This is a video for Steel coil manual packaging process.

The process of manually packaging steel coils involves a series of steps designed to safeguard and secure the coils during their storage and transportation. Initially, a layer of polyethylene (PE) film is applied to shield the steel surfaces from moisture, dust, and potential contaminants. Following this, an anti-corrosion paper layer is added to prevent corrosion resulting from environmental factors. To ensure stability, radial strapping is employed by placing straps in a radial arrangement around the coil. This helps prevent any shifting or displacement. Additionally, circumferential strapping is used to reinforce the radial strapping, thereby enhancing overall strength and stability. Through these meticulous packaging procedures, the integrity and quality of the steel coils are effectively protected, minimizing the risk of damage, corrosion, or displacement. By adhering to this packaging process, the coils remain well-protected throughout their entire journey, from the manufacturing stage to their final destination.

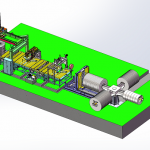

FHOPE manufacture automatic packaging machines that can achieve the same packaging results while reducing packaging time. It can greatly improve the packing efficiency and reduce the labor cost.

For more details, feel free to contact info@fhopepack.com.