1. Addressing Critical Challenges in Wire Coil Handling and Packaging

The manual handling and packaging of heavy wire rods, rolls, and coils present significant operational challenges and safety risks within the manufacturing and distribution sectors. Traditional methods often involve labor-intensive processes prone to inconsistencies and potential workplace accidents. Key issues include:

- Safety Hazards: Manual manipulation of heavy coils (often exceeding several tons) carries a high risk of dropped loads, leading to severe injuries and equipment damage. Repetitive strain injuries are also a concern for personnel.

- Efficiency Bottlenecks: Manual wrapping is inherently slow and requires skilled operators to achieve a consistent, secure wrap. This often limits overall production throughput and struggles to meet fluctuating market demands.

- Inconsistent Package Quality: Achieving uniform tension and overlap manually is difficult, potentially compromising the protective integrity of the packaging during transit and storage. This can lead to product damage from moisture, corrosion, or physical impact.

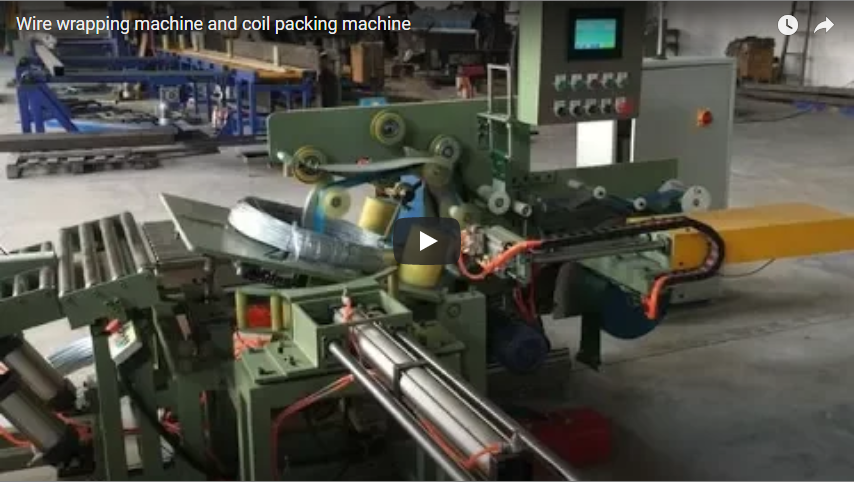

Our advanced wire coil wrapping machine is engineered specifically to overcome these obstacles, offering an automated, reliable, and efficient packaging solution. The embedded video showcases the machine in operation, demonstrating its capability to enhance both safety protocols and production output.

2. Engineering Design: A Tailored Solution for Diverse Wire Coil Specifications

Recognizing that wire coil dimensions and weights vary significantly across applications, our automatic wire coil wrapper features a robust and adaptable design architecture. The core engineering principles focus on flexibility, durability, and precision control.

- Customizable Framework: The machine's structure is engineered to accommodate a wide range of product sizes. Key adjustable parameters include:

- Coil Inner Diameter (ID): 400 mm - 800 mm

- Coil Outer Diameter (OD): 1000 mm - 2000 mm

- Coil Height/Width: 300 mm - 600 mm

- Heavy-Duty Load Capacity: Designed with high-strength materials and structural integrity, the machine reliably handles coils weighing up to 10 tons (10,000 kg).

- Versatile Wire Gauge Handling: Suitable for packaging wire with diameters ranging from fine 0.5 mm up to substantial 20 mm.

- Material Compatibility: The wrapping system is compatible with various packaging films, allowing selection based on specific protection requirements:

- PVC (Polyvinyl Chloride) Film

- PE (Polyethylene) Stretch Film

- LLDPE (Linear Low-Density Polyethylene) Stretch Film

- Specialty Anti-Corrosion Films (e.g., VCI - Volatile Corrosion Inhibitor)

This semi-automatic configuration combines automated wrapping efficiency with manual adjustments for size changeovers, offering a balance between performance and cost-effectiveness.

3. Technical Specifications Overview

For engineers and procurement specialists evaluating packaging solutions, precise technical data is paramount. Below is a summary of the key specifications for our wire roll wrapping machine:

- Coil Handling Capabilities:

- Inner Diameter (ID): 400 - 800 mm

- Outer Diameter (OD): 1000 - 2000 mm

- Height / Width: 300 - 600 mm

- Maximum Load: 10,000 kg (10 Tons)

- Applicable Wire Diameter: 0.5 mm - 20 mm

- Performance Metrics:

- Wrapping Efficiency: Up to 20 coils per hour (dependent on coil size and wrap cycles)

- Ring Speed: Variable, PLC controlled (Specify typical RPM range if available, e.g., 40-90 RPM)

- Overlap Rate: Adjustable (e.g., 20% - 80%), ensuring complete coverage

- Machine Dimensions & Utilities:

- Overall Length: ~2500 mm

- Overall Width: ~1600 mm

- Overall Height: ~1800 mm

- Machine Weight: ~1200 kg

- Power Supply: 380V/50Hz or 440V/60Hz (3-Phase), customizable

- Power Consumption: (Specify typical kW rating, e.g., Approx. 3.5 kW), includes energy-saving mode.

