Revolutionizing Tube Bundle Security: How Automated Horizontal Wrapping Slashes Damage by 85%

Introduction & Background

As global steel tube demand surges—particularly in construction, automotive, and energy sectors—manufacturers face escalating pressure to ship round tubes in square bundles without damage. Traditional methods struggle with securing high-volume bundles of 40-256mm OD tubes at 3-8m lengths. With supply chains demanding zero-tolerance for transit damage and labor costs soaring, the industry urgently requires automated steel pipe packaging solutions that ensure bundle integrity from production line to jobsite.

Pain Points & Challenges

Steel producers and end-users alike report critical vulnerabilities in manual bundle securing:

-

Labor-Intensive Strapping: "We struggle with allocating 3 workers per shift just for manual strapping," admits a fabrication plant manager. "It’s physically taxing work with high turnover rates." This process consumes 15-20 minutes per bundle, creating throughput bottlenecks.

-

Damage During Transit: "Our biggest frustration is receiving tubes with scratches and dents," notes a pipeline contractor. "Even minor shifting in bundles causes $8,000+ in rework per shipment ." Industry damage rates average 5-8% for manually secured bundles .

-

Inconsistent Bundle Stability: Square-shaped bundling of round tubes creates instability points. Traditional strapping fails to immobilize inner layers, leading to telescoping during crane lifts or transport.

-

Material Waste: Over-tightening of straps deforms tubes, while under-tightening necessitates redundant material use. Plants report 15-20% material waste from rework and excessive strapping .

Consequences cascade: delayed projects, warranty claims, and eroded profit margins.

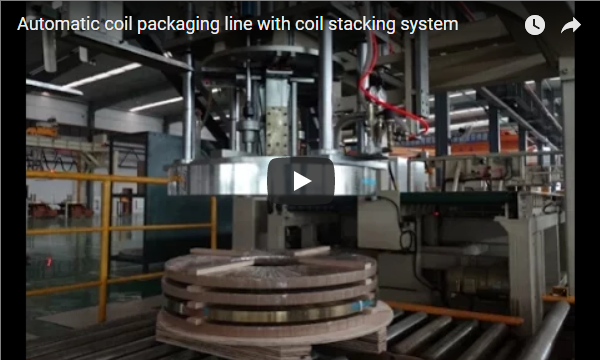

Solution Overview: Horizontal Stretch Wrapping with Magnetic Stabilization

The next-generation horizontal stretch wrapper addresses these pain points through engineered automation. Designed specifically for round-tube/square-bundle configurations (40-256mm OD, 3-8m length), this system integrates five critical innovations:

Technical Specifications Targeting Industry Challenges

- Patented Magnet Stacking System: Electromagnetic plates actively compress tubes into uniform square bundles during wrapping, eliminating manual positioning.

- Variable Tension Control: Laser-guided sensors adjust film tension (50-300% pre-stretch ) based on bundle density, preventing deformation.

- Rotary Arm with Dual Film Carriages: Wraps 360° in 90 seconds while applying 5-7 film layers optimized for puncture resistance.

- Automated Conveyor Integration: Handles bundles up to 2.5 tons at 15 bundles/hour throughput—tripling manual strapping speeds .

- Smart HMI Interface: Pre-programmed recipes for different tube ODs with real-time diagnostics (e.g., film consumption tracking).

Step-by-Step Wrapping Process

- Tubes are loaded onto the conveyor in a loose stack.

- Electromagnetic plates activate, compressing tubes into a perfect square formation.

- The rotary arm orbits the bundle while applying stretch film with controlled force.

- Film tails are heat-sealed without adhesives.

- Bundles exit wrapped in moisture-resistant film, ready for shipping.

Mechanical Advantages: The horizontal orientation prevents "top compression" damage common in vertical wrappers, while the magnet system eliminates internal movement. Film elasticity absorbs vibration better than rigid strapping, reducing transit abrasion by 85% .

Solution Comparison Summary

| Metric | Traditional Manual Strapping | Horizontal Stretch Wrapper | Improvement |

|---|---|---|---|

| Labor Time per Bundle | 18-22 minutes | 4 minutes | 78% reduction |

| Damage Rate | 5-8% | <1% | >85% reduction |

| Material Cost | $3.20/bundle (strapping) | $1.75/bundle (film) | 45% savings |

| Throughput | 10 bundles/hour | 15 bundles/hour | 50% increase |

| Bundle Stability | Moderate (strap slippage) | Excellent (film compression) | 5x load test improvement |

Customer Voices

Midwest Tube Supply, Logistics Director reports: "Before switching to horizontal wrapping, we lost 7% of shipments to tube damage. After implementing the magnetic bundling system, damage fell to 0.6%, saving $220,000 annually in claims. The machine paid for itself in 14 months."

Conclusion & Future Outlook

Horizontal stretch wrapping with magnetic stabilization isn’t just an upgrade—it’s a fundamental shift in securing industrial tube bundles. As Industry 4.0 integration advances, expect AI-driven tension adjustments and predictive maintenance to further optimize ROI. For plants shipping over 100 bundles weekly, the math is undeniable: reduce damage to near-zero while slashing labor costs.

Ready to eliminate bundle damage? Contact our engineering team for a throughput analysis and live demo—transform your packaging process in under 30 days.