How to Choose an Injection Mold Flipper?

If you’re in the manufacturing industry, then you know the importance of having the right equipment to optimize your operations. One such piece of equipment is the Injection Mold Flipper, which is used for flipping injection molds in the manufacturing process. In this article, we’ll discuss what an Injection Mold Flipper is, the benefits of using one, and what you should consider when choosing a manufacturer.

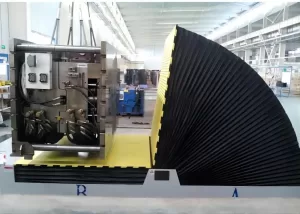

Injection mold flipper table

An injection mold flipper table is a device that rotates an injection mold by 90 degrees for easy access and maintenance. It saves time, manpower and operator’s fatigue. Different types of injection mold tables have different features and functions, such as ergonomic tables and service tables.

90 Degree Injection mold flipper upender

A 90 degree upender injection mold flipper is a machine used to flip injection molds at a 90 degree angle. This machine is commonly used in the manufacturing industry to improve efficiency and reduce production time. By flipping the molds, it allows for easier access to both sides of the mold, which can increase the speed and accuracy of the molding process.

What is an Injection Mold Flipper?

An Injection Mold Flipper is a machine that is used to flip injection molds during the manufacturing process. It is an essential piece of equipment for companies that produce plastic products, as it helps to ensure that the molds are properly aligned and that the finished products are of the highest quality. The Injection Mold Flipper is designed to handle large, heavy molds, and it can be operated manually or automatically depending on the specific needs of the manufacturing process.

There are several different types of Injection Mold Flippers available on the market today. These include manual, semi-automatic, and fully automatic machines. Manual machines are the most basic type of Injection Mold Flipper and require an operator to physically flip the mold. Semi-automatic machines use a combination of manual and automatic processes to flip the mold, while fully automatic machines are completely automated and require no human intervention.

What are the Benefits of Using an Injection Mold Flipper?

The benefits of using an Injection Mold Flipper are numerous. First and foremost, it helps to improve the quality of the finished products. By ensuring that the molds are properly aligned, the Injection Mold Flipper helps to prevent defects and other quality issues that can arise during the manufacturing process. This, in turn, helps to reduce waste and improve efficiency.

In addition to improving product quality, an Injection Mold Flipper can also help to reduce labor costs. By automating the flipping process, companies can reduce the number of workers required to operate the machinery, which can result in significant cost savings over time.

Finally, an Injection Mold Flipper can also help to improve the overall safety of the manufacturing process. By reducing the need for manual labor, it helps to minimize the risk of accidents and injuries, creating a safer work environment for everyone involved.

What are the Important Points to Consider When Choosing a Mold Flipper Manufacturer?

When selecting a manufacturer for your Injection Mold Flipper, there are several important points to consider. First, you should look for a manufacturer with a proven track record of quality and reliability. This can be achieved by researching the manufacturer’s reputation, reading reviews from other customers, and asking for references.

Second, you should consider the specific needs of your manufacturing process. This includes the size and weight of your molds, as well as the level of automation required. Make sure that the manufacturer you choose has experience working with molds of similar size and weight to ensure that they can provide a machine that meets your needs.

Third, you should consider the level of customer support offered by the manufacturer. Look for a company that offers comprehensive support, including installation, training, and ongoing maintenance and repair services. This will help to ensure that your Injection Mold Flipper is always functioning at its best and that any issues can be addressed quickly and efficiently.

Finally, you should consider the cost of the Injection Mold Flipper. While it may be tempting to choose the cheapest option available, it’s important to remember that quality and reliability are more important than price. Look for a machine that offers a good balance of features, performance, and affordability to ensure that you get the best value for your investment.

Conclusion for the injection mold flipper from Manufacturer

In summary, an Injection Mold Flipper is an essential piece of equipment for any company in the manufacturing industry. By improving product quality, reducing labor costs, and increasing safety, an Injection Mold Flipper can help to optimize your operations and improve your bottom line. When choosing a manufacturer for your Injection Mold Flipper, make sure to consider their reputation, experience, and level of customer support to ensure that you get the best machine for your needs.

More mold upender: https://www.fhopepack.com/mold-upender.html