Welcome to our gallery showcasing over 100+ different Upender & Tilter!

Our collection features a wide range of machines designed to meet the diverse needs of various industries.

Explore our gallery today to find the perfect Upender & Tilter for your needs. We’re confident that you’ll find a machine that meets your requirements and exceeds your expectations.

1. Introduction

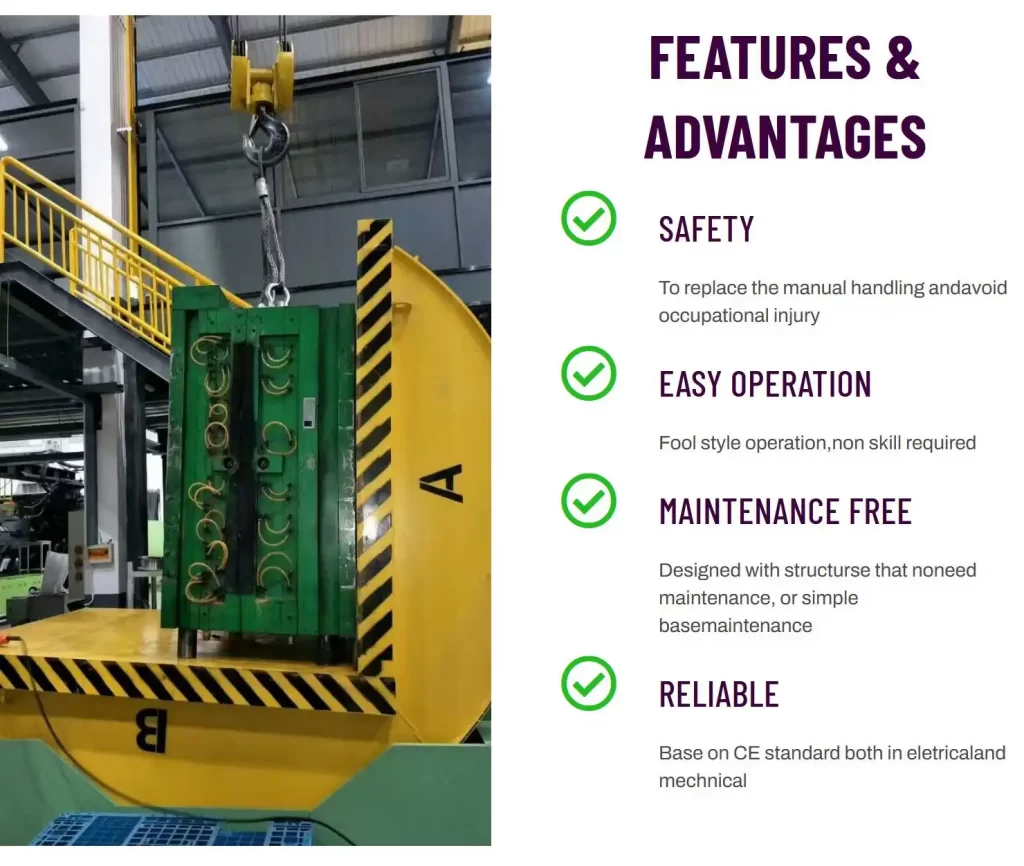

Upenders and tilters, critical machinery in numerous industrial scenarios, enable the secure and effective relocation and orientation of substantial loads.

The escalating need for these devices underscores the importance of opting for a trustworthy and skilled manufacturer to assure top-tier quality and operational excellence..

In this article, we will introduce a leading upender and tilter manufacturer with over 100 image galleries showcasing their expertise and experience in the industry.

