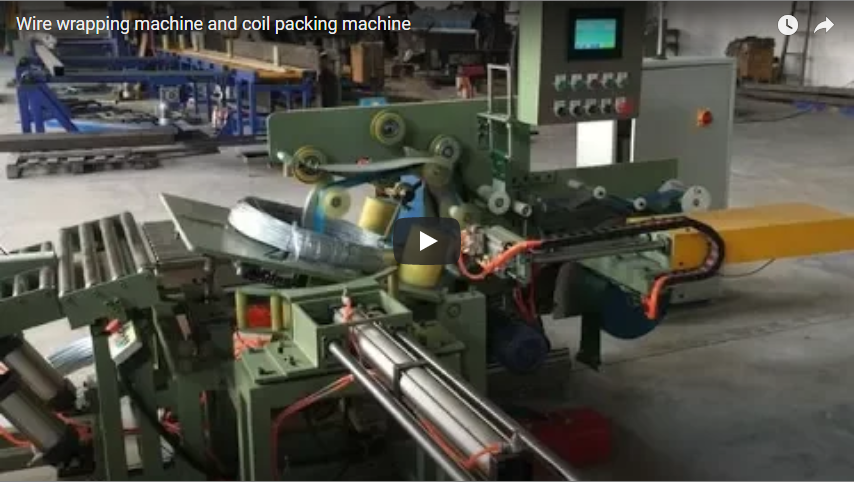

Automating the packaging of steel wire is crucial for enhancing efficiency, ensuring consistency, and improving safety in demanding industrial environments like metal fabrication and wire manufacturing. The automatic wire packing machine represents a significant technological advancement over manual or semi-automatic methods, streamlining the process from bulk wire to neatly packaged coils ready for storage or shipment. This article delves into the technical aspects, operational benefits, and application scope of this essential equipment, reflecting the practical focus valued by readers of The Fabricator.

1. The Shift from Manual Labor to Automated Precision

Traditional wire handling often involves labor-intensive processes that are prone to inconsistencies, potential safety hazards (e.g., repetitive strain injuries, cuts), and inefficiencies. Manual coiling can result in uneven coil sizes and densities, leading to challenges in storage, transport, and subsequent processing. Automatic wire packing machines directly address these limitations by introducing precision, speed, and repeatability into the packaging workflow.

2. Anatomy of an Automatic Wire Packing Machine: Key Components and Design

Understanding the core components provides insight into the machine's capabilities:

- Payoff System: Securely holds the bulk wire spool or carrier, providing controlled unwinding tension to prevent tangles and ensure smooth feeding. Designs vary based on the input wire format (spools, stems, loose coils).

- Wire Accumulator/Dancer: Maintains consistent wire tension and buffers speed differences between the payoff and the coiling head, preventing jerking or slack which can affect coil quality.

- Straightening Unit (Optional): For certain wire types or applications, rollers may be used to remove residual cast or curvature before coiling.

- Measuring Device: Precisely measures the length of wire fed into the coil, typically using calibrated wheels or laser sensors, ensuring consistent coil weight or length as per programmed parameters.

- Coiling Head/Mandrel: The core mechanism where the wire is wound into a coil. Designs can vary (e.g., collapsible mandrel for easy coil removal) and are often adjustable to accommodate different inner coil diameters.

- Cutting System: An automated mechanism (shear, blade) that cleanly cuts the wire once the desired length is reached. Precision cutting minimizes waste and ensures a neat coil end.

- Coil Transfer Mechanism: Transports the finished coil from the coiling head to the wrapping/strapping station. This can involve robotic arms, conveyors, or pusher systems.

- Wrapping/Strapping Station: Applies protective packaging material. Common options include:

- Stretch Film Wrapping: Encapsulates the coil tightly in stretch film, providing protection against moisture, dust, and unraveling.

- Strapping: Applies plastic (PP, PET) or steel straps around the coil circumference at multiple points for secure bundling.

- Paper Wrapping (e.g., VCI): Incorporates VCI (Vapor Corrosion Inhibitor) paper for enhanced rust protection, particularly crucial for steel wire.

- Control System (PLC & HMI): The brain of the machine, typically a Programmable Logic Controller (PLC) coupled with a Human-Machine Interface (HMI) touchscreen. This allows operators to set parameters (coil length/weight, diameter, wrapping cycles, strapping positions), monitor the process, and diagnose issues.

steel wire coil packing 3. Operational Workflow: A Step-by-Step Breakdown

The automated process generally follows these steps:

- Wire Feeding: Wire is drawn from the payoff stand through the accumulator and any straightening units.

- Measurement & Coiling: The wire passes through the measuring device and is wound onto the coiling head until the preset length or weight is achieved.

- Cutting: The feed stops, and the cutting mechanism severs the wire.

- Coil Ejection/Transfer: The coiling mandrel collapses or retracts, and the finished coil is transferred to the packaging station.

- Packaging: The wrapping and/or strapping units apply the selected protective materials according to programmed settings.

- Discharge: The fully packaged coil is ejected onto a conveyor, pallet, or collection area, ready for handling.

4. Key Technical Specifications Overview

While specific configurations vary, typical parameters provide a baseline understanding:

- Machine Type: Fully Automatic Steel Wire Coiling and Wrapping Line

- Wire Diameter Range: Commonly handles diameters from ~0.5mm up to 20mm or more, depending on machine model and configuration.

- Coiling Speed: Variable, often reaching up to 20-30 meters per minute feed speed, translating to several coils per minute depending on coil size.

