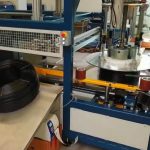

It is off-line pvc pipe bundle forming and strapping machine testing video which is for off -line pipe feeding and counting.

The machine straps by stretch film with 3 stations.

So the 3 place can be wrapped in one time.

Speed: 30000pic per day.

Pipe length:3/4/6m

Controal:Automation

An off-line PVC pipe bundle forming and strapping machine is a type of machine designed to automatically form and strap PVC pipe bundles for efficient transportation and storage. The machine is typically designed to work with PVC pipes of varying lengths and can be customized to accommodate specific packaging requirements.

The forming and strapping process is typically initiated by feeding the PVC pipes into the machine, which then automatically forms them into a bundle and applies stretch film strapping to secure the bundle for transportation or storage. The machine has three stations, allowing for three places to be wrapped in one time, which can help increase efficiency and productivity.

Some common features of off-line PVC pipe bundle forming and strapping machines include:

- Adjustable pipe length: Many machines allow you to adjust the pipe length to suit the specific requirements of your packaging needs.

- Automatic forming and strapping: This feature allows the machine to automatically form the PVC pipes into a bundle and apply stretch film strapping to secure the bundle for transportation or storage.

- Multiple stations: The machine has multiple stations for wrapping, allowing for multiple places to be wrapped in one time, which can help increase efficiency and productivity.

- High-speed production: These machines are designed to handle high production volumes, with the ability to form and strap up to 30,000 PVC pipes per day.

- Automation control: The machine is equipped with automation controls, allowing for a high level of precision and control over the forming and strapping process.

Overall, off-line PVC pipe bundle forming and strapping machines can help increase efficiency and productivity in manufacturing and production facilities by automating the forming and strapping process and reducing the need for manual labor. They are available in a range of sizes and configurations to suit different pipe lengths and packaging requirements, and can be customized with additional features and options to meet specific needs.