Boosting Protection and Efficiency: A Deep Dive into Orbital Bubble Film Wrappers for Doors and Panels

Protecting large, flat, and often fragile products like doors, panels, windows, and sheet materials during transit and storage is a critical challenge in manufacturing and fabrication. Damage incurred during these stages can lead to significant costs, customer dissatisfaction, and operational disruptions. Addressing this challenge requires robust and efficient packaging solutions. The orbital stretch wrapper, specifically configured for applying bubble film, represents a significant advancement in protective packaging technology, offering superior cushioning and containment compared to traditional methods.

Drawing inspiration from advancements documented in packaging technology patents (e.g., patents related to rotating ring stretch wrappers like US Patent 4,514,956 which outlined early concepts, later refined for specific film types and automation) and industry best practices highlighted in trade publications, these machines automate a previously labor-intensive process, ensuring consistency and reliability.

Understanding the Orbital Bubble Film Wrapping Process

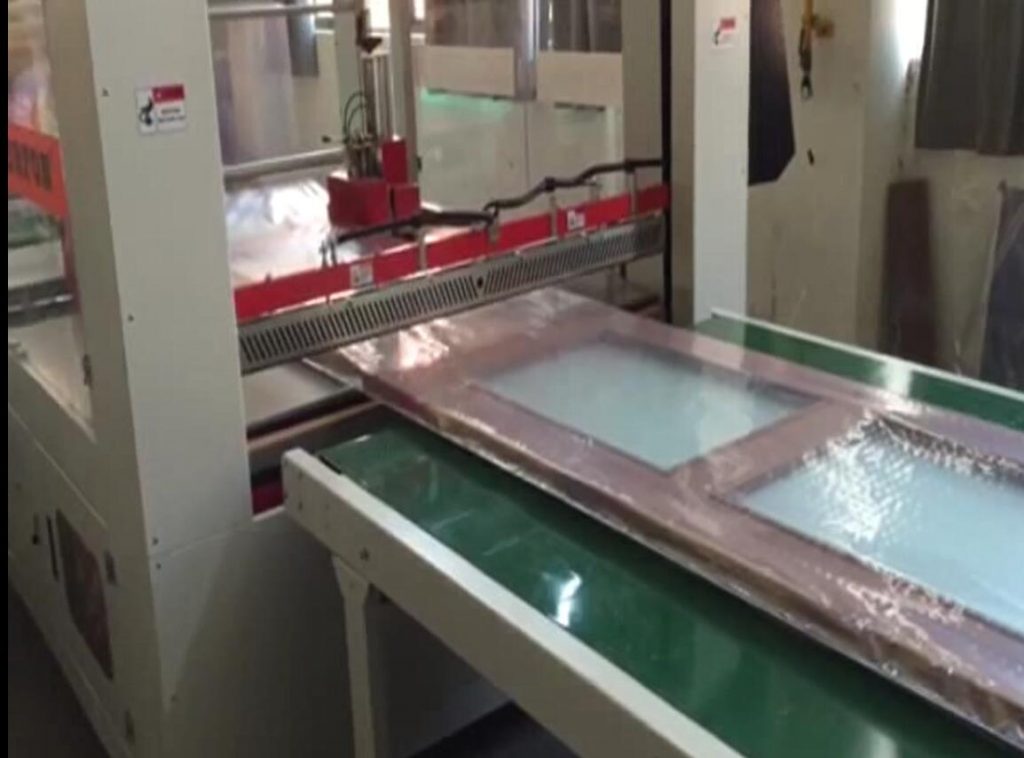

An orbital wrapper operates on a distinct principle compared to turntable or rotary arm stretch wrappers. The product remains stationary, typically moving horizontally on a conveyor, while a ring carrying the bubble film roll travels around the product profile. This makes it exceptionally suited for long, bulky, or unstable items that are difficult to rotate.

The core operational sequence, integrating automation and precision control systems often discussed in packaging engineering research, involves several key stages:

-

Product Infeed and Detection: Doors or panels are fed into the machine via an automated conveyor system. Sensors, often photoelectric eyes integrated with a Programmable Logic Controller (PLC), detect the product's leading and trailing edges. Advanced systems may incorporate sensors to measure product dimensions (length, width, height) automatically, optimizing the wrapping cycle and film usage based on pre-programmed parameters.

-

Initiation of Wrapping Cycle: As the product enters the wrapping zone, the PLC signals the ring mechanism to begin rotation. Simultaneously, the bubble film dispensing unit, mounted on the ring, activates. A clamp mechanism secures the leading edge of the bubble film to the product or conveyor temporarily.

