Automated Paper Wrapping: Enhancing Protection and Efficiency for Aluminum Profiles

Aluminum extrusions, particularly those with cosmetic or high-tolerance surfaces, are susceptible to damage during handling, storage, and transit. Scratches, abrasions, and environmental factors can compromise product quality and lead to costly rework or rejection. Addressing this challenge requires robust and efficient packaging solutions. Automated paper wrapping systems offer a specialized approach to protect these valuable profiles.

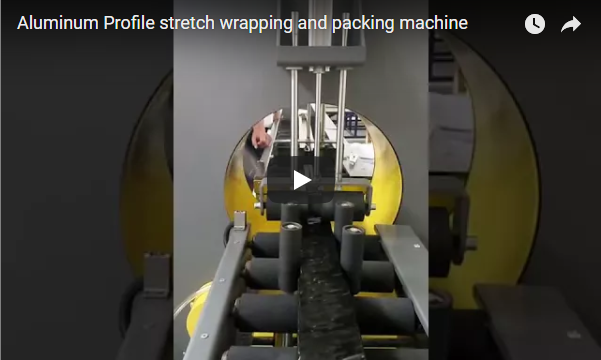

The automatic aluminum profile packing machine, often integrated into a larger packing line, is specifically engineered to provide an efficient, online protective wrapping solution primarily using paper-based materials. This equipment automates critical packaging steps, moving beyond basic bundling to offer superior surface protection.

1. The Core Challenge: Safeguarding Aluminum Extrusions

Aluminum profiles, used in applications ranging from architectural elements to industrial components, often feature delicate surface finishes. The primary goal of packaging is to preserve this finish. Key challenges include:

- Scratching and Abrasion: Contact with other profiles, handling equipment, or contaminants during transit can cause surface damage.

- Environmental Factors: Dust, moisture, and contaminants can affect the surface appearance and integrity.

- Handling Efficiency: Manual wrapping is labor-intensive, slow, and can lead to inconsistent application quality.

2. Automated Paper Wrapping Technology Explained

This type of machinery is designed to precisely apply a layer of protective paper (such as Kraft paper or VCI paper) around individual or grouped aluminum profiles. Unlike simple banding or strapping, paper wrapping provides comprehensive surface coverage, acting as a barrier against physical and environmental damage. The system typically integrates seamlessly into a production or finishing line.

3. Key Features and Technical Specifications

While specific configurations are often customized, typical features and specifications of an automated aluminum profile paper wrapping machine include:

- Profile Handling: Designed to accommodate various profile shapes and sizes (e.g., width up to 250mm, height up to 200mm, length up to 6-7 meters or more).

- Wrapping Material: Optimized for paper rolls (Kraft, VCI, potentially crepe paper) but may also handle complementary materials like stretch film depending on the model. Roll specifications (width, diameter, core size) are key parameters.

- Wrapping Mechanism: Often employs a rotating ring or orbital system to apply the paper spirally around the profile as it conveys through the machine.

- Automation Level: Fully automated operation with profile detection sensors, automatic paper feeding, wrapping, cutting, and sealing.

- Control System: PLC (Programmable Logic Controller) with an HMI (Human-Machine Interface) touchscreen for parameter setting (wrap overlap, speed, tension), diagnostics, and operational control.

- Wrapping Speed: Adjustable speeds, often ranging from 10 to 30 meters per minute, depending on profile size and wrapping requirements.

- Integration: Designed for integration with existing conveyors, cutting lines, stacking, and bundling systems.

Note: Specifications are indicative and highly customizable based on specific application requirements and profile characteristics.

4. Operational Workflow: From Extrusion to Wrapped Bundle

A typical operational sequence involves:

- Infeed: Profiles are fed onto the machine's conveyor system, often automatically from an upstream process.

- Detection: Sensors detect the leading edge of the profile, initiating the wrapping cycle.

- Wrapping: The wrapping head (e.g., rotating ring) dispenses and applies the paper spirally around the profile with controlled overlap and tension.

- Conveying: The profile moves continuously through the wrapping zone at a synchronized speed.

- Cutting and Sealing: Once the trailing edge of the profile is detected (or after a set length), the paper is automatically cut and secured (e.g., via heat sealing, adhesive tape, or tucking).

- Outfeed: The fully wrapped profile exits the machine onto an outfeed conveyor, ready for bundling, strapping, or the next handling stage.

5. Benefits of Automated Paper Wrapping

Implementing an automated paper wrapping system delivers significant advantages:

- Superior Surface Protection: Continuous paper coverage minimizes contact damage and shields against dust and minor impacts. VCI paper options add corrosion protection.

- Increased Throughput: Automation dramatically increases packaging speed compared to manual methods, reducing bottlenecks and boosting overall line efficiency.

- Reduced Labor Costs: Frees up personnel previously dedicated to manual wrapping, allowing them to focus on higher-value tasks. Improves workplace safety by automating repetitive motions.

- Material Efficiency: Precise control over wrap overlap and tension optimizes paper consumption compared to inconsistent manual application. Paper is often a recyclable and more sustainable option than plastic films.

- Consistent Quality: Ensures every profile receives the same level of protection with uniform wrap application, enhancing product quality and customer satisfaction.

- Flexibility: Systems can often be adjusted for different profile dimensions and wrapping requirements through the HMI.

6. Integrating the System: A Production Perspective

From a production standpoint, integrating such a machine requires careful planning:

- Line Layout: Consider the machine's footprint and its placement relative to upstream (e.g., extrusion press, cooling table, saw) and downstream (e.g., bundling, stacking, strapping) equipment.

- Material Handling: Ensure smooth and synchronized transfer of profiles into and out of the wrapping machine using appropriate conveyor systems.

- Customization: Work closely with the equipment provider to tailor the machine's specifications (size capacity, speed, wrapping materials) to match specific production needs.

- Maintenance: Incorporate the wrapper into the plant's preventive maintenance schedule, focusing on wear parts like cutters, rollers, and drive components.

7. Conclusion: A Strategic Investment in Quality and Efficiency

Automated aluminum profile paper packing machines represent a strategic investment for manufacturers seeking to enhance product protection, streamline operations, and reduce costs. By providing consistent, high-speed, and effective surface wrapping, these systems help ensure that aluminum extrusions reach their destination in optimal condition, safeguarding product value and brand reputation. They transition packaging from a necessary chore to an automated, value-adding step in the production process.

For detailed specifications or to discuss your specific aluminum profile packaging needs, please contact us.

info@fhopepack.com

Explore more aluminum packaging solutions:

https://www.fhopepack.com/Aluminum/