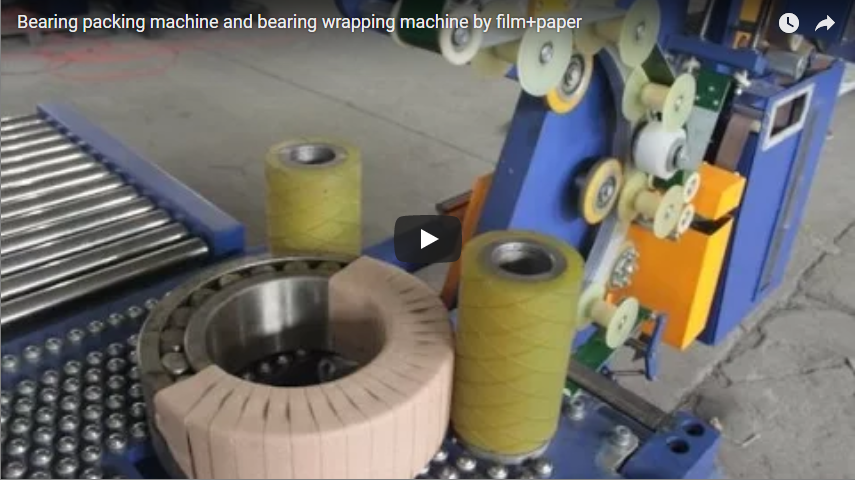

Protecting bearings during storage and transit is critical to maintaining their precision and preventing costly premature failures. Corrosion, dust, and physical damage are constant threats. Automated packaging solutions, such as the vertical bearing packing machine shown above, offer a robust defense, ensuring bearings reach their destination in optimal condition. This article delves into the technical specifications, design features, operational benefits, and user considerations of such equipment, aligning with the practical information needs of industry professionals.

1. Understanding the Vertical Bearing Packing Machine

A vertical bearing packing machine is specialized industrial equipment designed to automatically wrap bearings using protective materials like stretch film, VCI (Volatile Corrosion Inhibitor) paper, or crepe paper. The "vertical" designation refers to the orientation in which the bearing is typically held and rotated during the wrapping process, often advantageous for handling larger or heavier bearings and integrating seamlessly into specific production line layouts. Its primary function is to create a tightly sealed, protective layer around the bearing, shielding it from environmental contaminants and physical impacts.

2. Key Design and Structural Features

The effectiveness of a bearing packing machine stems from its thoughtful design and robust construction:

- Orbital Ring Wrapping System: The core of the machine involves a ring that orbits around the stationary or slowly rotating bearing. This ring carries the spool of packing material (e.g., stretch film, VCI paper). As the ring rotates, it dispenses and wraps the material securely around the bearing's outer and inner surfaces (depending on configuration), ensuring comprehensive coverage.

- Vertical Configuration Advantages: This orientation can simplify loading and unloading, especially for heavy bearings often handled by overhead cranes or manipulators. It can also offer a smaller footprint compared to some horizontal designs.

- Durable Frame Construction: Built typically from heavy-gauge steel, the frame is designed for stability and longevity in demanding industrial environments. This minimizes vibration during operation, contributing to consistent wrap quality.

- Integrated Conveyor Systems (Optional): Many machines can be integrated with powered or non-powered roller conveyors for automated infeed and outfeed, streamlining the packaging process within a larger production or logistics flow.

3. Core Components Breakdown

Understanding the key components provides insight into the machine's operation and capabilities:

- Wrapping Ring/Head: The dynamic component that orbits the bearing, carrying and applying the packing material. Its speed is often adjustable.

- Control System (PLC & HMI): Typically utilizes a Programmable Logic Controller (PLC) for reliable process automation. A Human-Machine Interface (HMI), often a touchscreen panel, allows operators to set parameters (wrap cycles, tension, overlap), monitor status, and troubleshoot issues.

- Adjustable Tension Control: Crucial for optimizing material usage and ensuring a secure wrap without damaging the bearing. This mechanism maintains consistent tension on the packing material as it's applied. The wrapping tension can be adjusted per specific needs.

- Material Dispensing Unit: Securely holds the roll of packing material and ensures smooth feeding to the wrapping ring. Quick-change mechanisms are desirable for minimizing downtime during material replenishment. The packing material is fixed adjacent to the orbital ring wrapper for efficient application.

