info@fhopepack.com www.fhopepack.com

Fhopepack offers whole coil packaging systems. We are professional at strapping, wrapping and film sealing of machines and materials industries. Fhope offering will not only provide you extremely high quality packaging materials but also a kind of art technology,in order to fulfill our goal that ensuring the manufacturers could enjoy responsible, reliable, efficient skill with the lowest cost. At the same time, we are offering has a full range of manual, electricity, and pneumatic packaging equipment, so that you could make a proper choice between them based on your own requirement. To make sure the goods will be safe throughout all the supply chain, we provide the best combination of good quality steel or superior strength and elongation PP/PET strap.

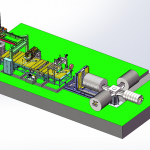

Slit steel coil strip wrapping machines make efficient work of transforming oversized steel coil strips into neatly packaged, narrower coils ready for subsequent manufacturing processes. They automate what would otherwise be a time-consuming and labour-intensive manual procedure.

_Precision Wrapping of Narrow Coils _

The heart of the machine, the wrapping section, utilizes a winding mandrel, tensioning rollers and a wrapping arm to expertly coil up the narrow strips. The tension rollers maintain an optimum degree of tension for tight, even coils without deformation. The wrapping arm moves in synchronization to create well-packed coils of the desired diameter between 200mm to 1000mm.

Programmable Control for Flexibility

An intuitive touch screen interface and programmable logic controller (PLC) enable the operator to input different job parameters and material specifications with ease. settings like slitting width, coil width, wrapping tension and speed can be saved into multiple programs for quick job changeover.

_Consistent Quality and Safety _

Quick change tooling lets you switch between different slitting widths in minutes. Safety guards and interlocks protect operators from any moving parts. Finished coils exit the machine with superior consistency in size, shape and quality for downstream applications.

Slit steel coil strip wrapping machines transform oversized coils into a manageable intermediate product, streamlining your steel handling and boosting production efficiency.