- Maximum Coil Outer Diameter (OD): Typically adjustable, ranging up to 800mm or larger for heavy-duty models.

- Coil Inner Diameter (ID): Adjustable via mandrel settings, e.g., 300mm - 500mm.

- Maximum Coil Weight: Dependent on wire diameter and coil dimensions, can range from a few kilograms to over 1000kg.

- Compatible Wrapping Materials: Stretch film (LLDPE), High-Density Polyethylene (HDPE), VCI paper, crepe paper, woven belts.

- Strapping Options: PP or PET strapping compatibility.

- Control System: PLC (e.g., Siemens, Allen-Bradley) with touchscreen HMI for parameter input, diagnostics, and operational status display.

- Power Requirements: Typically 380V/415V, 50/60Hz, 3-Phase (specifics vary).

- Safety Features: Interlocked guarding around moving parts, emergency stop circuits, light curtains, fault detection systems.

- Tension Control: Advanced systems (e.g., servo-driven payoff, dancer arm feedback) for precise wire tension management during coiling.

- Approximate Machine Weight: Varies widely based on configuration, often 1500kg - 5000kg+.

- Estimated Footprint: Requires significant floor space, e.g., 4000mm x 3000mm up to larger footprints for integrated lines.

Note: The technical specifications listed provide a general overview. Specific machine configurations are tailored to application requirements. Please contact us for precise details matching your operational needs.

5. Tangible Advantages for Fabricators and Manufacturers

Investing in an automatic wire packing machine delivers significant operational benefits:

- Increased Throughput: Consistent, high-speed operation surpasses manual capabilities, boosting overall production output.

- Reduced Labor Costs: Automation minimizes the need for manual handling during coiling and wrapping, freeing up personnel for higher-value tasks.

- Enhanced Operator Safety: Enclosed designs and automated handling reduce exposure to moving parts and sharp wire ends.

- Improved Coil Quality & Consistency: Precise length measurement and controlled winding produce uniform coils, simplifying inventory management, storage, and downstream processing.

- Optimized Material Usage: Accurate wrapping and cutting minimize waste of both wire and packaging materials.

- Better Product Protection: Secure wrapping shields the wire from environmental factors (dust, moisture) and handling damage during transit.

- Streamlined Logistics: Uniformly sized and packaged coils are easier to stack, palletize, and transport.

6. Diverse Applications Across Industries

The utility of automatic wire packing machines extends across various sectors:

- Steel Wire Manufacturing: Essential for primary producers packaging various grades of steel wire (e.g., galvanized, annealed, PC strand) for sale to distributors or end-users. Ensures product quality and handling efficiency from the source.

- Construction Sector: Packaging reinforcement wire, rebar tie wire, or binding wire into manageable, site-ready coils. Reduces handling time on construction sites and minimizes material loss.

- Automotive & Appliance Manufacturing: Preparing wire used in components like springs, fasteners, or wiring harnesses. Consistent coiling aids automated feeding into subsequent production machinery.

- Cable and Wire Rope Production: Intermediate coiling steps or final packaging of finished wire rope or electrical cables (where applicable).

- Fencing and Mesh Production: Efficiently coiling wire feedstock used in weaving or welding fencing and mesh products.

- Metal Recycling Operations: Processing and packaging salvaged steel wire into dense, marketable coils, improving handling efficiency and maximizing resale value.

7. Operational Considerations: A User's Perspective

While highly efficient, successful implementation involves practical considerations:

- Ease of Use: Modern machines feature intuitive HMI interfaces for parameter setup and operation, but operator training is crucial for optimal use and troubleshooting.

- Maintenance: Requires regular preventative maintenance, including lubrication, sensor checks, blade sharpening/replacement, and inspection of belts and rollers. Access for maintenance should be considered during installation planning.

- Integration: Can often be integrated with upstream (drawing lines) and downstream (palletizing robots, warehouse management systems) equipment for fully automated production flow. Compatibility needs careful planning.

- Flexibility: Assess the machine's ability to handle the required range of wire diameters, coil sizes, and packaging materials. Changeover time between different specifications is also a factor.

8. Selecting the Right Automatic Wire Packing Solution

Choosing the appropriate machine involves evaluating several factors:

- Wire Specifications: Define the full range of wire diameters, types (mild steel, high carbon, stainless), and tempers to be processed.

- Coil Parameters: Determine the required inner/outer diameters, maximum weight, and required packaging (film wrap, strapping, paper).

- Throughput Needs: Calculate the required coiling speed and number of coils per hour/shift to meet production demands.

- Available Space: Consider the machine's footprint, including necessary clearance for operation, maintenance, and material flow.

- Budget: Balance initial investment cost against long-term savings in labor, efficiency gains, and material usage.

- Vendor Support: Evaluate the manufacturer's reputation, technical support availability, spare parts access, and training services.

Conclusion: Investing in Efficiency and Quality

The automatic wire packing machine is more than just a piece of equipment; it's a strategic investment for any operation handling significant volumes of steel wire. By automating the coiling and packaging process, businesses can achieve substantial improvements in productivity, safety, consistency, and overall cost-effectiveness. Aligning the machine's capabilities with specific operational needs ensures that fabricators and manufacturers can optimize their wire handling processes, maintain product integrity, and stay competitive in a demanding market.

For further information or to discuss specific application requirements:

Website: www.fhopepack.com

Email: info@fhopepack.com