|  |

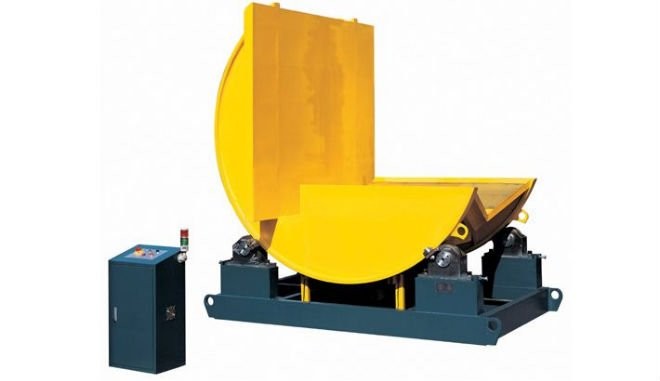

Mould Tilter & Upender | Coil Tilter& Upender |

|  |

Coil Upender/tilter | Spool/Drum Tilter |

|

|

Hydraulic Upender/Tilter | Load Inverters |

The new-technology FHOPE additionally adaptable chain conveyor makes use of optimized sliding characteristics for the chains and slide rails, fewer joints with minimal-friction components, gliding surfaces that do not demand machining, and link technology engineered for simple assembly and modification.

FHOPE additionally is provided in monitor widths ranging from 65 mm to 320 mm, with standard, in-inventory supplies such as 45-deg and 90-deg curve sections. In the lite-F, vacant containers are indexed into one end of the machine and transported on the conveyor to the filling heads. Right after filling, they are then transported to a discharge stage.

The main problem the WRAP group confronted was fitting the hydraulic tilter furthermore into the present lite-F style, which was practically all set for fabricating and was scheduled to debut at a significant trade show in much less than a few months’ time. This needed the development of two custom made curves, a single with a seven-deg angle and an additional with a 15-deg angle and modified/customized link details with longer infeed and discharge sections to match the conveyor’s closed-loop about the filling station equipment.

The conveyor accommodates the lite-F’s maximum container size—up to a hundred and twenty-mm lengthy x one hundred-mm wide—as nicely as transports containers immediately on the belt or relocating “pucks” that contain numerous containers.

“We knew it was a custom design,” Gozlan says. “But we could see that we could sit down and function with Bosch Rexroth to get a much more customized solution, without incurring substantial extra fees.

“We’re glad that we discovered a spouse willing to work with us to develop our requirements more, which was one thing Rexroth’s opponents weren’t as inclined to do.”

1 important instrument that aided the team in assembly the restricted deadlines was Wrap’s packpro computer software. The Home windows-based mostly system for designing and configuring conveyor methods is user-helpful and simple to find out, lets customers merge catalog parts to form assemblies and methods in a digital 3D structure, with assistance of a developed-in rule engine to ensure the remedy will function in the actual globe.

“We utilized MTpro to brainstorm with Groninger on how to use VarioFlow plus,” Schiedeck states. “Immediately it aided us decide that an initial component style would not function, and so with MTpro we were able to quickly function out an substitute set of components to solve the obstacle.”

Important benefits

Among the crucial benefits VarioFlow furthermore and the lite-F device offer Groninger are the adhering to:

• Compact size that fits the needs of the machine’s target marketplaces by retaining the all round machine’s footprint down for the smaller sized non-public-label companies with limited plant floorspace.

• VarioFlow plus’s easy assembly and interchangeable design functions allow companies to modify or broaden their footprint in the future. The modular design and style permits connecting the lite-F to upstream or downstream machines, which assists stop users seeking to increase their potential automation level.

This will allow the hydraulic tilter furthermore to convey stuffed bottles from the lite-F to a bottle-capping device that Groninger plans to deploy in the close to future.

• Easy movement. This is essential in conveying containers, specifically in filling sequences where there are stop-and-begin sequences of motion.

States Gozlan, “The way the VarioFlow plus functions, the link factors are a lot cleaner and smoother running than the competition’s, and that gave us confidence that it would provide the easy movement we need.”

A new partnership ABOUT hydraulic tilter

The two businesses are happy with their partnership’s results. “When you do something custom made, as we have been performing with the unique angles that we needed with the hydraulic tilter plus, you expect that cost could be significantly higher,” Gozlan states. “However, what pleased us at FHOPE was that, when all was said and carried out and the components ordered, it still finished up costing less than the competitor’s remedy.” fhope has currently ordered a second VarioFlow furthermore conveyor and plans to consider such as it in long term machine designs.