Automated Bearing Packaging: Enhancing Protection and Efficiency with Advanced Wrapping Technology

In modern manufacturing and logistics, the proper packaging of precision components like bearings is paramount. Bearings are susceptible to contamination, physical damage, and, critically, corrosion during storage and transit. Manual or semi-automated packaging processes often fall short, leading to inconsistencies, increased labor costs, and potential product degradation. Addressing these challenges requires sophisticated automated solutions that ensure both protection and operational efficiency.

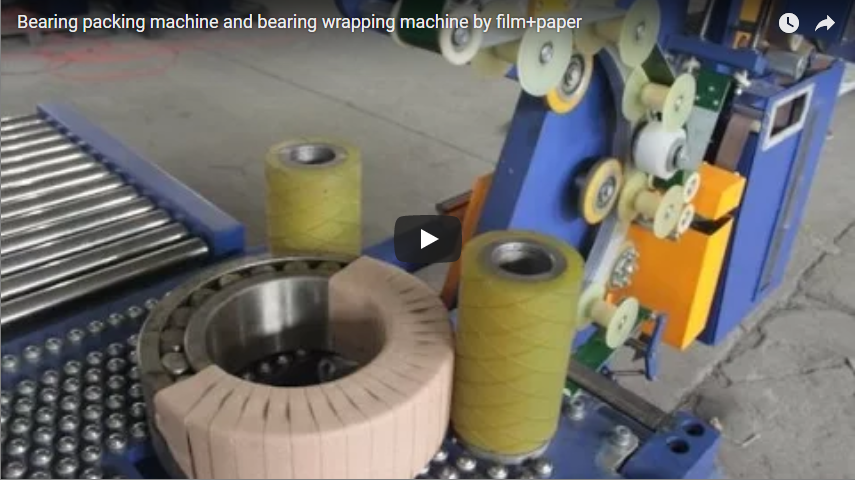

Fhopepack's online bearing packing machine represents a significant advancement in automated packaging systems, specifically engineered to meet the rigorous demands of the bearing industry. This integrated system streamlines the packaging workflow, moving beyond simple wrapping to provide a comprehensive protection strategy.

System Components and Workflow Integration

The standard configuration integrates seamlessly into existing production or warehousing lines, typically comprising:

- In-feed Conveyor: Automates the delivery of bearings to the wrapping station, ensuring consistent flow and minimizing manual handling. Integration with upstream processes is key for maximizing throughput.

- Automatic Bearing Wrapper: The core of the system, featuring advanced mechanisms for precise positioning and wrapping.

- Out-feed Conveyor: Transports the fully packaged bearings downstream for palletizing, storage, or shipping.

Key Technologies and Mechanisms Driving Performance

The effectiveness of automated bearing wrapping hinges on precision engineering and intelligent control. Several core technologies contribute to its performance:

- Automated Positioning and Guiding: Incorporating sensors and actuators, potentially drawing on principles outlined in patents related to automated handling of annular objects, the system accurately centers and secures the bearing. This ensures the wrapping material is applied uniformly, crucial for consistent protection. Research consistently highlights improper handling as a source of premature bearing failure, making precise automated positioning vital.

- Supportive Roller System: Base-mounted rollers provide stable support, accommodating various bearing sizes. This system often includes lifting capabilities and enables smooth 360-degree rotation of the bearing, facilitating complete ring wrapping without manual intervention. This mechanism ensures comprehensive coverage, particularly important when applying VCI (Volatile Corrosion Inhibitor) materials.

- Optimized Wrapping Cycle: The wrapping head applies materials like stretch film, VCI paper, or barrier films with controlled tension. This ensures a tight, secure wrap that minimizes moisture ingress and provides physical cushioning. The process adheres to principles discussed in packaging science literature regarding barrier properties and corrosion prevention.

- PLC Control and HMI Interface: Modern systems utilize Programmable Logic Controllers (PLCs) for reliable process automation and Human-Machine Interfaces (HMIs) for intuitive operation, parameter adjustments (e.g., overlap ratio, tension), and diagnostics.

Performance Metrics and Specifications

While specific parameters vary by model and configuration, typical performance characteristics include:

- Packaging Speed: 25-45 seconds per bearing (depending on size and wrapping requirements).

- Bearing Size Compatibility: Designed to handle a range of inner diameters (ID), outer diameters (OD), and widths (specify typical ranges if known, e.g., OD 100-500mm, Width 20-150mm).

- Wrapping Materials: Compatible with standard packaging materials including PE stretch film, VCI stretch film, VCI paper, crepe paper, and laminated barrier films.

- Control System: PLC-based automation.

- Power Requirements: Standard industrial power supply (e.g., 480V, 3-Phase, 60Hz or local equivalent).

Tangible Benefits for Fabricators and Manufacturers

Investing in automated bearing packaging technology delivers measurable advantages:

- Enhanced Corrosion Protection: Consistent application of VCI materials or barrier films creates a protective microenvironment, significantly reducing the risk of corrosion – a major concern highlighted in bearing maintenance and failure analysis studies.

- Increased Throughput: Automation dramatically increases packaging speed compared to manual methods, directly impacting overall production or distribution capacity.

- Improved Consistency and Quality: Automated wrapping ensures every bearing receives the same level of protection, eliminating human variability and enhancing product quality perception.

- Labor Optimization: Reduces reliance on manual labor for a repetitive and physically demanding task, freeing up personnel for higher-value activities and improving workplace ergonomics.

- Reduced Material Waste: Precise control over material application and tension can optimize film or paper usage compared to manual wrapping.

- Seamless Integration: Designed for integration into larger automated production or logistics systems, contributing to overall operational efficiency.

Scalability and Advanced Automation

Beyond standalone machines, the trend leans towards fully integrated packaging lines. For manufacturers seeking comprehensive, high-level automation, options for a complete [Bearing packing line](https://www.fhopepack.com/Bearing-packing-machine/bearing-packing-line.html) are available, potentially incorporating additional modules like automated weighing, labeling, stacking, or palletizing. This reflects the broader industry push towards end-to-end automation, a frequent topic in publications like The Fabricator, emphasizing efficiency gains and process control.

Conclusion

Automated bearing packaging machines, such as the online system developed by Fhopepack, offer a technologically advanced solution to the critical task of protecting bearings. By combining precision handling, optimized wrapping cycles, and seamless integration capabilities, these systems deliver significant improvements in efficiency, protection quality, and operational consistency. For businesses involved in the manufacturing, distribution, or refurbishment of bearings, adopting such automation is a strategic investment in product integrity and operational excellence.