Mastering Steel Wire Coil Packaging: A Technical Guide to Automatic Wrapping Machines Using Paper

Proper packaging is crucial for protecting valuable steel wire coils during storage and transit. Manual wrapping methods can be time-consuming, inconsistent, and labor-intensive. Automatic wire coil wrapping machines offer a robust solution, enhancing efficiency, ensuring consistent protection, and improving overall operational safety. This guide delves into the technical aspects and operational advantages of a specific type of machine designed for paper wrapping applications.

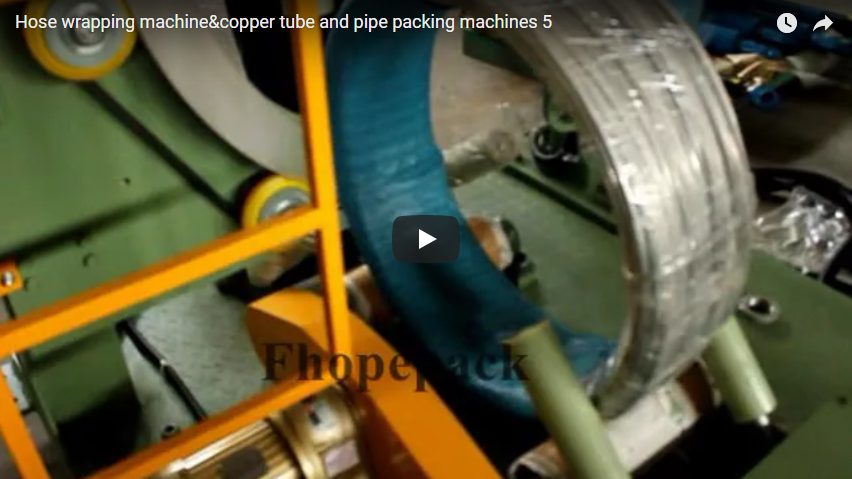

Visualizing the Process: Watch the Machine in Action

1. Core Functionality: Orbital Wrapping Technology

This machine utilizes an orbital wrapping mechanism. The wire coil is positioned, often via conveyor or manual loading, within the wrapping ring's opening. The ring, loaded with the chosen wrapping material (in this case, paper), rotates around the coil while dispensing the material. This orbital action ensures complete, uniform coverage around the coil's circumference, providing a secure and protective layer. It's a fundamental piece of equipment in automated coil wrapping machine lines designed for items like large steel wire coils and wire rod coils.

2. Key Technical Specifications and Their Significance

Understanding the machine's specifications is vital for assessing its suitability for specific operational needs:

- Coil Handling Capacity:

- Supported Coil Widths: 200mm to 800mm. This range indicates versatility, allowing the machine to handle various sizes of wire coils commonly produced in industry.

- Wrapping Materials:

- Compatibility: Designed primarily for paper wrapping but often compatible with PE (Polyethylene), PVC (Polyvinyl Chloride), and specialized materials like VCI (Volatile Corrosion Inhibitor) paper. VCI paper is particularly important as it releases compounds that actively prevent rust and corrosion on the metal surface during shipping and storage. Learn more about VCI technology.

- Performance Metrics:

- Maximum Wrapping Speed: Up to 35 coils per hour. This metric is critical for calculating throughput and ensuring the machine can keep pace with production line output.

- Power Supply: 380V, 50Hz, Three-phase. This is a standard industrial power requirement, important for facility planning.

- Physical Footprint:

- Dimensions (L x W x H): Approximately 3200mm x 2000mm x 2300mm.

- Weight: Approximately 1800kg. These figures are essential for space allocation and floor load considerations during installation planning.

3. Essential Features for Operation and Safety

Modern automatic wire coil wrapping machines incorporate features designed for ease of use, precision, and operator safety:

- Control System (PLC and HMI):

- Operation is typically managed via a Programmable Logic Controller (PLC) coupled with a Human-Machine Interface (HMI), often a user-friendly touchscreen panel. This allows operators to easily set wrapping parameters (e.g., overlap percentage, number of wraps), store different recipes for various coil types, monitor the process in real-time, and access diagnostic information for troubleshooting.

- Adjustable Tension Control:

- This feature allows operators to precisely control the tension of the wrapping material as it's applied. Proper tension is crucial: too loose, and the wrap is ineffective; too tight, and it could potentially damage softer wire types or waste material. Fine-tuning tension ensures optimal protection and material usage.

- Integrated Safety Mechanisms:

- Safety is paramount. These machines are equipped with essential safety features, including:

- Emergency Stop Buttons: Strategically placed for quick shutdown.

- Safety Shielding/Fencing: Physical barriers preventing accidental contact with moving parts.

- Interlock Systems: Sensors that stop machine operation if safety gates or shields are opened during the cycle.

- Safety is paramount. These machines are equipped with essential safety features, including:

4. Maintenance and Efficiency Considerations

- Energy Efficiency: Designed with energy conservation in mind, helping to reduce operational costs and support sustainability goals.

- Ease of Maintenance: Thoughtful design allows for straightforward access to key components for routine checks, lubrication, and troubleshooting, minimizing downtime and ensuring the machine remains in optimal working condition.

Visual Aid: Machine Example

Conclusion

Automatic wire coil packing machines utilizing paper wrapping offer significant advantages over manual methods. They deliver consistent, high-quality packaging, enhance operational throughput, improve safety, and can be adapted to use specific protective materials like VCI paper. Understanding the technical specifications and operational features allows businesses to select and implement the right automated solution to protect their valuable wire products effectively.

For further details on related equipment:

https://www.fhopepack.com/Steel-coil-wrapping-machine/