COPPER COIL AND COPPR STRIP PACKING MACHINES

In the copper industry, there are many type proucts is in the coil form. Such as copper tube, copper wire, copper sheet, copper strip... Fhope providing efficiency copper coil packing machine per different packaging goal. The major solution is the coil wrapping machine for abobe copper coils packaging with paper, film, stretch film by eye through packaging.

Also Fhope providing the automatic copper packing solution to hlep our customer automation the step at the end of the production line. Our goal is to help the copper coil packing machine user can be huge benefits to the machine packing and automation system handling--and new technology is making it easier than ever to automate more steps of the copper packaging process.

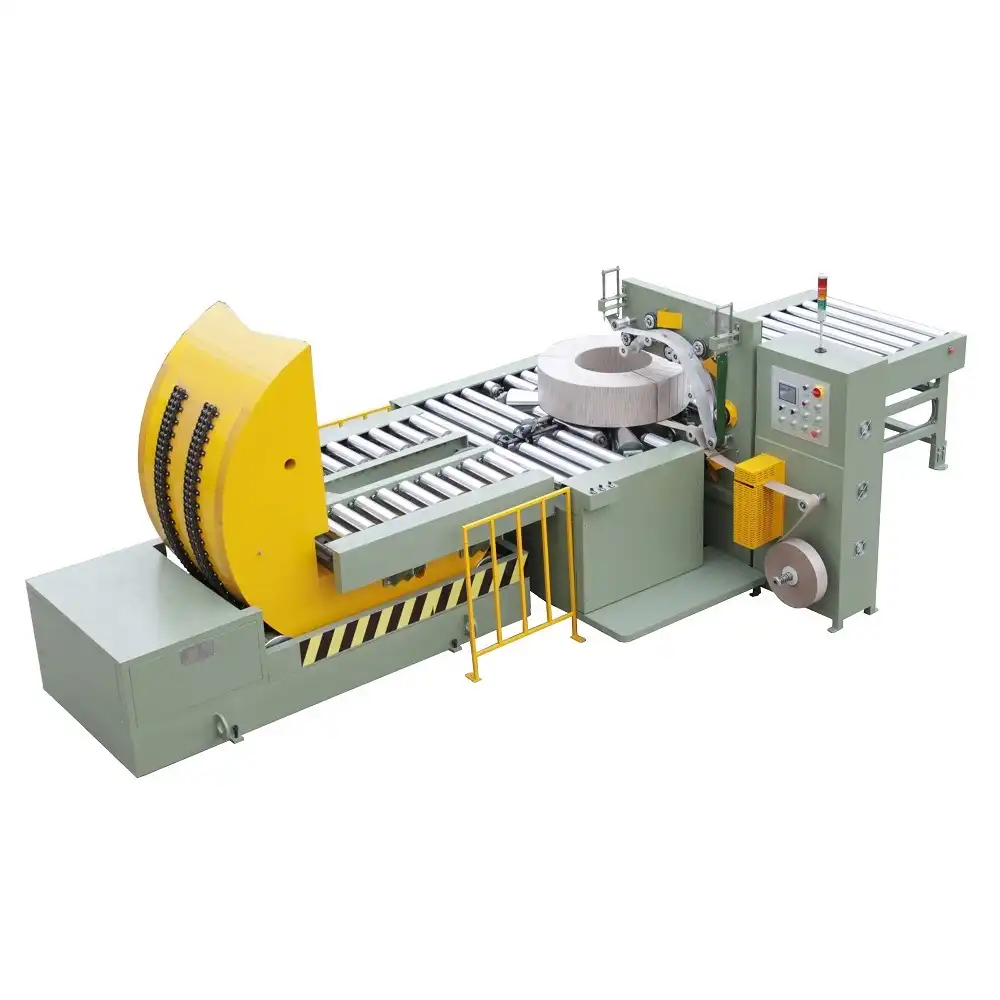

Description:

The FPC series is a coil stretch wrapper type machine specially designed for packaging copper materials. It is mainly suitable for packaging copper wire, copper coil, cable coil, steel coil and so on. The advantages of this kind machines are 100% efficient and perfect packaging appearance, saving labor cost and improving product competitiveness. Fhope group is committed to developing innovative ways to improve each step of the packing line: conveying, lifting,tilting ,wrapping and reducing defective rate of it.

BENIFIT OF THE COPPER COIL PACKIGN MACHINE IN PRODUCDTION

Better Production Speed: With the correct coppr packing machine in place, it’s feasible for companies to notably make better the production speed and product output. It’s not uncommon for an automated copper packing machine, for instance, to wrapping or shrinking items much more securely and many times swifter than the average employee. For some copper tube, copper coil manufacturer, there are looking for the automation in all factory. Becasued of the automated packaging solutions can also balanced and fold as many as steps of the packaging procedure into one single step. This way, these solutions liberate not just one employee, but possibly many. As a consequence, these technologies can both add on speeds and permit the packaging companies to move their staff to works that need human resources or actually benefit from the human touch. However, these automated systems can also make better the firmness of packaging and lessen the rate of flaws introduced during the packaging procedure.

Better Ergonomics and less Risk of Employee Injury: In copper coil manufacturing and packaging, where it’s usual for employees to do greatly repetitive tasks over long shifts, it’s not unusual for employees to degrade from work-connected musculoskeletal disorders (MSDs), sometimes termed as ergonomic injuries. These injuries are some of the very usual in industry, reasoning for one-third of all workplace injuries. They also commonly need more than a week of recovery time. Lessening the amount of repeated work that employees require to do can naturally lessen their risk of MSDs. Procedure of automation systems are beforehand a perfect fit for repetitive or mundane tasks since these works frequently benefit from coherence.

Features

Download

![]() Email: info@fhopepack.com

Email: info@fhopepack.com![]() Whatsapp: 0086-13951501635

Whatsapp: 0086-13951501635