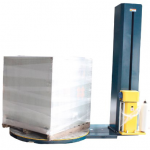

A stretch wrapping machine is a piece of equipment used to wrap a pallet of goods with stretch film, which provides a secure and protective layer around the products during transportation and storage. The packing process for a stretch wrapping machine typically involves the following steps:

1. Load the pallet: The pallet is loaded with the goods to be wrapped in a stable and secure manner, ensuring that the load is evenly distributed on the pallet.

2. Attach the film: The beginning of the stretch film is attached to the pallet or the film roll holder on the machine. The film is then pulled across the load and attached to the opposite side.

3. Start the wrapping process: The stretch wrapping machine is started, and the turntable or rotating arm begins to move around the pallet, applying the stretch film in a spiral pattern. The film is stretched as it is applied, creating tension that holds the load in place.

4. Adjust the settings: The operator may adjust the wrapping settings, such as the number of revolutions or the stretch film tension, depending on the requirements of the load being wrapped.

5. Complete the wrapping: The wrapping process is completed when the entire load is covered with the stretch film. The film is then cut and secured to the pallet.

6. Move the pallet: Once the wrapping is complete, the pallet can be moved to its destination, ready for transportation or storage.

Using a stretch wrapping machine for pallet packing can help to increase productivity and efficiency in the packaging process. It also provides added protection for the goods being transported or stored, reducing the risk of damage or loss.

https://www.fhopepack.com/Stretch_wrapping_machine.html

info@fhopepack.com