Optimizing Load Security: A Technical Guide to Automatic PET Strapping Machines

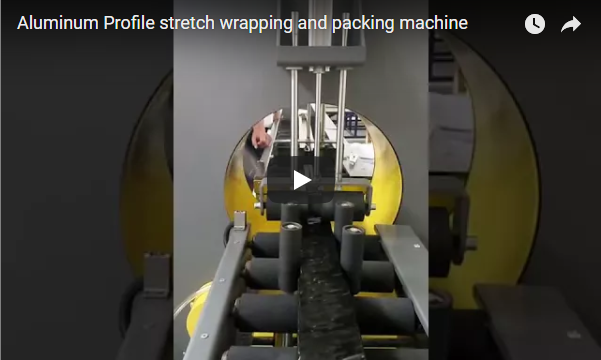

Video demonstrating the operation of an automatic strapping machine.

1. Introduction to PET Strapping Technology

Automatic PET (Polyethylene Terephthalate) strapping machines are essential equipment in modern packaging and logistics operations. Designed specifically for securing loads with high-strength PET straps, these machines play a crucial role in stabilizing heavy, bulky, or irregularly shaped items for safe transit and storage. PET strapping is favored for its high tensile strength, excellent tension retention properties, and resistance to environmental factors like UV rays and moisture, making it a reliable alternative to traditional steel strapping in many applications. Automation in this process significantly enhances operational efficiency, consistency, and safety compared to manual or semi-automatic methods.

2. Core Operating Principles and Components

An automatic PET strapping machine streamlines the packaging process through a coordinated sequence of actions:

- Strap Feeding: The machine automatically feeds the PET strap from a dispenser coil through an arch or frame positioned around the package.

- Tensioning: A tensioning system applies a pre-set amount of force to the strap, pulling it tight around the load. Precise tension control is critical to ensure load stability without damaging the product. Tensioning mechanisms can be electrically or pneumatically driven.

- Sealing: Once optimal tension is achieved, the strap ends are joined. The most common method in PET strapping machines is friction weld sealing. This technique uses high-speed vibration or friction between the overlapping strap ends to generate heat, melting the PET material and creating a strong, reliable bond without the need for metal seals.

- Cutting: After sealing, an integrated cutting unit cleanly trims the excess strap from the coil.

Key components typically include a robust frame, strap dispenser (coil holder), strap arch (guide frame), tensioning head, sealing unit (friction welder), cutting mechanism, and a control system (often PLC-based) allowing operators to set parameters like tension level and cycle timing.

3. Representative Technical Specifications

Understanding the typical parameters of an automatic PET strapping machine helps in assessing its capabilities for specific industrial needs.

Note: The specifications listed below are representative and may vary based on the specific model, manufacturer, and configuration. Always refer to the manufacturer's documentation for precise equipment details.

- Machine Type: Fully Automatic PET Strapping System

- Strap Compatibility: Polyethylene Terephthalate (PET) straps

- Strap Width Range: Typically 12mm to 19mm (configurable based on model)

- Strap Thickness Range: 0.6mm to 1.2mm (depends on tension requirements and model design)

- Strap Roll Core Inner Diameter: Standard options like 200mm or 406mm

- Tension Strength: Adjustable, commonly up to 4500N (Newton) or higher for heavy-duty applications

- Sealing Method: Friction weld seal (provides high joint efficiency)

- Strapping Cycle Speed: Varies by model and package size, often ranges from 10 to 20 straps per minute

- Control System: PLC (Programmable Logic Controller) with HMI (Human-Machine Interface) touch screen for parameter setting and diagnostics

- Operation Mode: Fully automatic integration with conveyor lines, or manually initiated cycles

- Power Requirements: Commonly 230V/400V, 50/60Hz, 3-phase (specifics vary)

- Machine Dimensions (Typical): Length: ~1400-2000mm; Width: ~600-800mm; Height: ~1500-2200mm (highly dependent on arch size)

- Machine Weight (Typical): Approximately 200kg - 500kg

- Safety Features: Emergency stop buttons, safety interlocks on access panels, tension overload protection

4. Key Industrial Applications and Benefits

Automatic PET strapping machines provide significant advantages across various sectors:

-

Transportation and Logistics: Enhancing Load Stability

In the high-volume world of logistics, ensuring palletized goods or large crates remain secure during handling and shipping is paramount. Automatic PET strapping machines apply consistent, high tension (e.g., up to 4500N) to firmly unitize loads, significantly reducing the risk of product shifting, damage, and costly returns. The automation speeds up the end-of-line packaging process, improving throughput in distribution centers and meeting carrier requirements for secure shipments. -

Manufacturing Industries: Streamlining Production Output

Manufacturers dealing with bundled products like lumber, bricks, tiles, corrugated sheets, metal extrusions, or appliances rely on effective strapping for maintaining bundle integrity. Integrating an automatic PET strapper into the production line ensures that products are securely bundled quickly and reliably. This supports continuous manufacturing workflows, reduces manual labor dependency, and prepares goods for storage or immediate dispatch more efficiently. -

Warehousing and Storage: Improving Safety and Space Utilization

In warehousing, stable storage is crucial for safety and maximizing space. PET strapping machines help consolidate stored goods, preventing stacks from becoming unstable or collapsing. Properly strapped bundles are easier and safer to handle with forklifts or other equipment. The ability to adapt strapping patterns and tensions for different load types makes these machines versatile tools for maintaining organized and secure inventory in diverse warehousing environments.

Steel tube bundle strapping machine 5. Practical Considerations and Experience Sharing

Optimizing the performance and longevity of an automatic PET strapping machine involves several practical aspects:

- Strap Quality: Using high-quality PET strap that meets the machine's specifications (width, thickness, elongation properties) is crucial. Inconsistent strap quality can lead to feeding issues, poor seal integrity, or component wear.

- Regular Maintenance: Preventive maintenance schedules should be followed, focusing on cleaning the sealing head and cutter, inspecting wear parts in the tensioning mechanism, and ensuring proper strap alignment. This minimizes downtime and ensures consistent performance.

- Operator Training: Proper training on machine operation, safety procedures, parameter adjustments (like tension settings), and basic troubleshooting is vital for efficient and safe use.

- Integration: When integrating into automated lines, ensure proper communication protocols (e.g., signals for start/stop, cycle complete) are established between the strapper and upstream/downstream conveyor systems.

- Environmental Impact: PET strapping is often preferred for its recyclability compared to other materials. Implementing strap waste collection and recycling programs can enhance sustainability efforts. Learn more about PET plastic properties and recycling.

6. Conclusion

Automatic PET strapping machines offer a robust and efficient solution for securing a wide range of industrial loads. By providing consistent high tension and reliable friction weld seals, they enhance product protection, streamline packaging operations, and contribute to safer handling and transportation across logistics, manufacturing, and warehousing sectors. Understanding their technical specifications, operational principles, and practical considerations allows businesses to effectively leverage this technology for improved load security and operational efficiency.

For further examples of related automation in packaging:

Automatic Strapping Machine Solutions