About FHOPE Expertise and Experience

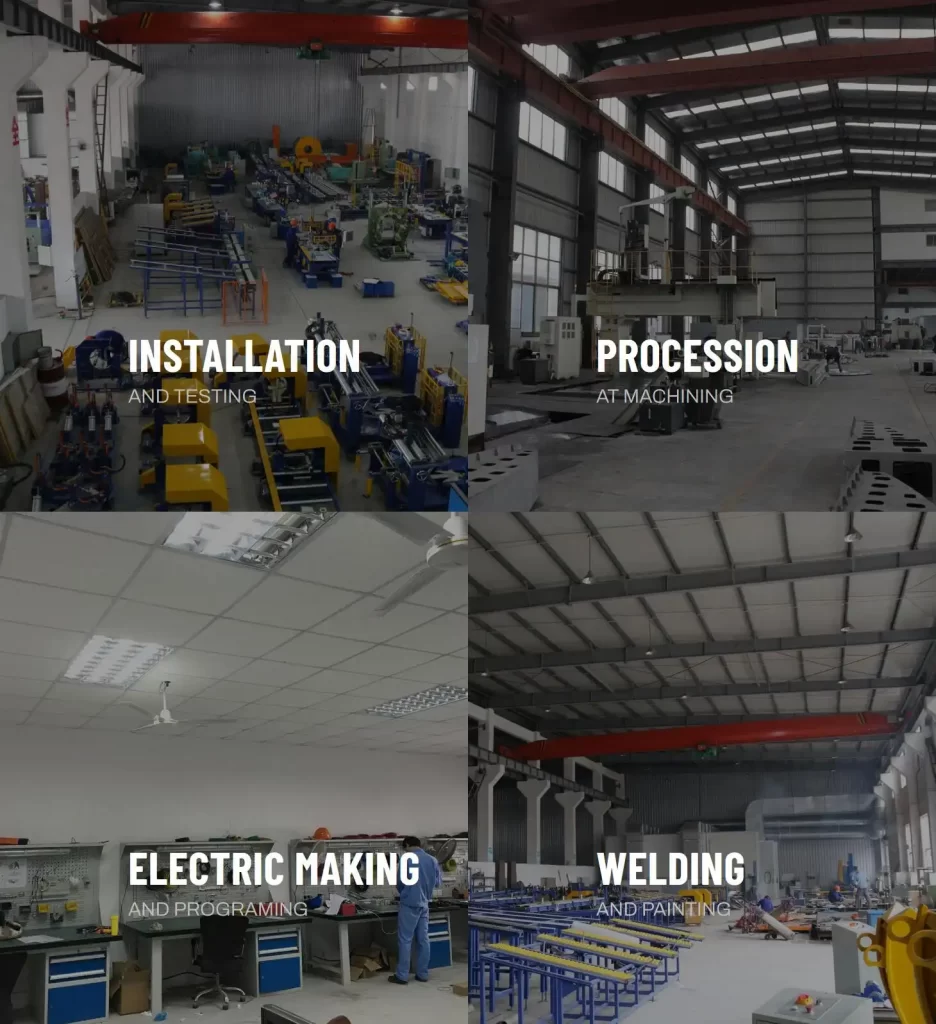

Having accumulated years of expertise in the design and production of upenders and tilters, FHOPE has become renowned for delivering top-notch equipment that caters to various industry needs.

They excel in crafting bespoke solutions, by thoroughly understanding their clients’ distinctive requisites and formulating customized solutions that perfectly align with their individual demands.

