This is video for panel bag packing machine

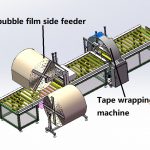

A panel bag packing machine is specifically engineered for enclosing flat or relatively flat products, such as panels, in protective plastic bags. This sophisticated machinery usually consists of a feeding conveyor, a bagging area where the panel is automatically positioned into the bag, and a sealing device that seals the bag once the panel is inside. The structure of the machine is designed to handle various panel sizes and bag materials, ensuring a tight fit and secure packaging, critical for protecting the contents during storage and transportation.

The parameters below do not 100% match the equipment in the video. For exact specifications, please contact us.

- Type: Fully Automatic

- Year of Manufacture: 2023

- Condition: New

- Maximum Packing Size: Length: 2000mm; Width: 1200mm

- Packing Speed: Up to 15 bags per minute

- Bag Material Compatibility: Polyethylene, Bubble Wrap, Antistatic bags

- Power Requirements: 220V, 50Hz, single phase

- Machine Dimensions: Length: 3200mm; Width: 2400mm; Height: 2100mm

- Machine Weight: Approximately 800kg

- Warranty: 2 years

- Origin: Made in Taiwan

- Control System: PLC with touchscreen interface

- Sealing Method: Heat sealing

- Additional Features: Adjustable bag size, automatic panel alignment

Applications for the panel bag packing machine:

- Electronics Industry: Precision Packaging

The panel bag packing machine is ideal for the electronics industry, where sensitive components like circuit boards require precise and secure packaging. With the capacity to handle panel sizes up to 2000mm by 1200mm, and compatibility with antistatic bags, this machine ensures electronics are protected from static and mechanical damage. The automated alignment and heat sealing provide a secure enclosure, significantly reducing the risk of shipping damages. - Furniture Manufacturing: Efficient Wrap and Seal

In furniture manufacturing, large, flat panel components such as tabletops and shelves can be quickly and efficiently packed using this machine. Its ability to process up to 15 bags per minute enhances productivity and helps manufacturers keep pace with high production demands. The machine’s capability to adjust to different bag sizes ensures that each piece is wrapped securely, minimizing surface damage and improving customer satisfaction upon product delivery. - Printing and Signage: Tailored Protective Packaging

The panel bag packing machine also serves the printing and signage industry, where protecting large printed materials and signs during transit is crucial. The adjustable bag size feature allows for custom packaging of variously sized prints, ensuring that items such as billboards, posters, and digital prints are shielded from moisture, dust, and abrasion. This application ensures that the visual quality of printed materials is maintained from warehouse to final installation, providing a significant advantage in maintaining print integrity and appearance.