- Safety Features: Essential elements include physical guarding around moving parts, emergency stop buttons, and potentially light curtains or safety interlocks to protect operators.

4. Technical Specifications Overview (Typical Ranges)

While exact specifications vary by model and manufacturer, here's a general parameter list to provide context:

- Applicable Bearing Outer Diameter (OD): 100 mm – 1500 mm (or wider ranges for specialized machines)

- Applicable Bearing Inner Diameter (ID): 50 mm – 1200 mm (dependent on OD)

- Applicable Bearing Width/Height: 20 mm – 500 mm

- Packing Material Compatibility:

- LLDPE Stretch Film (various widths/thicknesses)

- VCI Stretch Film

- VCI Paper / Poly-coated VCI Paper

- Crepe Paper

- Composite Paper Tape

- Wrapping Ring Speed: 50 – 150 RPM (adjustable)

- Packing Material Overlap Rate: 10% - 90% (adjustable via PLC/HMI)

- Control System: PLC (e.g., Siemens, Allen-Bradley, Omron) + HMI Touchscreen

- Power Requirements: 380V/50Hz/3Ph or customized (e.g., 480V/60Hz/3Ph)

- Compressed Air Requirement: 0.5 – 0.7 MPa (if pneumatic components are used)

- Machine Dimensions (L x W x H): Varies significantly based on capacity (e.g., 2500mm x 2000mm x 2300mm)

Note: These are illustrative ranges. Always refer to specific manufacturer documentation for precise data.

5. Operational Process and User Experience

A typical operational cycle involves:

- Loading: The bearing is placed onto the machine's support rollers or conveyor section, often manually or via handling equipment.

- Positioning: The bearing is automatically or manually positioned correctly within the wrapping ring's path.

- Wrapping Cycle Initiation: The operator starts the cycle via the HMI.

- Automatic Wrapping: The ring orbits the bearing, applying the selected material with pre-set tension and overlap. The bearing may rotate slowly for even coverage. Cut-and-clamp mechanisms automatically handle the start and end of the material.

- Unloading: Once the cycle is complete, the wrapped bearing is removed from the machine.

User Experience Factors:

- Ease of Adjustment: Intuitive HMI controls for modifying wrapping parameters (tension, speed, number of wraps, overlap percentage) are critical for handling different bearing sizes and protection requirements.

- Material Loading: Simple and quick roll change procedures minimize downtime.

- Maintenance Access: Well-designed machines provide easy access to key components like motors, sensors, and the wrapping ring for routine maintenance and troubleshooting.

6. Benefits of Automated Bearing Packaging

Investing in a vertical bearing packing machine delivers tangible advantages:

- Enhanced Protection: Creates a consistent, tight seal against moisture, dust, and corrosive elements (especially when using VCI materials). Reduces risk of scratches and dings during handling.

- Increased Efficiency & Throughput: Significantly faster than manual wrapping methods, increasing packaging line output.

- Labor Cost Reduction: Frees up personnel from manual wrapping tasks for higher-value activities.

- Packaging Consistency: Ensures every bearing receives the same level of protection, improving quality control.

- Material Optimization: Precise tension and overlap control can reduce excessive material consumption compared to manual methods.

7. Material Selection Considerations

The choice of wrapping material is crucial and depends on the required level of protection and storage duration:

- LLDPE Stretch Film: Provides good physical protection, dust barrier, and load stability. Cost-effective for general purposes.

- VCI Stretch Film/Paper: Impregnated with Volatile Corrosion Inhibitors that create a protective molecular layer on the bearing surface, ideal for long-term storage or shipping in corrosive environments.

- Crepe Paper/Composite Tapes: Offers cushioning and moisture absorption, often used in conjunction with or as an alternative to film.

The machine's versatility in handling different material types, as highlighted originally ("wrapping material can be chosen per your need"), is a key selling point.

Conclusion

Automated vertical bearing packing machines represent a significant upgrade over manual methods, offering superior protection, efficiency, and consistency. By understanding their design, components, operational parameters, and the benefits they provide, manufacturers and logistics operators can make informed decisions to safeguard valuable bearing assets throughout the supply chain. The ability to adjust parameters like wrapping tension and select appropriate materials ensures adaptability for diverse bearing types and protection requirements.

For more detailed information on specific models and configurations, explore resources like the Fhopepack Bearing Packing Machine page: https://www.fhopepack.com/Bearing-packing-machine/