2. Products:

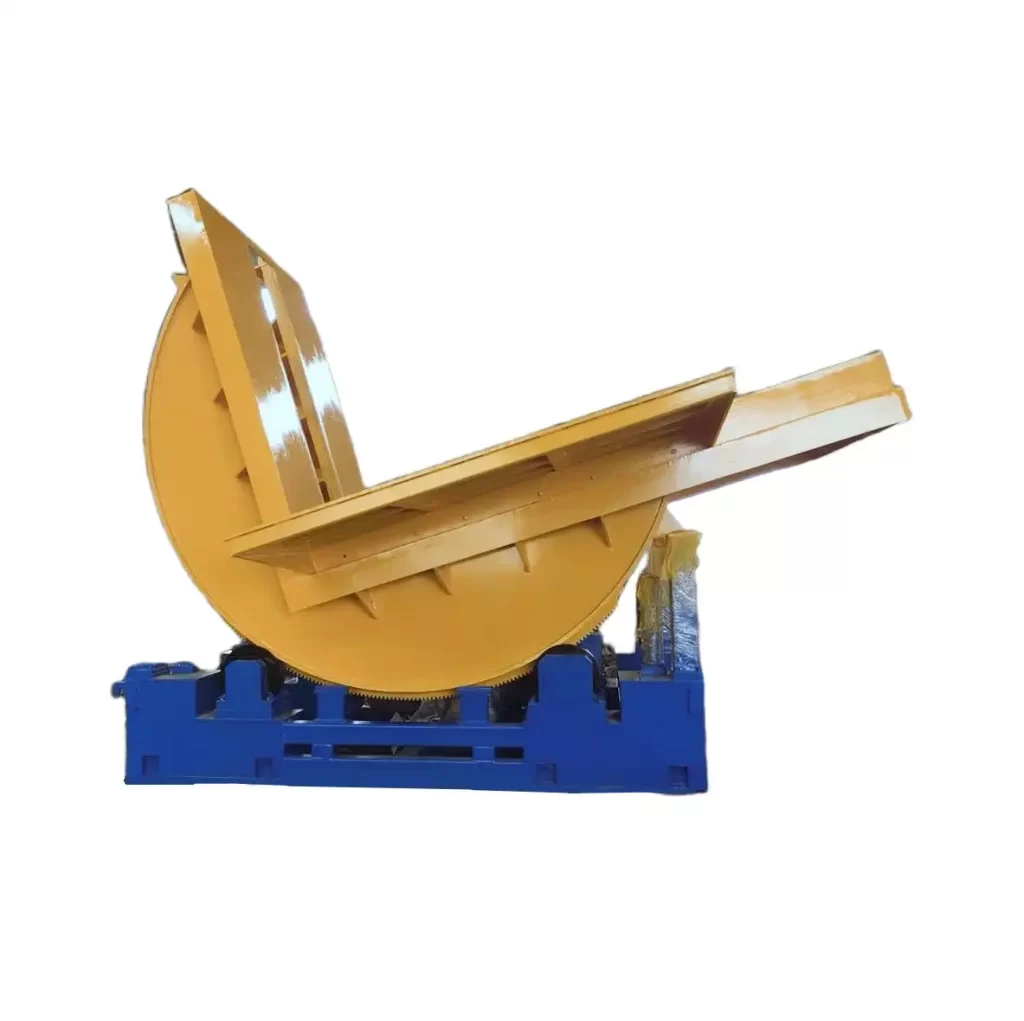

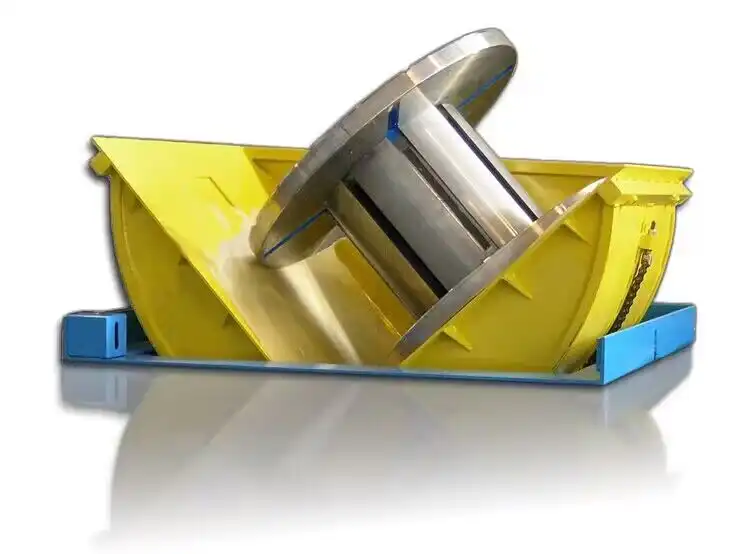

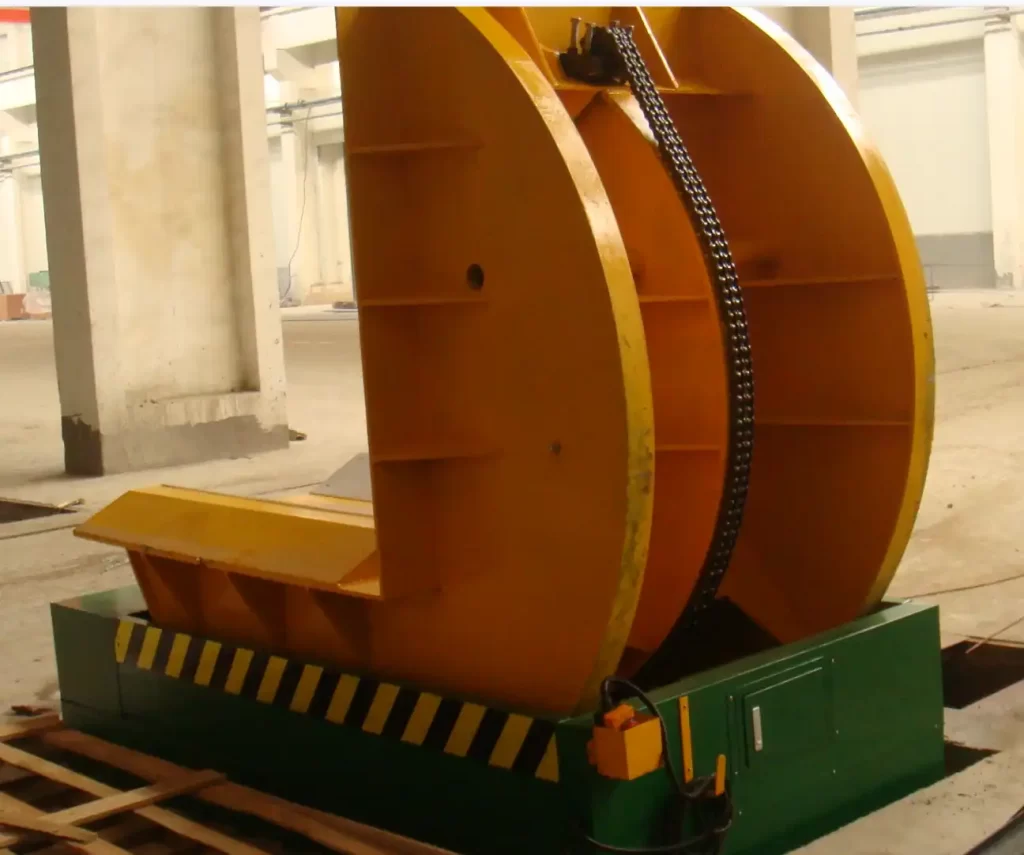

Upenders

