Enhancing Pipe Coil Packaging with Automated Horizontal Stretch Wrapping Technology

The efficient and secure packaging of large pipe coils, particularly corrugated plastic or metal types, presents significant challenges in manufacturing and logistics environments. Manual or semi-automated methods often struggle with consistency, speed, and operator safety. Addressing these concerns, automated horizontal stretch wrapping systems provide a robust solution designed to optimize the unitization and protection of these demanding loads.

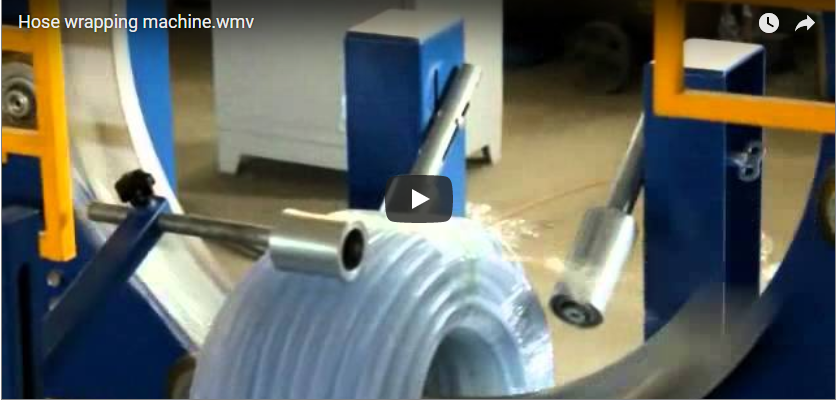

This type of high-speed horizontal stretch wrapping machine is specifically engineered for handling pipe coils, offering a streamlined, automated wrapping solution that enhances throughput, reduces packaging material consumption, and minimizes labor requirements.

Operating Principle and Design Features

Horizontal stretch wrappers operate by passing the stretch film through a dispensing carriage mounted on a rotating ring or arm. The pipe coil is conveyed horizontally through the center of this ring. As the ring rotates, it dispenses the stretch film, wrapping it around the circumference of the coil.

Key constructional and operational aspects often include:

- Robust Frame: Typically built with heavy-duty steel construction to withstand industrial environments and handle significant coil weights.

- Conveyor System: Integrated infeed and outfeed conveyors (often roller or belt types) facilitate automated loading and unloading, minimizing manual handling.

- Rotating Ring/Arm Assembly: The core wrapping mechanism, precisely balanced for high-speed rotation without excessive vibration.

- Film Delivery System: Modern systems incorporate powered pre-stretch carriages, a critical feature referenced in numerous packaging studies and patents (e.g., concepts related to optimizing film yield). Pre-stretch ratios (often adjustable up to 250-300%) significantly reduce film consumption compared to hand wrapping or machines without this feature, leading to substantial cost savings and improved load containment.

- Film Clamping and Cutting: Automated systems securely clamp the film at the start of the cycle and cut it cleanly at the end, ensuring a neat finish and preparing the machine for the next coil.

Technical Specifications Profile

While specific machine capabilities vary, typical performance parameters for industrial horizontal pipe coil wrappers include:

- Coil Diameter Range: Accommodating sizes often from 450mm (approx. 18 inches) up to 1800mm (approx. 72 inches) or more.

- Coil Weight Capacity: Designed to handle loads typically up to 2500 kg (approx. 5,000 pounds), sometimes higher for specialized applications.

- Stretch Film Compatibility: Utilizes standard LLDPE stretch film rolls, commonly in gauges from 17 to 30 microns (approx. 0.67 to 1.18 mil), though thicker films can be used depending on load requirements.

- Control System: PLC (Programmable Logic Controller) based controls with user-friendly HMI (Human-Machine Interface) for setting wrap parameters (e.g., rotation speed, film tension, number of wraps, overlap percentage).

- Drive Systems: Utilizes AC variable frequency drives (VFDs) for precise control over ring rotation and conveyor speeds, ensuring smooth acceleration and deceleration to prevent load shifting or damage.

Benefits of Automated Horizontal Wrapping

Implementing automated horizontal stretch wrapping offers tangible advantages:

- Enhanced Load Security and Protection: Consistent film tension and overlap create a tightly unitized wrapped coil, protecting it from dust, moisture, and potential damage during handling and safe transportation. This minimizes product loss and maintains package integrity.

- Increased Operational Efficiency: Automation significantly speeds up the packaging process compared to manual methods, boosting overall and throughput.

- Reduced Material Costs: Powered pre-stretch systems maximize film yield, leading to direct savings on consumable costs.

- Lower Labor Costs: Automation reduces the need for manual labor in the wrapping process, freeing up personnel for other value-added tasks.

- Improved Safety: Eliminates manual handling of heavy film rolls and the repetitive motions associated with hand wrapping, reducing the risk of worker injury. Features like safety fencing and interlocks prevent and ensure safe operation.

This result-driven packaging solution offered by horizontal coiling machine technology represents a strategic investment for manufacturers dealing with pipe coils, delivering measurable returns through enhanced efficiency, protection, and cost savings.

For more pipe coil packing machine options and details, explore further resources.