Automatic Packaging Lines for Steel Tubes & Profiles: Enhancing Efficiency and Precision in Fabrication

In modern steel processing and fabrication environments, efficiency, safety, and consistency are paramount. Manual handling and packaging of steel tubes, pipes, and profiles can be labor-intensive, time-consuming, and prone to inconsistencies and potential product damage. Automatic packaging lines offer a robust solution, streamlining the entire process from finished product to ready-for-shipment bundles. This article delves into the technical aspects, components, operational benefits, and user experience of these essential systems, aligning with the practical focus valued by fabricators.

1. The Bottleneck: Challenges of Manual Steel Tube & Profile Packaging

Traditionally, packaging long or heavy steel products involved significant manual effort:

- Labor Intensity: Requiring multiple workers for counting, aligning, bundling, and wrapping.

- Inconsistency: Bundle shapes, tightness, and protective wrapping can vary significantly.

- Safety Risks: Manual handling of heavy steel sections poses ergonomic and safety hazards.

- Potential Damage: Improper handling can lead to scratches, dents, or deformation.

- Slow Throughput: Manual processes often struggle to keep pace with production output.

2. Automation Solution: The Integrated Steel Packaging Line

An automatic packaging line for steel tubes and profiles is an integrated system designed to automate the handling, counting, bundling, forming (typically into square or hexagonal shapes), and wrapping processes. These systems are engineered to handle a variety of product types, including:

- Square and Rectangular Hollow Sections (HSS)

- Round Tubes and Pipes

- Various Steel Profiles and Sections

The primary goal is to create tightly secured, uniformly shaped, and often protectively wrapped bundles suitable for storage and transport, directly from the production or finishing line.

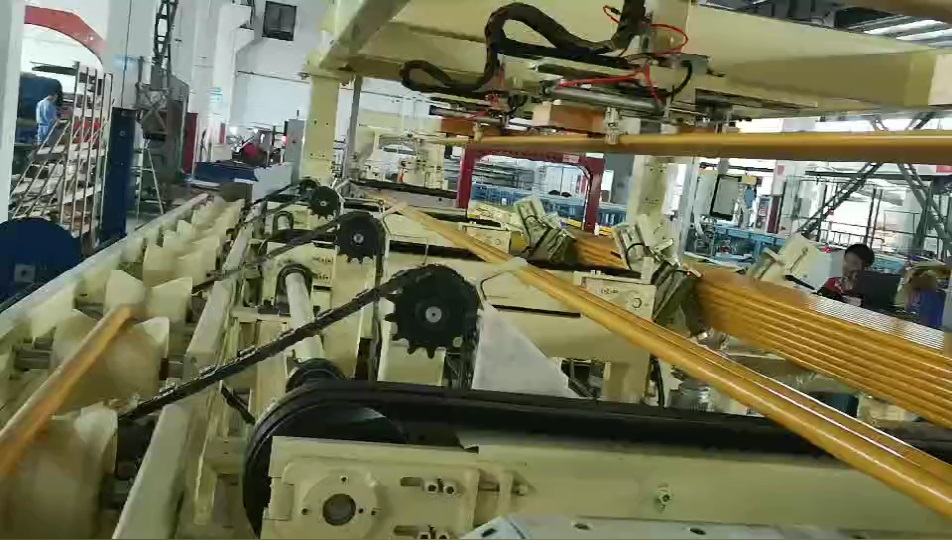

3. Anatomy of the System: Core Components and Functionality

While customizable, most automatic steel packaging lines incorporate several key modules working in sequence:

3.1. Infeed & Counting Systems

Products typically arrive via roller conveyors from the production line. Advanced sensors (photocells, laser counters, or vision systems) accurately count the tubes or profiles required for each bundle layer or the total bundle count, ensuring precision and eliminating manual counting errors.

3.2. Layer Forming & Alignment

Once counted, pieces are systematically arranged into predefined layers. Mechanical pushers, guides, or robotic arms ensure precise alignment, critical for forming stable square or hexagonal bundles later.

3.3. Automatic Bundling (Strapping/Banding)

Robust strapping heads automatically apply, tension, seal, and cut steel or high-strength PET strapping around the formed layers or the completed bundle. The number and position of straps are typically programmable via the Human-Machine Interface (HMI).

3.4. Bundle Shaping (Square/Hexagonal Formation)

Specialized mechanisms, often involving side presses and aligning tools, precisely form the loose collection of tubes/profiles into the desired final bundle shape (e.g., compact square or stable hexagonal) before final strapping or wrapping.

3.5. Wrapping & Protection

For enhanced protection against environmental factors (moisture, dust) and handling abrasion, bundles can pass through an automatic wrapping station. This often involves:

- Stretch Wrapping: Orbital stretch wrappers apply layers of stretch film around the bundle.

- Paper/VCI Application: Systems can integrate the application of protective paper or Volatile Corrosion Inhibitor (VCI) paper/film for rust prevention.

3.6. Weighing & Labeling (Optional Integration)

Integrated weigh scales can capture the precise weight of each bundle, and automatic label applicators can affix identification tags with barcodes, batch numbers, dimensions, and weight data, facilitating inventory management.

3.7. Outfeed & Stacking

Completed bundles are transported via powered conveyors to an accumulation or pick-up area, ready for forklift removal or integration into further automated storage/retrieval systems.

4. Key Technical Specifications & Performance Data

When evaluating an automatic packaging line, consider these critical parameters:

- Product Size Range:

- Dimensions: Specify the minimum/maximum diameter, square/rectangular size (e.g., 20x20mm to 150x150mm).