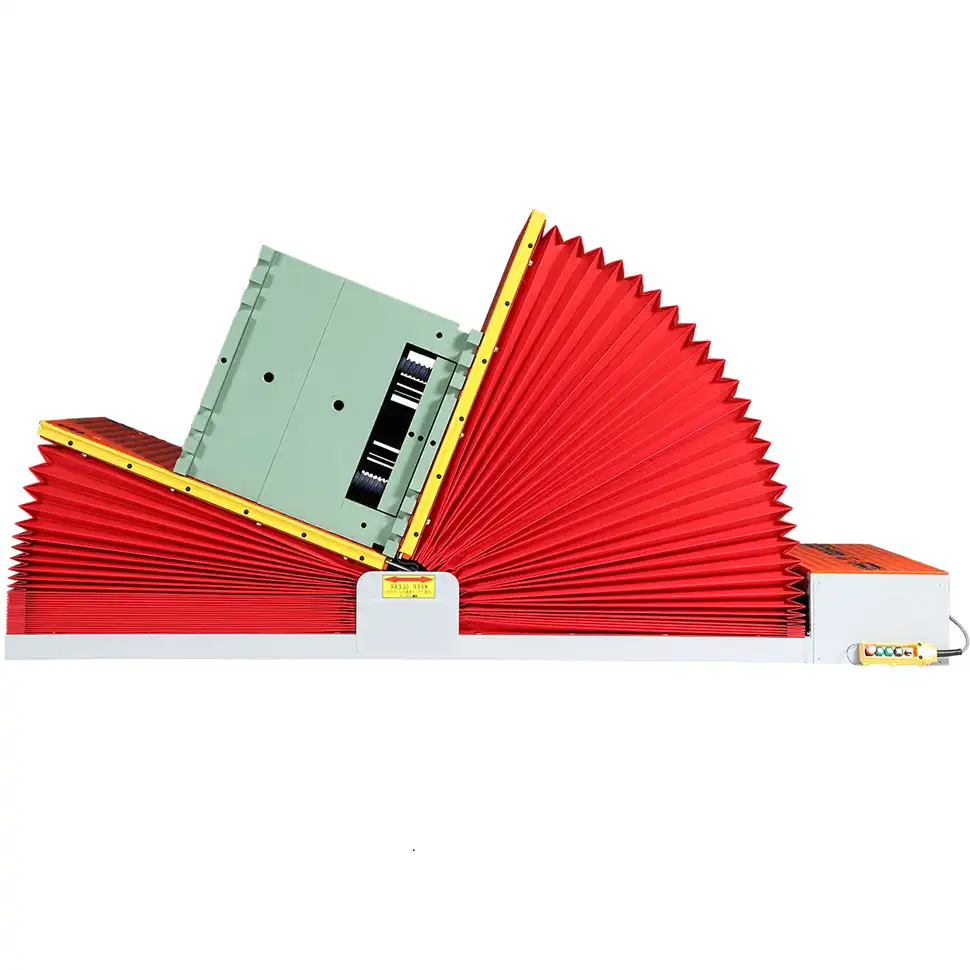

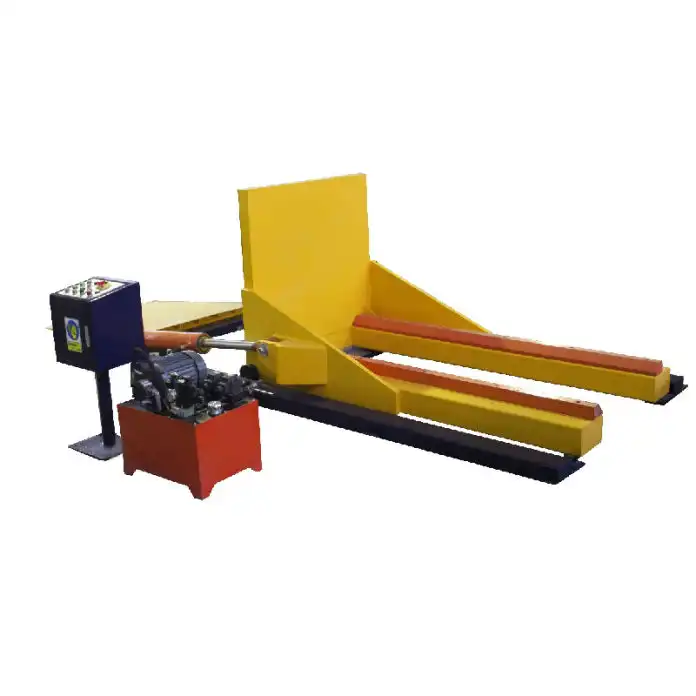

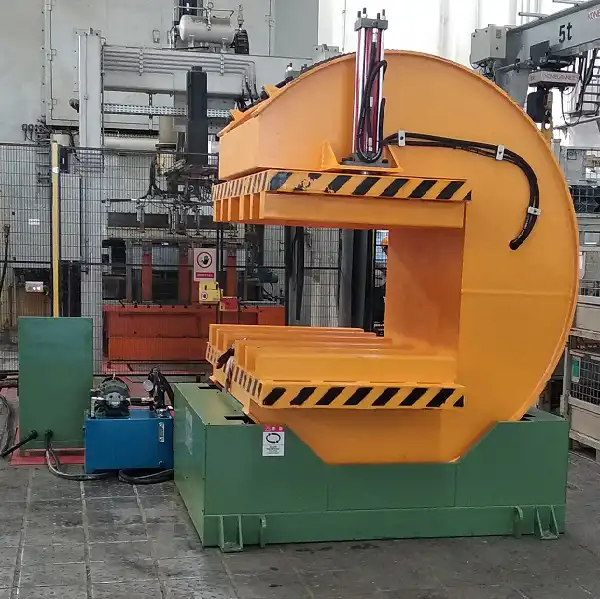

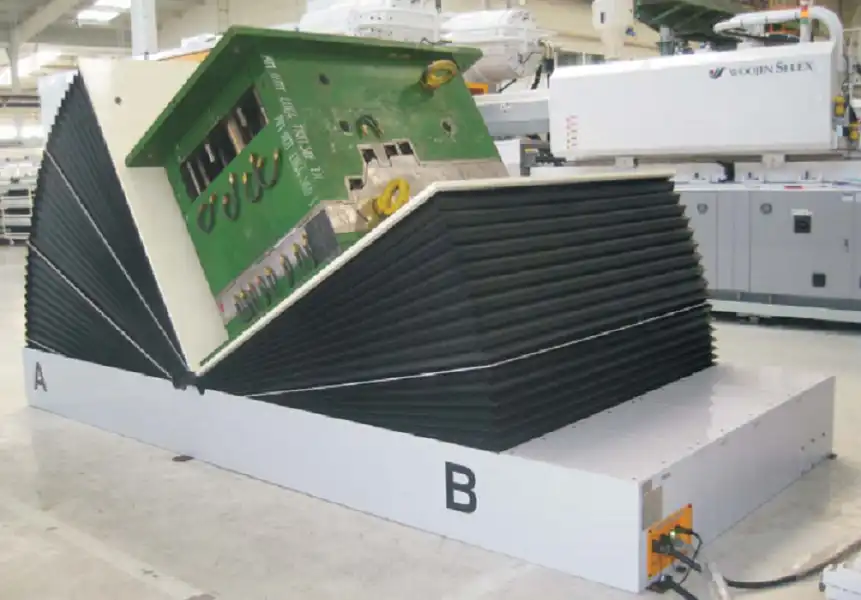

