearing geometry. Patents in packaging technology frequently highlight innovations aimed at achieving uniform tension distribution for superior load containment and optimized material usage.

- Integrated Material Handling Systems: For seamless integration into larger production or logistics workflows, these machines are often equipped with automated material handling components. This typically includes powered input and output conveyors, lifting/tilting mechanisms for ergonomic loading/unloading of heavy bearings, and automated centering devices. Sensors (e.g., photoelectric, laser, proximity) accurately detect bearing presence and dimensions, automatically initiating the correct wrapping cycle and ensuring precise positioning.

- Material Handling Versatility: Recognizing the diverse protection needs based on bearing type, storage duration, and transit conditions, these machines are engineered for flexibility. They can typically handle a broad spectrum of packaging materials:

- Stretch Film: Primarily Low-Density Polyethylene (LDPE) or Linear Low-Density Polyethylene (LLDPE) for containment and dust protection.

- VCI Film/Paper: Materials impregnated with Volatile Corrosion Inhibitors, conforming to international standards (e.g., MIL-PRF-22019, TRGS 615), providing active multi-metal corrosion protection.

- Barrier Materials: Crepe paper, compound paper, laminates (e.g., paper/poly), or woven fabrics for enhanced puncture resistance or specific barrier properties.

4. Key Performance Parameters and Operational Advantages

Modern automated bearing packing machines deliver tangible, quantifiable benefits and are defined by specific performance metrics essential for demanding industrial environments:

4.1 Technical Specifications (Typical Parameter Ranges - Model Dependent)

- Control System: PLC (e.g., Siemens, Allen-Bradley) with HMI Touchscreen Interface

- Applicable Wrapping Material: Stretch Film (LLDPE), VCI Film, VCI Crepe Paper, Compound Paper (Paper+PE), Woven Belt

- Bearing Outer Diameter (OD): 500mm - 2500mm (Consult specific model datasheet)

- Bearing Inner Diameter (ID): 300mm - 2000mm (Consult specific model datasheet)

- Bearing Width / Height: 50mm - 500mm (Consult specific model datasheet)

- Maximum Bearing Weight / Load Capacity: Up to 5000 kg (Consult specific model datasheet)

- Ring Rotation Speed: 1 - 4 m/min (Variable, PLC controlled)

- Wrapping Shuttle Speed: 40 - 90 RPM (Variable, PLC controlled)

- Packaging Material Overlap Rate: 10% - 90% (Adjustable via HMI/PLC)

- Film Pre-Stretch Ratio (if applicable): Up to 250% (Motorized pre-stretch)

- Standard Power Supply: 380V, 50Hz, 3-Phase (Customizable based on regional requirements)

- Compressed Air Requirement: 5-7 bar (For pneumatic actuators, if used)

4.2 Operational and Economic Benefits

- Superior Product Protection: The consistent, tightly applied layers achieved through automated orbital wrapping dramatically minimize the ingress of moisture and contaminants, significantly reducing the risk of corrosion and physical damage during transit and storage. The correct application of VCI materials offers reliable, long-term corrosion protection.

- Increased Throughput and Productivity: Automation vastly accelerates the packaging process compared to manual or semi-automated methods. Cycle times can often be reduced by 50-75% or more, depending on the bearing size and complexity of the wrap, directly boosting overall production line efficiency and output capacity.

- Reduced Labour Costs and Improved Ergonomics: Automated systems necessitate minimal operator intervention, typically limited to loading/unloading (if not fully automated) and material roll changes. This frees up valuable personnel for more complex, higher-value tasks and significantly reduces direct labor costs associated with manual packaging. It also improves workplace safety and ergonomics by minimizing manual handling of heavy components.

- Optimized Material Consumption: Precise PLC control over film tension, pre-stretch ratios (where applicable), and overlap percentages ensures efficient use of packaging materials. Compared to often inconsistent manual application, automated systems can yield substantial material savings, often reported in industry publications like Packaging Digest to be potentially up to 30% for stretch film, leading to direct cost reductions and a lower environmental footprint.

- Enhanced Workplace Safety: Modern machines are designed with safety as a priority, incorporating features like enclosed guarding around moving parts, safety interlocks on access doors, light curtains, and emergency stop systems, reducing operator exposure to potential hazards associated with moving machinery and heavy loads.

- Consistency and Quality Assurance: Automation eliminates the variability inherent in manual processes. Every bearing is packaged to the exact same pre-defined specifications, ensuring consistent quality, package appearance, and protection levels. This consistency enhances brand perception, reduces customer complaints, and strengthens overall quality assurance.

- Personal Experience Insights: Users migrating from manual to automated systems consistently report significant improvements in package integrity and a noticeable reduction in damage-related claims. The ease of setting parameters via the HMI for different bearing sizes allows for quick changeovers, enhancing operational flexibility. The reliability of the wrapping process also builds confidence in product delivery quality.

5. FHOPEPACK: Delivering Specialized Bearing Packaging Solutions

As a manufacturer possessing considerable expertise and a proven track record in industrial coil wrapping and automated packaging technology, FHOPEPACK offers robust solutions like the specialized Bearing Packing Machine. By integrating advanced engineering principles, utilizing high-quality, durable components, and focusing on user-friendly control systems, FHOPEPACK machines are meticulously designed to meet the stringent demands specific to the bearing industry. They provide tailored configurations capable of accommodating a wide spectrum of bearing dimensions (ID, OD, Width), weights, and diverse packaging material requirements, thereby ensuring clients achieve optimal product protection and enhanced operational efficiency within their manufacturing or distribution centers.

6. Conclusion: Strategic Investment in Bearing Integrity

In today's fiercely competitive global marketplace, safeguarding the pristine quality of high-precision components like industrial bearings through state-of-the-art packaging is not merely advantageous—it is a strategic imperative. Automated orbital wrapping machines represent a significant technological advancement over traditional manual methods, offering demonstrably superior protection against pervasive environmental threats (corrosion, contamination) and physical transit hazards. By integrating sophisticated features such as PLC-driven precision control, dynamic tension management systems, seamless material handling integration, and compatibility with advanced protective materials like VCI films, these systems deliver substantial, measurable improvements in packaging efficiency, operational cost-effectiveness, and ultimate product reliability. Investing in dedicated, automated bearing packing technology is, therefore, a prudent strategic decision for any company committed to optimizing its supply chain, minimizing waste, reducing quality-related costs, and upholding the highest standards of product integrity from the point of manufacture to the point of use.