One such innovative solution is the Door and Panel Bubble Film Packing Machine, specifically designed to protect fragile and sensitive products such as doors, panels, and glass sheets. In this article, we provide an in-depth analysis of how this packing machine operates, highlighting its key features, benefits, and potential applications.

The Door and Panel Bubble Film Packing Machine is a fully automated system that ensures the secure and precise wrapping of doors and panels with bubble film. The machine utilizes advanced technology and engineering principles to achieve optimal performance and adaptability in various industrial settings.

The operation begins by feeding the door or panel onto a conveyor system, which transports the product to the wrapping zone. Here, the machine automatically measures the dimensions of the incoming product, ensuring accurate and consistent wrapping. This feature not only saves time but also minimizes material waste and guarantees that each product receives the proper protection.

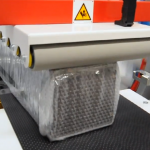

Next, the machine applies a layer of bubble film to the product’s surface. The film is unwound from a roll and stretched over the door or panel using a series of rollers and tensioning mechanisms. This process ensures that the bubble film is tightly wrapped around the product, providing maximum cushioning and protection against potential impacts and scratches during transport or storage.

Once the bubble film is in place, a heat-sealing mechanism cuts and seals the film’s edges, securely enclosing the product. This step further enhances the protection offered by the packing machine, as it prevents the bubble film from shifting or detaching during handling.

The packed product then moves along the conveyor system, where it may be subjected to additional packaging processes, such as strapping or labeling, before being transported to the storage or shipping area.