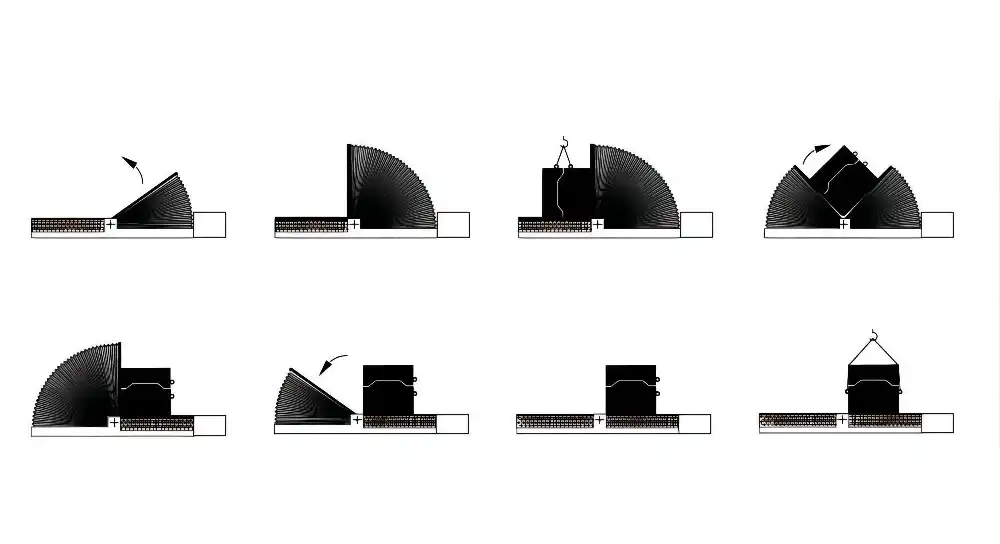

FHOPE offers a range of upenders, including hydraulic, mechanical, and electrical models. Hydraulic upenders use hydraulic cylinders to lift and tilt loads, providing a smooth and controlled motion, while mechanical upenders use mechanical components such as gears and pulleys.

