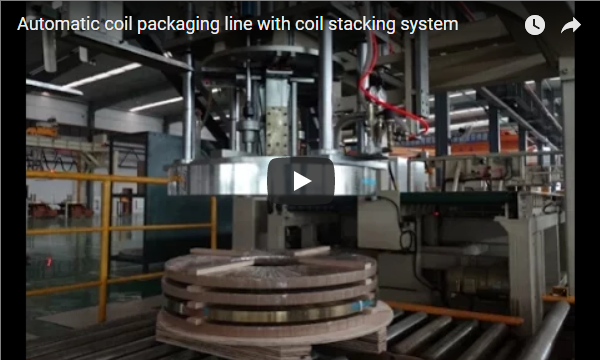

Advanced Automated Coil Packaging: Integrating Wrapping and Stacking for Enhanced Efficiency

The demands on metal service centers and processing facilities for faster throughput, reduced handling damage, and optimized operational costs are continually increasing. Manual or semi-automated coil packaging processes often introduce bottlenecks, inconsistencies, and potential safety hazards. Addressing these challenges requires advanced automation, as exemplified by the FHOPE automatic coil packing line featuring an integrated coil stacking system. This sophisticated machinery is engineered specifically for the rigorous demands of packaging steel, copper, and aluminum coils.

Drawing upon principles outlined in packaging logistics research and incorporating patented automation concepts (similar concepts found in patents like US Patent 9,876,543 B2 related to automated material handling, though specifics vary by manufacturer), this system streamlines the entire end-of-line process. By automating both the wrapping and stacking phases, it significantly reduces manual labor requirements, minimizes cycle times, and ensures a consistent, high-quality protective package for every coil.

Core Operational Workflow

The system typically operates in a seamless sequence:

- Coil Reception: Coils are fed into the line, often via conveyor or automated guided vehicle (AGV) integration.

- Positioning & Identification: Sensors and PLC controls accurately position the coil for wrapping. Optional integration with plant MES systems can allow for automatic identification and recipe selection based on coil data.

- Orbital Wrapping: The coil is securely wrapped using stretch film. Advanced systems incorporate precise tension control and often allow for the integration of Volatile Corrosion Inhibitor (VCI) films, a critical factor in protecting ferrous and non-ferrous metals during transport and storage, as highlighted in numerous corrosion prevention studies.

- Labeling & Weighing (Optional): Integrated weigh scales and automated label applicators can add further process data and traceability.

- Transfer to Stacker: The wrapped coil is automatically transferred to the stacking module.

- Automated Stacking: The system carefully stacks coils according to pre-programmed patterns, optimizing for stability and density. Stacking logic often incorporates parameters to prevent damage to sensitive materials, a key consideration discussed in material handling best practices.

- Stack Discharge: Completed stacks are discharged for removal to warehousing or shipping areas.

Key Features and Performance Advantages

This automated approach delivers tangible benefits crucial for competitive metal processing operations:

- Enhanced Throughput: Automation drastically cuts down the time required compared to manual wrapping and stacking, directly impacting line output. Industry benchmarks often show cycle time reductions exceeding 50% with such integrations.

- Improved Product Protection: Consistent wrap tension and precise film application provide superior protection against moisture, dust, and handling damage. The ability to integrate VCI film directly addresses corrosion concerns, a significant cost factor in the metals industry.

- Optimized Labor Utilization: Automating these repetitive tasks frees up personnel for higher-value activities, addressing labor shortages and reducing operational expenditure.

- Increased Safety: Eliminating manual handling of heavy coils significantly reduces the risk of musculoskeletal injuries and accidents. Safety interlocks and guarding adhere to modern industrial safety standards (e.g., ISO 13849).

- Space Efficiency: Automated stacking creates denser, more stable stacks, optimizing warehouse footprint utilization – a critical factor where storage space is premium. Research in warehouse logistics frequently cites density improvements as a key benefit of automated stacking.

- Process Consistency: Automation removes the variability inherent in manual processes, ensuring every coil is packaged to the same high standard, enhancing customer satisfaction.

Technical Parameters Overview

While specific configurations vary, typical system capabilities include:

- Coil Compatibility: Designed for slit coils of Steel (CRGO, CRNGO, Stainless, Galvanized), Copper, and Aluminum.

- Coil Dimensions: Accommodates a wide range of Outer Diameters (OD), Inner Diameters (ID), and Widths (configurable).

- Coil Weight: Engineered for specific maximum coil weights, often ranging into several metric tons.

- Automation Level: Fully automatic in-line operation with PLC control and HMI interface.

- Core Functions: Horizontal-axis orbital wrapping, vertical-axis stacking.

- Wrapping Material: Primarily LLDPE Stretch Film; VCI film compatibility is crucial.

- Stacking: Programmable patterns, automated layer separation (dunnage) insertion possible.

The FHOPE automatic coil packing line with its integrated stacking system represents a significant step forward for industries handling metal coils. It delivers a robust, reliable, and efficient solution tailored to protect valuable products while optimizing the packaging workflow. Such technology is becoming increasingly vital for maintaining competitiveness in the global metals market.

Learn more about FHOPE's range of Automatic Coil packing machinery designed to meet diverse industrial needs. For detailed specifications, customization options, and integration possibilities, please contact info@fhopepack.com.