Mastering Small ID Bearing Packaging: Advanced Eye-Through Wrapping Solutions

Packaging bearings, particularly those with small inner diameters (IDs) – often below 200mm – presents unique challenges for manufacturers and logistics operations. Standard wrapping techniques may struggle with the tight clearances, demanding specialized . Ensuring adequate protection against corrosion, contamination, and physical damage during storage and transit is paramount, yet achieving this efficiently with small bore bearings requires precision-engineered solutions.

Difficulties arise primarily from the physical constraints: the wrapping mechanism, carrying the protective material (like VCI film, stretch wrap, or paper), must pass cleanly through the bearing's central opening, or eye. This necessitates a wrapping ring or shuttle with a minimal profile, leaving sufficient safety margins to prevent contact and potential damage to sensitive bearing surfaces. Furthermore, applying various packaging materials, sometimes in multiple layers, adds complexity. Industry publications like Packaging Digest often highlight the need for adaptable machinery in handling diverse product geometries.

FHOPEPACK has developed proven automated solutions specifically addressing the intricacies of small ID bearing packaging. These systems are engineered to navigate minimal clearances while ensuring consistent, high-quality wrapping.

Key Considerations in Eye-Through Wrapping for Small Bearings

Successfully implementing eye-through wrapping hinges on several critical factors:

- Wrapping Ring / Shuttle Size: The core challenge. The outer dimension of the ring, including the loaded packing material, must be smaller than the bearing's minimum ID. Innovations in compact wrapping head design, sometimes drawing from principles in patents focusing on miniaturized drive systems (e.g., exploring concepts related to USPTO filings on compact annular mechanisms), are crucial.

- Clearance and Safety: Adequate space must be maintained between the wrapping apparatus (ring + material) and the bearing's inner raceway during the wrapping cycle. Insufficient clearance risks costly collisions and product damage. Advanced sensor technology and precision control systems are vital, a topic frequently discussed in Control Engineering regarding automated systems.

- Material Handling & Application: Different materials like VCI paper, stretch film, or barrier films have unique properties. The system must reliably feed, tension, and cut these materials within the confined space of the bearing bore. Research in Polymer Engineering & Science often delves into the optimal tensile and elongation properties of films for such demanding wrapping applications.

FHOPEPACK Automated Solutions for Small ID Bearing Packaging

As a manufacturer addressing these specific needs, FHOPEPACK offers tailored machinery based on bearing dimensions.

Machine Option 1: FPCA-100 - Optimized for Ultra-Small Bores (ID: 100-130mm)

This model is specifically engineered for bearings at the smallest end of the ID spectrum where clearance is most critical.

- Design Principle: Features a design where the packing material roll is fixed directly onto the rotating wrapping ring. This minimizes the overall profile passing through the bearing eye.

- Target Bearing ID: 100mm - 130mm

- Packing Material: Typically utilizes narrower rolls suited for the compact ring.

- Applied Material Width: ~40mm

- Material Roll OD: ~50-70mm

Video Demonstration (Note: Showing cable coil, applicable to similar sized bearings):

Operational Note: This integrated material approach is a common engineering solution when dealing with extremely restricted access, ensuring the material follows the ring's path precisely.

Machine Option 2: FPCA-200 - Versatility for Small to Medium Bores (ID: 130-200mm)

Offering more flexibility for slightly larger, yet still challenging, bearing IDs.

- Target Bearing ID: 130mm - 200mm

Version 2.1: Ring-Mounted Material Configuration

Similar in principle to the FPCA-100, this version maintains the compact design by mounting the material roll on the ring.

- Design Principle: Packing material fixed on the wrapping ring.

- Packing Material Specs:

- Applied Material Width: ~50mm

- Material Roll OD: ~60-100mm

Video Demonstration:

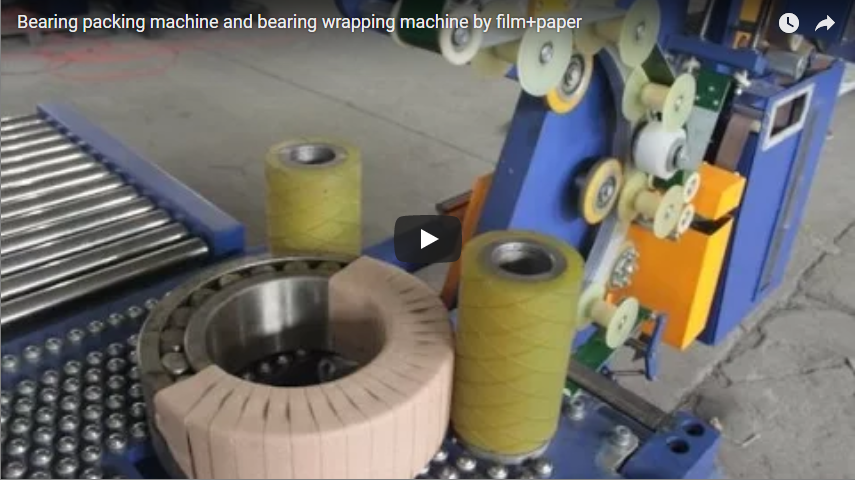

Version 2.2: External Material Feed Configuration

This configuration separates the material roll holder from the wrapping ring, locating it adjacent to the main machine frame.

- Design Principle: Packing material roll(s) are positioned externally, feeding material to the wrapping ring/shuttle.

- Key Advantage: Allows for potentially larger material rolls, reducing changeover frequency. Critically, it facilitates the application of multiple packaging material types sequentially (e.g., VCI paper followed by stretch film) within a single automated cycle. This multi-layer approach is often recommended in industry best practices (similar to guidelines from bearing manufacturers like SKF or Timken) for comprehensive protection.

Video Demonstration (Multi-Material Application):

Operational Note: This version enhances operational flexibility and efficiency, particularly for processes requiring layered protection against both corrosion (VCI) and physical/environmental factors (stretch film).

The Bottom Line: Precision Packaging for Demanding Applications

Automating the packaging of small ID bearings requires more than just standard wrapping equipment. It demands machinery specifically designed to navigate tight clearances safely and apply protective materials effectively. Solutions like FHOPEPACK's FPCA-100 and FPCA-200 series address these unique challenges, offering configurations tailored to specific ID ranges and material requirements, ultimately contributing to product integrity and operational efficiency. Ensuring bearings reach their destination in optimal condition often starts with investing in the right, specialized packaging technology.

For manufacturers seeking robust solutions for challenging bearing packaging applications, exploring specialized machinery like the FPCA series is crucial. Further details on FHOPEPACK's comprehensive range of bearing packing machines can be found here: https://www.fhopepack.com/Bearing-packing-machine/