Future-Ready Solutions: Scalable Automatic Packing Lines for Growing Steel Coil Demands

The global demand for steel coils continues to surge, driven by growth in key sectors like automotive manufacturing, construction, and appliance production. Meeting this demand efficiently requires robust and automated packaging solutions that not only enhance throughput but also guarantee the integrity of valuable steel products during transit and storage. As documented in numerous industry reports, including findings highlighted in Metal Processing Magazine, inadequate packaging remains a significant contributor to material damage and financial loss in the steel supply chain.

As a specialized manufacturer of automatic coil packing lines, we provide technologically advanced systems engineered to address these critical industry requirements. Our solutions leverage innovations in material science and automation, incorporating design principles potentially drawing from advancements noted in packaging machinery patents focused on tension control and film application efficiency. These lines are designed for scalability and customization, ensuring optimal performance across diverse operational landscapes.

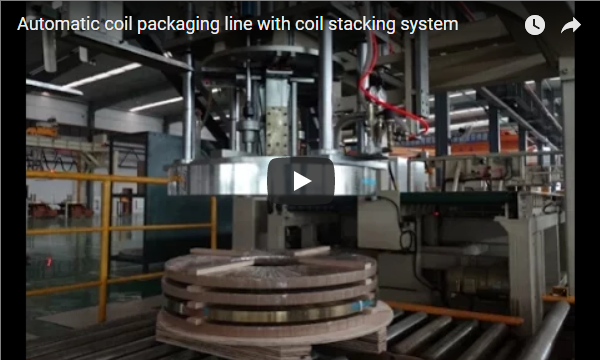

Core Technology: Automated Wrapping and Stacking

Our automatic steel coil packing lines typically integrate several key automated processes:

- Coil Handling: Automated loading and positioning of coils onto the packaging station, minimizing manual intervention and enhancing safety.

- Orbital Wrapping: Precise application of protective films (such as PE, PVC, VCI-infused stretch film) using orbital wrapping technology. This method ensures consistent coverage around the coil's circumference and faces, crucial for barrier protection. Research published in materials science journals consistently underscores the importance of uniform film application in mitigating corrosion risks.

- Stacking Integration: Automated stacking of packaged coils onto pallets or designated storage configurations, optimizing warehouse space and preparing goods for efficient shipment.

- Control Systems: Advanced PLC controls allow for customizable wrapping programs, tension adjustments, and integration with plant-level manufacturing execution systems (MES) or warehouse management systems (WMS) for enhanced traceability and process control.

Key System Parameters & Benefits:

Our systems are configurable to meet specific operational needs. Key parameters often include:

- Coil Outside Diameter (OD): Customizable range, e.g., 800mm - 2200mm

- Coil Inside Diameter (ID): Standard and non-standard sizes accommodated

- Coil Width/Height: e.g., Up to 1000mm

- Coil Weight Capacity: e.g., Up to 5000kg (or specified requirement)

- Wrapping Materials: PE Film, Stretch Film, VCI Film, PVC Film, Paper, Woven Materials

- Throughput Rate: Designed based on cycles per hour requirements

Primary benefits delivered by these automated lines include:

- Enhanced Product Protection: Superior defense against moisture, corrosion, dust, and handling damage, preserving material quality. The use of VCI (Volatile Corrosion Inhibitor) films, often recommended in technical papers on metal preservation, can be seamlessly integrated.

- Increased Operational Efficiency: Significant boost in packaging throughput compared to manual or semi-automatic methods, reducing bottlenecks.

- Labor Optimization & Safety: Reduces manual handling requirements, minimizing ergonomic risks and associated labor costs.

- Material Cost Savings: Precise film application and tension control optimize material usage, reducing waste.

- Consistency & Quality: Ensures uniform packaging quality for every coil, enhancing brand presentation and customer satisfaction.

- Scalability: Modular designs allow for future expansion or modification as production demands evolve.

Industry-Specific Applications:

Automotive Manufacturing:

The automotive industry demands pristine surface quality for steel coils used in body panels and structural components. Our packing lines address this by:

- Handling large-format coils (e.g., up to 2200mm OD).

- Applying protective PE or specialized films with controlled tension to prevent surface marring and contamination, critical for Class A finishes.

- Ensuring robust packaging integrity to withstand the rigors of Just-in-Time (JIT) logistics and frequent handling, a necessity highlighted in automotive supply chain studies.

Construction Sector:

Steel coils for structural elements, roofing, and cladding require durable protection against environmental exposure during transport and on-site storage. Our systems provide:

- Capability to handle heavy coils (e.g., up to 1200kg or significantly more, as specified).

- Application of heavy-duty protective materials like reinforced PVC or woven poly films for enhanced tear resistance and UV protection.

- Secure wrapping that maintains coil shape and stability, crucial for safe handling and preventing damage that could compromise structural integrity, aligning with best practices often cited in construction logistics publications.

Appliance Manufacturing:

Manufacturers of appliances like refrigerators, washing machines, and ovens rely on steel coils with specific aesthetic and functional properties. Our packing solutions ensure:

- Versatility to handle diverse coil dimensions common in appliance component manufacturing.

- Tight, moisture-resistant wrapping using stretch film, often incorporating VCI elements to prevent corrosion during shipping and warehousing – a key concern noted in appliance industry quality standards.

- Protection against scratches, dents, and contamination, preserving the final product's visual appeal and functional quality.

To explore how our advanced automatic coil packing and stacking lines can be tailored to meet the unique challenges and throughput requirements of your specific industry, please contact us.

Contact Information:

Email: info@fhopepack.com

We are dedicated to delivering innovative, reliable, and efficient packaging solutions that safeguard your products and optimize your operations.