Streamlining Wire Coil Packaging: An In-Depth Look at Automated Steel Wire Strapping Technology

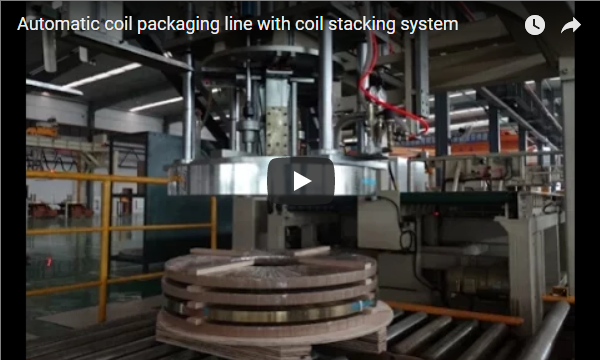

In the demanding environment of metal fabrication and wire production, efficient and secure packaging is paramount. Handling and strapping steel wire coils present unique challenges due to their weight, shape, and potential for unwinding. Manual strapping processes are often labor-intensive, time-consuming, and pose ergonomic risks, leading manufacturers to seek automated solutions. This article delves into the operational principles and benefits of automated steel wire coil strapping machines, referencing technological advancements highlighted in industry publications and technical papers.

The Challenge: Securing Steel Wire Coils Effectively

Manually strapping steel wire coils involves significant handling, inconsistent tension application, and potential safety hazards. Achieving uniform load containment is critical to prevent coil damage during storage and transportation. As noted in studies on packaging efficiency, inconsistent strap tension can compromise package integrity, leading to potential product loss or safety incidents (Source: Packaging Technology and Science journal articles often discuss load stability). Furthermore, the repetitive motions involved in manual strapping contribute to musculoskeletal disorders, impacting workforce productivity and increasing operational costs.

Automated Strapping Solutions: Enhancing Efficiency and Safety

Automated steel wire coil strapping machines are engineered to address these challenges directly. These systems typically employ orbital or through-eye strapping mechanisms designed specifically for coiled products.

Core Operational Principles:

Based on designs often detailed in patents (e.g., classes related to B65B - Packaging, conveying, or handling webs or strands), these machines automate several key steps:

- Coil Positioning: Sensors and conveyors accurately position the wire coil within the strapping zone.

- Strap Feeding: The strapping material (commonly high-tensile PET or steel strapping) is automatically fed around the coil's circumference or through its eye.

- Tensioning: Precision-controlled mechanisms apply consistent, predetermined tension to the strap, ensuring secure containment without damaging the wire. Research often focuses on optimizing tension algorithms for different coil types and strap materials.

- Sealing: The strap ends are securely joined, typically using friction-weld sealing for PET straps (known for high seal efficiency, often cited in technical comparisons) or notch/seal-less joints for steel straps.

- Cutting: The strap is cut cleanly, preparing the machine for the next cycle.

Key Features and Technical Specifications

Modern steel wire coil strapping machines incorporate advancements aimed at maximizing performance and reliability:

- Strapping Material Compatibility: Versatility to handle Polyethylene Terephthalate (PET) strap (e.g., 16mm - 32mm width, up to 1.2mm thickness) or steel strap, allowing manufacturers to choose based on cost, strength requirements, and sustainability goals.

- Tension Control: Advanced electronic or pneumatic tension systems providing adjustable ranges (e.g., 500 N - 7000 N), ensuring optimal load security for various coil sizes and weights. Consistent tension is a frequent focus in patent applications for strapping heads (USPTO examples).

- Sealing Technology: High-efficiency friction-weld sealing for PET offers joint strengths typically exceeding 85% of strap break strength, a figure often benchmarked in material science and packaging studies.

- Cycle Time: Optimized designs achieve rapid cycle times (e.g., 15-30 seconds per strap cycle, dependent on coil size and strap path), significantly boosting throughput compared to manual methods. The Fabricator frequently highlights cycle time reduction as a key metric for ROI in automation.

- Coil Capacity: Designed to accommodate a wide range of coil dimensions:

- Outer Diameter: e.g., 600mm - 1500mm

- Inner Diameter: e.g., 400mm - 800mm

- Width: e.g., 100mm - 800mm

- Control System: PLC (Programmable Logic Controller) based controls with user-friendly HMI (Human-Machine Interface) for easy operation, parameter adjustment, and diagnostics – aligning with Industry 4.0 integration trends discussed in manufacturing journals.

- Safety Features: Comprehensive guarding, safety interlocks, and emergency stop systems adhering to international safety standards (e.g., ISO 13849).

Operational Benefits in Fabrication Environments

Implementing automated strapping technology delivers tangible advantages:

- Enhanced Throughput: Drastic reduction in strapping time per coil increases overall packaging line speed.

- Improved Load Security & Product Protection: Consistent tension and reliable seals minimize coil movement and damage during handling and shipping.

- Reduced Labor Costs & Improved Ergonomics: Automation frees up personnel for higher-value tasks and significantly reduces the risk of repetitive strain injuries associated with manual strapping.

- Material Optimization: Precise tension control can potentially allow for the use of optimized strap specifications without compromising load security, leading to material cost savings.

- Process Consistency: Eliminates operator variability, ensuring every coil is strapped to the same high standard.

Conclusion

Automated steel wire coil strapping machines represent a significant technological advancement for the metal fabrication and wire industries. By leveraging principles refined through engineering research and protected by patents, these systems offer enhanced efficiency, improved safety, and superior load containment compared to traditional methods. As highlighted in publications like The Fabricator, investing in such automation is key to streamlining operations, reducing costs, and maintaining competitiveness in today's demanding market.

For more information on specific solutions tailored to your wire coil packaging needs:

Explore Wire Coil Wrapping Solutions

Discover Automatic Wire Winding Technology

Contact us to discuss your application: info@fhopepack.com