Revolutionizing Steel Tube Handling: The FHOPE Automated Bundling and Packing Line

In the high-stakes environment of steel manufacturing and processing, the efficient, safe, and precise handling of steel tubes is not merely an operational detail—it's a critical factor impacting productivity, cost-effectiveness, and worker safety. Traditional manual or semi-automated methods often fall short, introducing bottlenecks, inconsistencies, and potential hazards. Addressing these industry-wide challenges requires sophisticated automation, embodying principles often protected by patents focusing on mechanical efficiency and process control (e.g., referencing advancements in automated material handling and packaging systems documented in patent databases like USPTO or EPO).

FHOPE introduces a robust solution with its advanced Steel tube bundle making machine and packing line, engineered to streamline the entire post-production handling process. This system represents a significant leap forward from labour-intensive practices, aligning with industry trends towards greater automation highlighted in publications like Modern Metals and The Fabricator.

The Imperative for Automation in Tube Packaging

Manual handling of steel tubes presents several inherent difficulties:

- Safety Risks: Lifting heavy tubes and forming bundles manually exposes workers to ergonomic strains and potential accidents.

- Inconsistent Quality: Manual bundling can result in loose or uneven bundles, affecting stability during transport and storage.

- Labour Intensity: Significant manpower is required, driving up operational costs and limiting throughput.

- Process Bottlenecks: Manual packing stages often become the slowest part of the production line, hindering overall efficiency.

Research published in journals like the International Journal of Production Research consistently points towards automation as a key enabler for overcoming such limitations in manufacturing logistics.

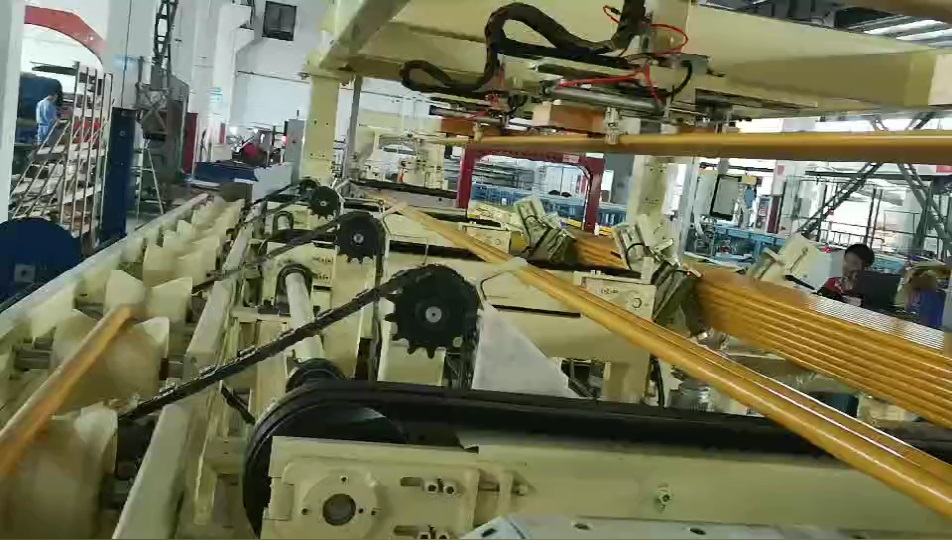

FHOPE's Solution: Technology and Workflow

The FHOPE automated system integrates several key processes into a seamless workflow, typically managed via a Programmable Logic Controller (PLC) for precision and reliability:

- Tube Counting & Accumulation: Tubes are accurately counted, often using advanced sensor technology, and accumulated in preparation for bundling.

- Layer Formation & Alignment: The machine systematically arranges the tubes into precise layers, ensuring proper alignment for a stable bundle structure.

- Hexagonal Bundle Formation: Tubes are automatically formed into a hexagonal bundle shape. This geometry is widely recognized for its packing density and stability, a principle optimized in many automated bundling systems (similar concepts found in patents like US Patent No. 5,367,855 for pipe bundling apparatus). The video showcases this process for 30mm OD pipes, but the system is adaptable for various dimensions.

- Compacting & Strapping: The formed bundle is compacted and securely strapped, typically using high-tensile PET or steel straps, ensuring bundle integrity for handling and shipping.

- Bundle Discharge: The completed, tightly strapped bundle is automatically discharged onto conveyors or designated collection areas.

Key Features and Technical Parameters

While specific configurations vary, core features of the FHOPE system often include:

- Automation Level: Fully automatic operation, minimizing manual intervention.

- Control System: Advanced PLC with intuitive Human-Machine Interface (HMI) for parameter setting and monitoring.

- Tube Diameter Range: Customizable to accommodate a wide spectrum of pipe sizes (e.g., handling 30mm OD as demonstrated).

- Bundle Configuration: Standard hexagonal shape for optimal space utilization; other shapes potentially configurable.

- Strapping Unit: Integrated automatic strapping head (PET or steel strap options).

- Construction: Heavy-duty, robust steel frame designed for demanding industrial environments and long service life.

- Safety: Comprehensive safety features, including guarding and emergency stops, compliant with industrial standards.

Tangible Benefits for Steel Processors

Implementing the FHOPE automated bundling line delivers measurable advantages:

- Enhanced Throughput: Significantly increases the speed of the packaging process, boosting overall production capacity.

- Improved Safety: Drastically reduces manual handling requirements, minimizing ergonomic risks and potential injuries.

- Consistent Bundle Quality: Ensures uniform, tightly secured bundles every time, improving load stability and reducing product damage during transit.

- Reduced Labour Costs: Frees up personnel for higher-value tasks, optimizing workforce allocation and lowering operational expenses.

- Streamlined Logistics: Produces standardized, stable bundles ready for efficient storage and transportation.

Industry Applications

This automated bundling and packing technology is crucial for:

- Steel Tube & Pipe Mills

- Metal Service Centers

- Steel Processing Facilities

- High-Volume Distribution Hubs

- Automotive & Construction Material Suppliers

Conclusion: A Strategic Investment in Efficiency

The FHOPE Steel tube bundle making machine and packing line is more than just equipment; it's a strategic investment in operational excellence. By automating a critical, yet often challenging, part of the production process, businesses can achieve significant gains in efficiency, safety, and quality control. As industry reports consistently emphasize the competitive advantages of automation, adopting solutions like FHOPE's positions manufacturers and processors for sustained growth and profitability in a demanding global market.

For more detailed information on how this automated system can be tailored to your specific operational requirements, please contact FHOPE.

Contact: info@fhopepack.com