- Length: Define the operational length range (e.g., 3 meters to 12 meters).

- Bundle Configuration:

- Shape: Square, Hexagonal, Rectangular.

- Max Dimensions: Specify maximum bundle width and height.

- Max Weight: Define the system's maximum bundle weight capacity (e.g., up to 5000 kg).

- Throughput / Cycle Time:

- Typically measured in bundles per hour or seconds per bundle (e.g., 60-120 seconds per bundle, depending on size and complexity).

- Strapping System:

- Type: Steel or PET strapping.

- Strap Size: Compatible strap widths and thicknesses.

- Number of Straps: Programmable.

- Wrapping System (if applicable):

- Film Type: Stretch film specifications.

- Overlap Control: Programmable percentage of overlap.

- Control System:

- Typically PLC-based (e.g., Siemens, Allen-Bradley) with a user-friendly HMI touchscreen for recipe management, diagnostics, and operation.

- Power & Air Requirements:

- Voltage/Frequency/Phase, Estimated Power Consumption (kW), Compressed Air Pressure (bar/psi) and Consumption (L/min).

- Footprint:

- Overall system dimensions (Length x Width x Height) and layout requirements.

Technical Data Comparison (Example Ranges):

| Parameter | Typical Range | High-Capacity Range | Notes |

|---|---|---|---|

| Tube/Profile Size | 20-150 mm | Up to 300 mm+ | Width/Diameter |

| Product Length | 3 - 12 m | Up to 18 m+ | Requires adequate conveyor length |

| Bundle Weight | 500 - 3000 kg | Up to 7000 kg+ | Depends on structure & drive power |

| Cycle Time | 90 - 180 sec/bundle | 45 - 90 sec/bundle | Varies greatly with bundle size/straps |

| Strapping Heads | 1 - 2 | 2 - 4+ | More heads = faster strapping |

| Automation Level | Semi to Full | Fully Integrated | Integration with MES/ERP possible |

5. Design, Structure, and Durability Considerations

Built for demanding industrial environments, these lines emphasize robust construction:

- Frame: Heavy-duty welded steel construction for rigidity and longevity.

- Components: Use of high-quality, wear-resistant materials for rollers, guides, and mechanisms. Reputable component suppliers (motors, gearboxes, pneumatics, sensors) are crucial for reliability.

- Modularity: Modern designs often allow for modular configurations, enabling easier customization, potential future expansion, or integration of specific modules.

- Safety: Comprehensive safety features are essential, including safety fencing, light curtains, emergency stops, and interlocked access doors, complying with relevant safety standards (e.g., ISO, CE).

6. Operational Advantages & Return on Investment (ROI)

Implementing an automatic packaging line delivers tangible benefits for fabricators:

- Increased Throughput: Significantly faster packaging cycles compared to manual methods, aligning packaging speed with production output.

- Reduced Labor Costs: Frees up personnel previously dedicated to manual packaging for higher-value tasks. Often requires only one operator for supervision and material replenishment.

- Improved Consistency: Uniform bundle shapes, strap tension, and wrapping quality enhance load stability and professional appearance.

- Enhanced Worker Safety: Eliminates strenuous manual lifting and handling, reducing the risk of musculoskeletal injuries.

- Minimized Product Damage: Gentle, controlled handling reduces scratches, dings, and deformation compared to manual processes.

- Better Space Utilization: Optimized bundle shapes can improve storage density.

The ROI is typically calculated based on labor savings, increased throughput, reduced product damage, and improved safety records, often resulting in payback periods attractive to cost-conscious operations.

7. User Experience & Implementation Insights

From a user perspective, modern systems offer:

- Ease of Operation: Intuitive HMI touchscreens allow operators to select pre-programmed recipes for different product sizes and bundle configurations, monitor system status, and troubleshoot alarms.

- Maintenance: Designed for durability, but regular preventive maintenance (lubrication, inspection of wear parts, sensor checks) is crucial. Good systems provide easy access to key components.

- Integration: Seamless integration with upstream processes (like cutting or milling lines) and downstream logistics (warehouse management systems) is a key consideration for maximizing overall plant efficiency. Understanding PLC technology provides background on the control systems often used.

- Training & Support: Reliable vendors, like Fhopepack with their noted experience, provide comprehensive training for operators and maintenance staff, along with ongoing technical support and spare parts availability.

8. Selecting the Right Automatic Packaging System

Choosing the optimal line requires careful consideration of:

- Production Volume: Match the system's throughput capacity to your current and projected output.

- Product Mix: Ensure the machine can handle the full range of sizes, shapes, and lengths you process.

- Required Bundle Type: Define whether square, hexagonal, or other shapes are needed, and the level of protection (strapping only, wrapping).

- Budget: Balance initial investment cost against long-term operational savings and ROI.

- Available Space: Assess the required footprint and ensure it fits within your facility layout.

- Level of Automation: Determine the desired degree of integration with other plant systems.

Conclusion: Investing in Automated Packaging Efficiency

Automatic packaging lines for steel tubes and profiles represent a significant step forward from manual methods. By leveraging automation for counting, bundling, shaping, and wrapping, fabricators can achieve substantial improvements in efficiency, consistency, safety, and overall packaging quality. The detailed technical specifications, robust design, and user-friendly operation of modern systems make them a valuable investment for any steel processing facility looking to optimize its end-of-line operations and maintain a competitive edge. Carefully evaluating your specific needs against the capabilities outlined above will guide you towards the most effective automated solution.