Advanced Automatic Packaging Machine for Large Bearings (OD 300-1500mm)

Handling and packaging large industrial bearings presents unique challenges due to their size, weight, and susceptibility to corrosion and contamination. Manual packaging processes can be slow, labor-intensive, and inconsistent. FHOPEPACK addresses these challenges with specialized automatic bearing packaging machinery designed for efficiency and superior protection.

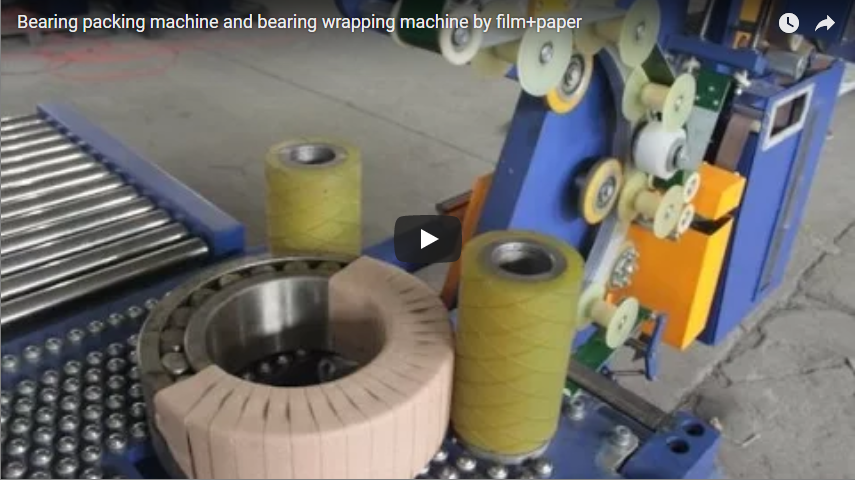

Video caption: Demonstration of the FHOPE automatic bearing packaging machine in operation.

1. The Challenge: Protecting Large, High-Value Bearings

Large bearings, often critical components in heavy machinery, require robust packaging solutions that ensure they arrive at their destination in pristine condition. Key considerations include:

- Corrosion Prevention: Exposure to moisture and contaminants can quickly damage bearing surfaces.

- Physical Protection: Shielding against impacts and vibrations during transit is crucial.

- Handling Efficiency: Safely and efficiently moving and wrapping heavy bearings requires automation.

- Consistency: Automated systems ensure uniform application of protective materials for reliable results.

2. FHOPE's Automated Solution: Tailored for Large Bearing Packaging

FHOPEPACK offers an advanced automatic bearing packaging machine specifically engineered for large bearings with an outer diameter (OD) ranging from 300mm to 1500mm. This system streamlines the packaging process, moving beyond simple wrapping to provide a comprehensive online packaging solution integrated into production or logistics flows.

3. Key Features and Technical Specifications

This machine incorporates several features designed for optimal performance and ease of use:

-

Wide Size Range:

- Accommodates bearings with OD: 300mm - 1500mm.

- Suitable for various heavy industrial bearing types.

-

Multi-Layer Packaging Capability:

- Applies two or more layers of packaging material simultaneously or sequentially (e.g., VCI film followed by stretch wrap).

- This layered approach significantly enhances protection against environmental factors and physical damage, ensuring bearing integrity.

-

Advanced Automation:

- Automatic Film Feeding: Initiates the wrapping cycle by automatically feeding the selected packaging film (like stretch film or VCI film) to the bearing.

- Automatic Material Cutting: Precisely cuts the packaging material based on pre-programmed length calculations derived from the bearing's dimensions, minimizing waste and ensuring a clean finish.

- PLC Control System: Typically managed via a Programmable Logic Controller (PLC) with a user-friendly interface for setting parameters and monitoring the process.

-

Material Compatibility:

- Designed to work effectively with various packaging materials, including:

- LLDPE Stretch Film

- VCI (Volatile Corrosion Inhibitor) Film

- HDPE Film

- Compound Paper Tape

- Designed to work effectively with various packaging materials, including:

4. Operational Efficiency and Benefits

Implementing FHOPE's automatic bearing wrapping solution delivers tangible benefits:

- Increased Throughput: Significantly faster than manual wrapping, boosting overall packaging line efficiency.

- Reduced Labor Costs: Automation minimizes the need for manual intervention in the wrapping process.

- Improved Package Quality: Consistent tension control and precise material application lead to secure, stable, and well-protected packages.

- Enhanced Protection: Multi-layer wrapping combined with materials like VCI film provides superior defense against corrosion and damage.

- Material Savings: Optimized wrapping programs and precise cutting reduce film consumption compared to manual methods.

5. User Experience Insights

From our experience in deploying these systems, clients consistently highlight the ease of integration and the reliability of the automated functions. Operators often comment on the intuitive controls and the noticeable reduction in physical strain associated with handling large bearings and bulky packaging materials. The automated feeding and cutting, in particular, are frequently cited as major improvements, eliminating common bottlenecks and ensuring a consistent, professional package appearance every time.

6. Customization and Support

As an Original Design Manufacturer (ODM), FHOPEPACK collaborates with clients to provide tailored bearing packaging solutions. This can include modifications to handling capacities, integration with existing conveyor systems, or specific programming requirements to meet unique operational needs.

For further details on bearing packing machines and customized packaging solutions, please visit our dedicated page or contact our technical team.

More bearing packing machine videos and bespoke packing solutions are available from the ODM manufacturer. Contact us for inquiries: info@fhopepack.com