-

Orbital Wrapping with Bubble Film: The ring rotates around the stationary or slowly conveying product, dispensing the bubble film. The key differentiator here is the use of bubble film, selected for its superior cushioning properties as analyzed in material science studies focusing on impact absorption. The film carriage often includes tension control mechanisms, and potentially pre-stretch capabilities (though less common with bubble film than traditional stretch film), ensuring the film conforms snugly without crushing the product's edges or damaging sensitive surfaces like glass inserts. The speed of the ring rotation and the conveyor movement are precisely synchronized to achieve the desired overlap and wrap density.

-

Film Severing and Sealing: Once the product is fully wrapped, sensors detect the trailing edge. The PLC initiates the cutting and sealing sequence. Typically, a heated bar or wire quickly cuts the bubble film and simultaneously seals the trailing edge to the previously applied layer, creating a secure, continuous protective cocoon around the product. This automated sealing mechanism, refined through ongoing engineering efforts often seen in patent filings for packaging machinery enhancements, ensures the wrap remains intact during subsequent handling.

-

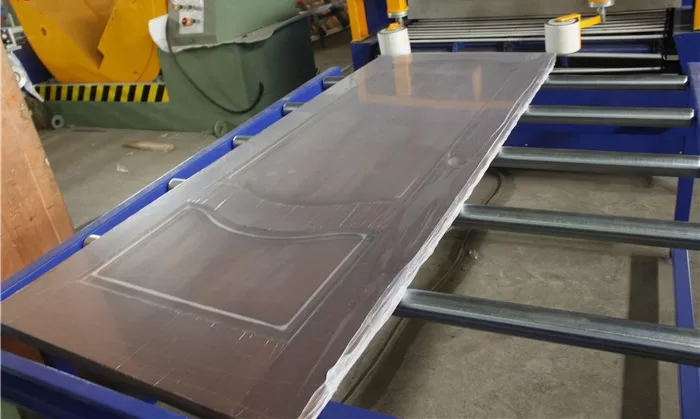

Product Outfeed: The fully wrapped door or panel continues along the conveyor system, exiting the machine. It is now ready for further processing, such as labeling, strapping (if required for bundling), palletizing, or direct loading for shipment.

Key Features and Technical Considerations

Modern orbital bubble film wrappers incorporate features derived from extensive R&D and aligned with industry demands for efficiency and reliability:

- Variable Ring Speed: Allows adjustment based on product fragility and desired throughput (typically ranging from 30 to 90 RPM).

- Adjustable Conveyor Speed: Enables synchronization with production line speed and control over wrap overlap.

- Automated Film Management: Includes features like automatic film clamping, cutting, and wiping/sealing units.

- Bubble Film Compatibility: Designed to handle standard bubble film roll widths, diameters, and core sizes. Specific considerations may apply for different bubble sizes or film thicknesses.

- PLC Control with HMI: User-friendly Human-Machine Interface (HMI) for setting parameters, diagnostics, and selecting wrapping programs. Research in industrial automation emphasizes the importance of intuitive controls for reducing setup time and operator error.

- Safety Systems: Comprehensive safety guarding, interlocked access doors, and emergency stop circuits meeting relevant safety standards (e.g., ISO 13849-1).

- Robust Construction: Heavy-duty steel frames and quality components designed for industrial environments, as expected by readers of publications like The Fabricator.

Advantages Over Manual or Semi-Automatic Methods

Implementing an automated orbital bubble film wrapper offers compelling benefits, frequently cited in manufacturing efficiency studies and supplier case studies:

- Superior Product Protection: Bubble film provides excellent cushioning against impacts, vibrations, and scratches. The consistent, tight wrap offered by orbital machines minimizes shifting and potential abrasion points. Studies in packaging dynamics confirm the value of void fill and cushioning in reducing transit damage.

- Increased Throughput: Automation significantly speeds up the wrapping process compared to manual application, directly boosting production line output.

- Reduced Labor Costs: Frees up personnel previously dedicated to manual wrapping for other value-added tasks.

- Optimized Material Usage: Precise control over film application and overlap ensures consistent usage, potentially reducing waste compared to inconsistent manual wrapping. While pre-stretch is less common for bubble film, controlled tension still optimizes coverage.

- Enhanced Load Security and Appearance: Produces a professional, uniform package that enhances product presentation and ensures the protective layer remains effective throughout the supply chain.

- Versatility: Capable of wrapping a wide range of product profiles beyond doors, including windows, furniture components, extrusions, lumber, and assembled kits.

Conclusion: Investing in Protective Packaging Automation

For manufacturers and fabricators dealing with doors, panels, and similar large, vulnerable products, the orbital bubble film wrapper presents a technologically advanced and economically sound solution. By automating the application of protective bubble film, these machines address key industry challenges related to product damage, labor costs, and operational efficiency. As highlighted in numerous industry reports and technical papers, investing in appropriate automation technology is crucial for maintaining competitiveness. The orbital wrapper, leveraging principles refined through patents and practical application, offers a clear path towards improved packaging quality, reduced costs, and enhanced customer satisfaction in demanding industrial environments.