Revolutionizing PPGI Coil Handling: Inside Advanced Automated Packaging Line Technology

The manufacturing landscape for Pre-Painted Galvanized Iron (PPGI) steel coils demands not only high production efficiency but also meticulous handling and packaging protocols to preserve surface integrity and prevent damage during transit and storage. Traditional manual or semi-automated packaging methods often fall short, introducing risks of inconsistencies, lower throughput, and potential safety hazards. Addressing these challenges head-on requires sophisticated automation, as exemplified by modern integrated packaging lines.

Addressing Key Challenges in PPGI Coil Packaging

Handling PPGI coils presents unique difficulties:

- Surface Sensitivity: The pre-painted surface is susceptible to scratches, abrasions, and contamination, necessitating non-marring contact surfaces and precise wrapping techniques.

- Corrosion Prevention: Exposure to moisture and environmental contaminants can compromise both the coating and the underlying steel. Effective barrier packaging is crucial.

- Handling Heavy Loads: The weight and dimensions of steel coils demand robust and reliable automated handling systems to ensure operational safety and efficiency.

- Throughput Demands: High-volume production requires packaging solutions that can keep pace without becoming a bottleneck.

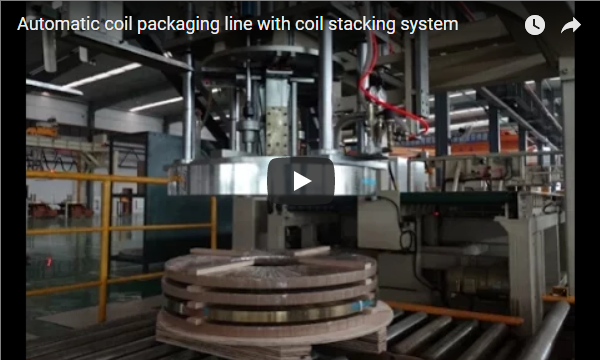

System Overview: An Integrated Approach to Coil Protection

The FHOPE Automatic Coil Packaging Line represents a comprehensive solution engineered specifically for the PPGI steel coil sector. By integrating multiple automated processes, this system streamlines the workflow from coil finishing to final dispatch, enhancing both product protection and operational metrics. Recent advancements in automation, often reflected in patent filings focusing on sensor integration and robotic precision (e.g., USPTO Class B65B), underscore the industry's shift towards fully integrated systems.

Key Components and Technological Advancements

This automated line incorporates several specialized modules, each contributing to a secure and efficient packaging cycle:

Automated Coil Transfer and Preparation

- Coil Car for Coil Transfer: Facilitates the smooth, automated movement of heavy coils from production or storage areas to the packaging line. Modern systems often incorporate laser guidance or rail systems for precise positioning, minimizing manual intervention and potential coil damage, a principle highlighted in material handling research papers focusing on AGV integration in heavy industries.

- Key Feature: Automated loading/unloading sequences synchronized with line operations.

Advanced Strapping Systems

- Coil Strapping Machine (Circumferential & Radial): Applies high-tensile strapping (typically PET or steel) both around the circumference and through the eye of the coil. This dual-strapping approach secures the coil windings and prepares it for subsequent wrapping.

- Technical Note: Precision tension control mechanisms, often utilizing servo drives, ensure consistent strap tension without damaging the coil edges – a critical factor for maintaining coil geometry, as noted in packaging engineering journals. Strapping heads are designed for high cycle speeds, significantly reducing processing time compared to manual methods.

Multi-Layer Protective Wrapping

- Paper Sheet Packing Machine: Applies VCI (Volatile Corrosion Inhibitor) paper or other protective liners directly onto the coil surfaces. This acts as a primary barrier against humidity and corrosive elements.

- Steel Sheet Covering: Adds a robust outer layer using steel sheets or similar durable materials, providing significant physical protection against impacts and environmental factors during transportation and storage. Research published in materials science forums often validates the effectiveness of multi-layer barrier systems for coated metals.

- Manual Corner Protection (Integrated Step): While largely automated, dedicated stations or protocols for applying reinforced corner protection address a common vulnerability point, preventing edge damage and deformation.

Flexible Packing Options & Finalization

- Manually Coil Bag Packing Option: Provides flexibility for specific customer requirements or non-standard coil sizes where a fully automated bagging solution might not be optimal. This ensures adaptability within the automated workflow.

- Coil Unloading System: Safely and efficiently transfers the fully packaged coils from the line to designated outbound logistics areas (e.g., conveyor systems, AGVs, or forklift pick-up zones). Integration with plant-level MES (Manufacturing Execution Systems) or WMS (Warehouse Management Systems) allows for real-time tracking and inventory management, a trend emphasized in IndustryWeek and Logistics Management publications.

Performance Benchmarks and Operational Gains

Implementing such automated packaging lines typically yields significant measurable benefits:

- Enhanced Throughput: Automation dramatically reduces cycle times per coil compared to manual or semi-automatic processes. Industry benchmarks often show potential throughput increases exceeding 50%.

- Improved Product Integrity: Consistent application of protective materials and strapping minimizes transit-related damages, leading to reduced claims and higher customer satisfaction. Studies often cite a reduction in damage rates by over 70% with optimized automated packaging.

- Increased Safety: Automating the handling of heavy coils and strapping operations significantly reduces ergonomic risks and potential accidents associated with manual labor, aligning with OSHA and ISO 45001 safety standards.

- Labor Optimization: Skilled workers can be redeployed from repetitive manual packaging tasks to more value-added roles like quality control and system monitoring.

- Material Efficiency: Automated systems apply materials like strapping and wrapping film with greater precision, potentially reducing material consumption and waste.

Conclusion: Investing in Future-Proof Coil Packaging

The transition towards fully automated packaging lines is becoming imperative in the competitive PPGI steel coil market. Systems like the FHOPE Automatic Coil Packaging Line offer a technologically advanced approach, integrating robust handling, precise strapping, and multi-layered protective wrapping. By addressing key challenges related to surface protection, operational efficiency, and safety, these integrated solutions provide a tangible return on investment through reduced damages, optimized labor, higher throughput, and enhanced product quality, ensuring manufacturers remain competitive and meet evolving customer expectations. The focus on integration, data exchange (IIoT readiness), and material science in packaging continues to drive innovation in this critical manufacturing segment.