Introduction:

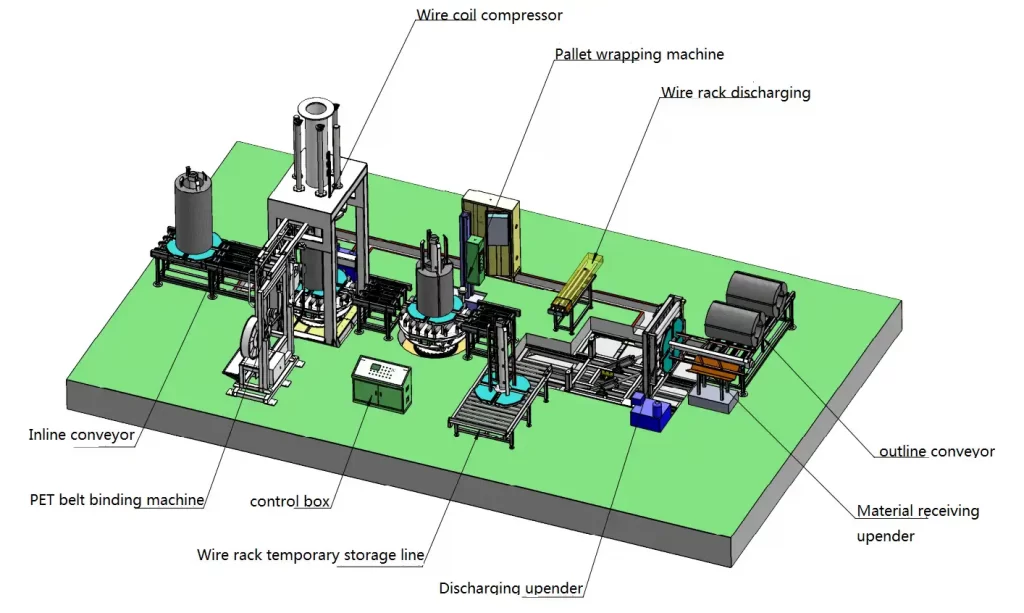

The automatic steel wire compacting and strapping line is a revolutionary piece of machinery in the wire industry that has greatly improved the process of compacting and strapping steel wire coils.

In this article, we will delve into the 10 most important frequently asked questions about the automatic steel wire compacting and strapping line, providing detailed information to help you better understand this machinery.

1. What is the height range of the wire coil before compacting?

This is the necessary information that the data for compacter height, moving range…

The wire coil’s height before compaction is determined by its weight. A coil weighing 500 kg may reach a height of up to 600 mm, whereas a 1000 kg coil can reach a height of up to 1220 mm.

It’s crucial that the automatic steel wire compacting and strapping line can accommodate both of these heights.

2. What is the size of the compacted wire coil?

The wire height after compacting

After compacting, the wire coil size will be between xxx mm and xxx mm for different coil OD sizes.

The packing line need to be designed for compacting, packing, basket take off… per easier to handle and transport.

3. How many coils can be processed per hour?

The processing capacity of an automatic steel wire compacting and strapping line is an important factor to consider when choosing a machine.

In this case, the system can process up to 10 coils per hour, which is equivalent to approximately 240 coils in 24 hours.

The speed of the packing line is approximately 4-5 minutes per coil, so processing 10 coils per hour is no problem.

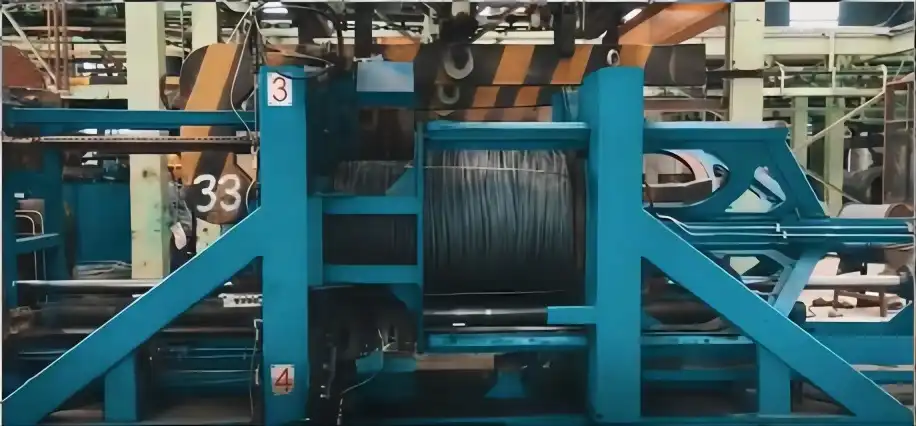

4. Do I need a special wire rack for strapping?

Yes, a special wire rack is required for the strapping process. The wire rack allows the strapping machine to thread through the center of the coil while keeping the wire rack and steel wire separate.

The wire rack can be provided by the manufacturer or produced in-house.

We can provide wire rack drawings or produce the wire rack for our customers.

5. What is the maximum wire diameter that can be processed?

The automatic steel wire compacting and strapping line can process wire diameters up to 5.0 mm, which is larger than some quotes suggest.

It is important to ensure that the machine can handle the wire diameter required for the specific application.

6. Is the machine fully automatic?

Yes, the automatic steel wire compacting and strapping line operates automatically, requiring minimal operator intervention.

Once the coils are placed on the line, the system will automatically compact and strap them, greatly improving the efficiency of the production process.

7. What type of strapping is used?

The strapping used in the automatic steel wire compacting and strapping line is of high quality to ensure that the coils are securely strapped.

The strapping material can be chosen based on the specific needs and requirements of the application.

8. How much space does the machine require?

Automatic steel wire compacting and strapping lines require a significant amount of space to operate.

The wire coil’s height before compaction is determined by its weight. A coil weighing 500 kg may reach a height of up to 600 mm, whereas a 1000 kg coil can reach a height of up to 1220 mm.

It’s crucial that the automatic steel wire compacting and strapping line can accommodate both of these heights.

9. What kind of maintenance is required?

To ensure optimal performance and longevity, regular maintenance is required for the automatic steel wire compacting and strapping line.

This involves cleaning, lubricating, and examining all moving components.

Adhering to the manufacturer’s maintenance instructions is critical to guaranteeing proper machine functionality.

10. What safety features are included in the machine?

Automatic steel wire compacting and strapping lines are equipped with various safety features to protect operators and prevent accidents.

These features may include emergency stop buttons, safety guards, and warning signals.

Prior to operating the machine, it’s crucial to verify that all safety features are present and operational.

More:

In addition to the above FAQs, there are several other factors to consider when choosing an automatic steel wire compacting and strapping line. These include the machine’s speed, ease of use, and customization options.

1. Speed:

The speed of the automatic steel wire compacting and strapping line is an important consideration for wire manufacturers.

Increased machine speed directly translates to a higher hourly coil processing rate, which leads to improved productivity and profitability.

2. Ease of Use:

A user-friendly machine interface and streamlined maintenance procedures are vital considerations for ease of use.

This can help mitigate operational mistakes and minimize maintenance-related downtime.

3. Options:

Customizability is a crucial factor to consider when selecting the machine, as it should be capable of meeting the unique needs and requirements of the application.

This may entail the capacity to handle varying wire diameters, modify the compacted coil size, or utilize diverse strapping options.