- Control System:

- Controller: Programmable Logic Controller (PLC) - (Specify brand if possible, e.g., Siemens, Allen-Bradley)

- Operator Interface: LCD Touch Screen (HMI) with Keypad Input

- Program Memory: Storage for multiple wrapping recipes/parameters

Data Comparison Note: Compared to manual methods which might average 5-7 coils per hour per team, this machine offers a 200-300% increase in throughput with significantly reduced labor.

4. Key Components and Construction

The reliability and performance of the wire coil packaging machine stem from its high-quality components and robust construction:

- Main Frame: Fabricated from heavy-gauge structural steel, ensuring stability and longevity under heavy loads. Often powder-coated for corrosion resistance.

- Rotating Ring: Typically constructed from durable aluminum alloy or steel, driven by a reliable friction wheel system or gear motor for smooth, high-speed rotation.

- Conveyor / Support Rollers: Heavy-duty steel rollers (potentially PU-coated to protect delicate wire surfaces) support and position the coil during wrapping. Options include driven or non-driven rollers depending on integration needs.

- Film Delivery System: Features a carriage that dispenses the wrapping material. Advanced systems include powered pre-stretch capabilities (e.g., up to 250%) to maximize film yield and ensure consistent tension control.

- Control Panel: Houses the PLC, HMI, frequency inverters, and electrical components, providing centralized control and monitoring.

- Safety Features: Incorporates essential safety elements like emergency stop buttons, safety interlocks on access doors/gates, and potentially light curtains or safety scanners for enhanced operator protection.

5. Operational Advantages and Enhanced Efficiency

Integrating this automated steel wire coil packaging machine yields substantial operational benefits:

- Drastically Increased Throughput: Wrapping up to 20 coils per hour significantly accelerates the packaging process, reducing bottlenecks and increasing overall plant capacity.

- Labor Cost Reduction: Automating the wrapping sequence minimizes the need for manual labor, freeing up personnel for other value-added tasks and reducing direct labor costs associated with packaging. Potential for rapid Return on Investment (ROI).

- Improved Package Security & Quality: Consistent, machine-controlled wrapping ensures uniform tension and overlap, leading to tightly secured, stable loads better protected against environmental factors and handling stresses.

- Enhanced Workplace Safety: Eliminates the high risks associated with manual handling of heavy coils. Features like automatic shutdown during malfunctions further contribute to a safer working environment.

- Simplified Maintenance: Designed for durability and ease of maintenance. Routine tasks are straightforward, and easy-to-replace components minimize downtime.

- Data-Driven Operation: The PLC and HMI interface allow for precise control over wrapping parameters (e.g., rotation speed, overlap percentage, number of wraps), storage of different product recipes, and potentially data logging for quality control and process analysis.

6. User Experience: Intuitive Control and Maintenance

The machine is designed with the operator in mind:

- User-Friendly Interface: The HMI provides intuitive controls for setting parameters, selecting recipes, starting/stopping cycles, and monitoring machine status. Fault diagnostics are typically displayed clearly to aid troubleshooting.

- Easy Material Loading: Film roll replacement is designed to be quick and straightforward, minimizing changeover time.

- Routine Maintenance: Access points for lubrication and inspection are designed for convenience. The manual provides clear instructions for scheduled preventative maintenance tasks.

7. Conclusion and Next Steps

This heavy-duty coil wrapper represents a significant upgrade from manual or outdated packaging methods. By automating the wire coil wrapping process, manufacturers can achieve substantial improvements in efficiency, safety, and package quality, ultimately strengthening their competitive position. The machine's robust design, customizable specifications, and advanced control system provide a reliable and future-proof solution for diverse wire packaging needs.

Interested in exploring how this automated wrapping solution can optimize your specific operations? Contact us today to:

- Request a detailed quotation tailored to your coil specifications.

- Schedule a virtual or in-person demonstration.

- Discuss customization options and integration possibilities with our engineering team.

- Receive comprehensive product specifications and technical documentation.

8. Frequently Asked Questions (FAQs)

1. How adaptable is the machine to different coil sizes within its specified range?

The machine features manual adjustment mechanisms (e.g., adjustable support rollers, potentially repositionable guide rollers) to accommodate the specified range of inner diameters, outer diameters, and heights. Changeovers are typically straightforward but require operator input. Fully automated adjustments can be explored as a customization option.

2. What specific safety mechanisms are integrated into the design?

Standard safety features include prominent Emergency Stop buttons, safety interlocks on guarding doors (preventing operation if open), and automatic fault detection with shutdown protocols managed by the PLC. Optional enhancements like light curtains at entry/exit points can further enhance operator safety.

3. How does the energy-saving mode function?

The energy-saving mode typically involves automatically powering down certain components (like main drives or HMI backlights) after a preset period of inactivity, reducing passive power consumption during idle times. The machine quickly returns to operational status when needed.

Enhance your wire coil packaging process with our state-of-the-art, reliable, and efficient wrapping solution. Reach out today for more information.