Elevating Packaging Standards: A Deep Dive into Horizontal Wrapping Machines for Profiles, Tubes, and Long Materials

In today's fast-paced industrial landscape, efficiency and product integrity during transit are paramount. For businesses dealing with long, narrow items like aluminum profiles, steel tubes, copper pipes, timber, or plastic extrusions, conventional packaging methods often fall short, leading to potential damage, increased labor costs, and logistical headaches. Enter the horizontal wrapping machine – a specialized, automated solution designed to tackle these specific challenges head-on.

From our experience working with manufacturers and distributors across various sectors, the transition to automated wrapping isn't just about speed; it's a strategic move towards operational excellence and enhanced product protection.

1. The Unique Challenge: Securing Long and Narrow Products

Manually wrapping long items is notoriously time-consuming, inconsistent, and physically demanding. Achieving a uniform, protective layer of stretch film or other wrapping materials is difficult, leaving products vulnerable to:

- Surface Damage: Scratches, abrasions, and dents during handling and transport.

- Environmental Factors: Moisture, dust, and corrosion, particularly for metal products.

- Instability: Loose bundles can shift, leading to damage or safety hazards.

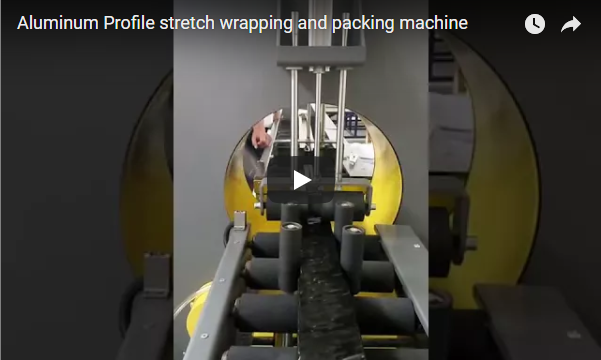

2. The Solution: Horizontal Orbital Wrapping Technology

A horizontal stretch wrapping machine, often called an orbital wrapper, operates on a simple yet ingenious principle. The product moves horizontally on a conveyor system through a rotating ring (or eye) that dispenses the packaging material (typically stretch film) around the product's circumference. This continuous orbital wrapping process ensures a tight, consistent, and protective cocoon around the entire length of the item.

3. Technical Specifications & Performance Capabilities

Modern horizontal wrappers offer a range of features designed for performance and versatility. While specific models vary, key technical aspects often include:

- Control System: Typically utilizes Programmable Logic Controllers (PLCs) with user-friendly Human-Machine Interfaces (HMIs) for easy setup and operation parameter adjustments (e.g., wrapping overlap, tension, conveyor speed).

- Wrapping Ring: Variable speed rotation (measured in RPM) to accommodate different product types and throughput requirements. High-speed rings are available for demanding production lines.

- Film Delivery System: Advanced pre-stretch carriages that can elongate stretch film by up to 250-300%. This optimizes film usage (reducing costs) and provides superior load containment. Adjustable film tension control is critical.

- Conveyor Systems: Options include powered roller conveyors, belt conveyors, or specialized V-block conveyors to securely support different product profiles. Infeed and outfeed conveyors automate the handling process.

- Automation Level: Machines range from semi-automatic (requiring manual initiation and film cutting) to fully automatic systems with automatic product clamping, film application, cutting, and sealing.

- Safety Features: Interlocked guarding, emergency stop buttons, and light curtains are essential for operator safety.

Technical Data Comparison: Manual vs. Horizontal Wrapping

| Feature | Manual Wrapping | Horizontal Wrapping Machine |

|---|---|---|

| Speed | Slow, operator-dependent (e.g., few bundles/hr) | High, consistent (e.g., 20-60+ bundles/hr) |

| Consistency | Variable, depends on operator skill | Highly consistent wrap tension & overlap |

| Labor | Labor-intensive (often requires 2+ people) | Minimal operator intervention (often 1 operator) |

| Film Usage | High, inconsistent stretching | Optimized via pre-stretch (up to 50% savings) |

| Protection | Moderate, prone to gaps & looseness | Excellent, tight & uniform coverage |

| Safety | Higher risk of strains, repetitive motion | Safer, automated process |

4. Key Benefits: Beyond Just Wrapping

Investing in a horizontal wrapping machine delivers tangible advantages:

- Enhanced Product Protection: The tight, uniform wrap shields products effectively from scratches, dust, moisture, and UV radiation (with appropriate film). This significantly reduces damage claims and maintains product quality upon arrival.

- Increased Operational Efficiency: Automation drastically cuts down wrapping time compared to manual methods. Continuous operation capabilities mean products flow smoothly through the packaging line, eliminating bottlenecks and increasing overall throughput. We've seen clients double or even triple their packaging output.

- Reduced Labor Costs & Improved Safety: By automating a physically demanding task, these machines reduce the need for manual labor, freeing up personnel for higher-value activities. This also minimizes the risk of workplace injuries associated with manual wrapping.

- Optimized Material Consumption: The pre-stretch function significantly reduces the amount of stretch film required per wrap, leading to direct cost savings and a more sustainable packaging process.

- Professional Presentation: Consistently wrapped products project a professional image and enhance brand perception.

5. Industries Served & Applications

Horizontal wrapping machines are indispensable in various industries, including:

- Metal Processing: Wrapping aluminum extrusions, steel pipes, copper tubes, metal bars.

- Building & Construction: Packaging timber, PVC profiles, plastic pipes, insulation panels.

- Manufacturing: Securing long components, rolls of fabric or carpet, furniture parts.

- Automotive: Wrapping exhaust pipes, structural components.

6. Fhopepack: Reliable and Cost-Effective Wrapping Solutions

Fhopepack specializes in manufacturing robust and reliable horizontal stretch wrapping machines tailored for long and narrow products. Our machines are engineered for:

- Ease of Operation: Intuitive controls minimize training time and ensure smooth operation.

- Durability: Built with quality components for longevity in demanding industrial environments.

- Performance: Designed for efficient, high-speed wrapping with consistent results.

- Cost-Effectiveness: Offering a strong return on investment through labor savings, reduced film consumption, and minimized product damage.

Our focus is on providing solutions that integrate seamlessly into your existing production lines, delivering immediate improvements in efficiency and protection.

7. Choosing the Right Machine

Selecting the appropriate horizontal wrapper involves considering:

- Product Dimensions: Maximum and minimum length, width, and height.

- Product Weight: The conveyor system must handle the load.

- Throughput Requirements: Bundles or items per hour needed.

- Level of Automation: Semi-automatic vs. fully automatic.

- Budget: Balancing initial investment with long-term ROI.

Conclusion: A Strategic Investment in Packaging Excellence

For companies handling long profiles, tubes, or similar materials, a horizontal wrapping machine isn't just equipment; it's a strategic investment. It streamlines operations, safeguards products, reduces costs, and ultimately contributes to a more efficient and profitable business. By embracing this technology, you elevate your packaging standards to meet the demands of modern logistics and customer expectations.

Explore tailored solutions for your specific needs:

https://www.fhopepack.com/Horizontal_wrapping_machine.html