info@fhopepack.com

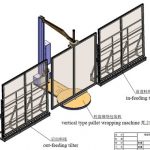

horizontal orbital wrapper for motor on tray

The video is the horizontal orbital wrapper for motor on tray.

It is able wrapping the different product for strapping and tightening the package.

In the wrapping, we can provide packing both packig solution with or without tray.

• Horizontal orientation – The wrapping machine is oriented horizontally, with the tray conveyed into the wrapper on an infeed conveyor.

• Orbital wrapping arm – The arm rotates in an orbital motion around the motor and tray to apply the stretch film. It is typically powered by an electric motor or hydraulic cylinder.

• Film carriage – Holds the roll of stretch film and moves side to side on guide rails to adjust the wrapping width for different tray sizes.

• Unwind system – Feeds the stretch film from the roll to the wrapping arm. Consists of tensioners, idlers and drive rollers to control the film tension.

• Film cutter – Uses a blade to cut the stretch film after completing a wrap.

• Safety features – Like light curtains at the infeed and outfeed, guards over moving parts and emergency stop buttons.

• Hygienic design – Sealed bearings, smooth surfaces, and washdown-rated components to facilitate cleaning.

• Control panel – Contains buttons to operate machine functions like start, stop, speed adjustment, film feed etc.

• Suitable for wrapping medium to large sized motors mounted on trays or skids.

• Provides tamper evidence and protection during shipment and storage.

• Consistent, high-quality wraps due to servo control of the orbital wrapping arm.

• The horizontal orientation allows the tray to be conveyed directly into the wrapper on an infeed conveyor, for easy loading and unloading.

• The orbital wrapping arm applies the stretch film in an over-under pattern as it rotates around the motor and tray. This ensures complete coverage and a secure wrap.

• The wrapping arm speed and rotation pattern can often be programmed to accommodate different tray sizes and shapes.

• The film carriage uses side guide rails to move the carriage left and right. This adjusts the wrapping width to match the tray width for a snug wrap.