Electrical upenders use electric motors for precise positioning and control. These machines are ideal for a range of applications, including heavy-duty loads in manufacturing and assembly operations.

(1)Benefits and Applications of Upenders

Upenders provide numerous advantages such as enhanced ergonomics, heightened efficiency, and minimized product harm. Their versatility enables them to accommodate an expansive variety of load dimensions and forms.

Frequently utilized in manufacturing, assembly, and warehousing processes, upenders can simplify material management, leading to a significant boost in productivity.

(2)Customization Options

This company offers customization options for their upenders, allowing clients to tailor the equipment to their unique needs.

This includes options for load capacity, speed, power source, and safety features.

3. The Role of Upenders and Tilters in Efficient Logistics Operations

Efficient logistics operations rely on the safe and efficient movement of goods.

Upenders and tilters play a crucial role in streamlining material handling and transport, allowing loads to be positioned and repositioned quickly and easily.

By reducing the time and effort required to move loads, upenders and tilters can help improve productivity and reduce the risk of injury.

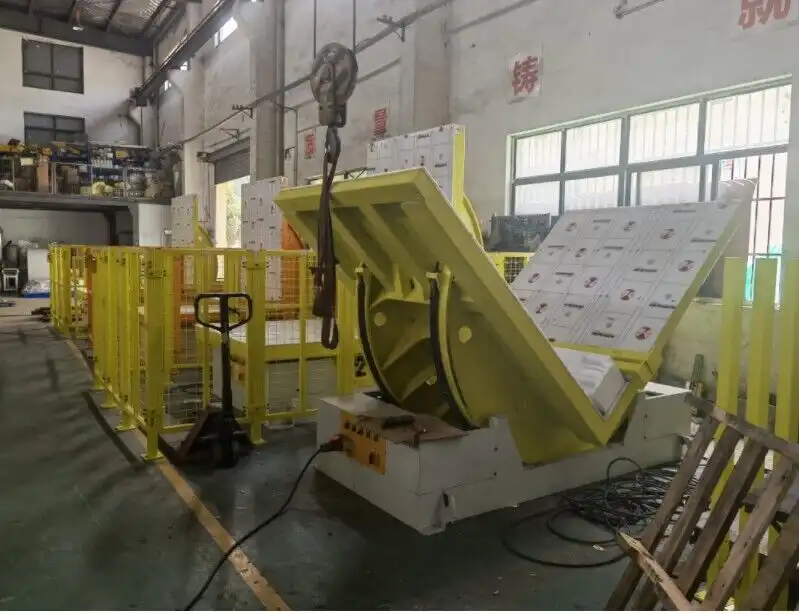

4. Real-World Examples of How These Equipment Streamline Material Handling and Transport

Real-world examples of how upenders and tilters streamline material handling and transport include loading and unloading containers, positioning heavy machinery for assembly, and tilting loads for improved access during inspection and maintenance.

By making these operations more efficient, upenders and tilters can help reduce costs and improve overall productivity.

5. The Benefits of Using Upenders and Tilters in Warehouse Operations

In warehouse operations, upenders and tilters can help improve the efficiency of material handling and reduce the risk of injury.

By improving ergonomics and reducing the need for manual lifting and positioning, upenders and tilters can help reduce the risk of workplace injuries and improve overall productivity.

6. Tips for Optimizing Warehouse Productivity with These Equipment

To optimize warehouse productivity with upenders and tilters, it is important to choose the right equipment for the specific application and load requirements.

Consistent upkeep and assessment can aid in guaranteeing optimal performance of the equipment.

Adequate training for operators is also pivotal in enhancing safety measures and efficiency.

Lastly, collaborating with a seasoned and trustworthy manufacturer is essential to assure the supreme standards of quality and operation.

More information about the mold flipper:https://www.fhopepack.com/Hydraulic/Mold-flipper.html