Optimizing Wire Coil Packaging: A Guide to Wrapping Machines for Galvanized and Aluminum Wire

Properly packaging wire coils, especially galvanized steel and aluminum wire, is crucial for protecting product integrity during handling, storage, and transportation. Damage from moisture, physical impact, or unwinding can lead to material waste and operational delays. Wire coil wrapping machines offer a specialized packaging solution designed to provide efficient, reliable protection.

Understanding the Role of Wire Coil Wrapping Machines

A wire coil wrapping machine automates the process of applying protective materials around wire coils. This equipment is engineered to handle the unique shape and weight of coils, ensuring consistent and secure packaging.

Core Operational Principles

Most wire coil wrapping machines operate on a similar principle:

- Loading: The wire coil is placed onto a turntable or conveying system.

- Wrapping: The machine dispenses a packaging material (like stretch film or VCI paper) from a carriage that typically orbits around or through the eye of the coil as the coil itself rotates.

- Securing: The film or paper is stretched and applied tightly, overlapping layers to create a stable and protective cocoon around the coil.

- Cutting & Unloading: Once the wrapping cycle is complete, the material is automatically cut, and the wrapped coil can be unloaded.

Key Packaging Materials Utilized

These machines can utilize various materials, each offering distinct advantages:

- Stretch Film: Provides excellent load stability, dust protection, and moisture resistance. It conforms tightly to the coil's shape.

- VCI (Volatile Corrosion Inhibitor) Film/Paper: Contains chemicals that vaporize and form a protective layer on the metal surface, preventing rust and corrosion, particularly important for galvanized steel during long storage or sea transport.

- Paper (Kraft or Crepe): Offers basic protection against scratches and dust, often used in conjunction with other materials or for specific handling requirements.

automatic steel wire coil packing machine1 Benefits of Implementing Automated Wire Coil Wrapping

Integrating a wire coil wrapping machine into your packaging line yields several operational advantages:

- Enhanced Product Protection: Secure wrapping minimizes damage from shifting during transit and protects against environmental factors like dust and moisture. The use of VCI materials specifically guards against corrosion.

- Improved Operational Efficiency: Automated wrapping significantly increases throughput compared to manual methods, reducing bottlenecks and freeing up labor for other tasks. Machines can operate in semi-automatic or fully automatic modes.

- Reduced Labor Costs: Automation decreases the manual labor required for the repetitive task of wrapping coils.

- Optimized Material Usage: Machines apply film or paper with consistent tension and overlap, often using less material than manual wrapping while ensuring better containment.

- Increased Safety: Automating the wrapping process reduces manual handling of heavy coils and repetitive motions for workers.

- Professional Package Appearance: Consistently wrapped coils present a more professional image and can improve handling ease throughout the supply chain.

Wrapping Solutions for Diverse Coil Sizes

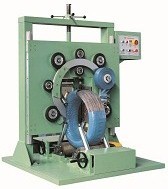

Wire wrapping machines are available for various applications, including securing smaller coiled objects like springs, tubing bundles, or smaller wire spools. These specialized machines often feed a binding wire or strap around the object as it rotates, creating a tight spiral wrap that maintains the coil's shape and prevents unraveling during handling.

Watch this example of a machine packaging smaller coil objects:

Considerations for Selecting Wire Coil Wrapping Equipment

Choosing the right machine depends on several factors:

- Coil Dimensions & Weight: Ensure the machine's capacity matches your product range (inner diameter, outer diameter, width, weight).

- Throughput Requirements: Match the machine's speed (coils per hour) to your production output.

- Level of Automation: Decide between semi-automatic (operator initiates cycle) or fully automatic (integrated into a conveyor line).

- Packaging Material Needs: Verify compatibility with the required materials (stretch film, VCI, paper).

Available Wire Coil Wrapping Machinery Options

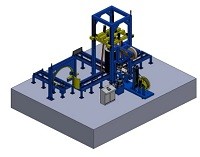

Below are examples of different wire coil wrapping machine configurations designed for various coil sizes and applications.

Conclusion

Wire coil wrapping machines are essential tools for manufacturers and processors dealing with galvanized wire, aluminum wire, and other coiled metal products. By providing robust protection, enhancing packaging speed, and optimizing material use, these machines contribute significantly to efficient operations and ensure products reach their destination in optimal condition. Selecting the appropriate machine based on specific operational needs is key to maximizing these benefits.

.jpg)