http://www.fhopepack.com/Hose-coiling-and-strapping-machine.html for automatic pipe and hose coil making, strapping and eye through packaging

automatic pipe hose coiler and strapping machine

More information: info@fhopepack.com

Increase your productivity and reduce labor costs with an automatic pipe hose coiler and strapping machine. Learn about the benefits of this industrial equipment and how it can streamline your operations.

Are you looking for a way to streamline your processes and increase productivity in your industrial operations? Look no further than an automatic pipe hose coiler and strapping machine.

What is an Automatic Pipe Hose Coiler and Strapping Machine?

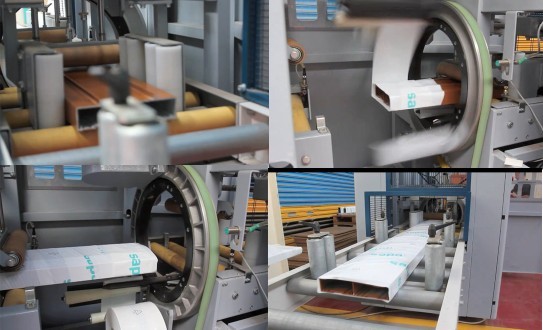

An automatic pipe hose coiler and strapping machine is a type of industrial equipment used to automatically coil and strap pipes or hoses for storage or transportation. The machine typically consists of a coiling unit that winds the pipes or hoses into a tight and uniform coil, and a strapping unit that applies a band or strap around the coil to hold it securely in place.

Benefits of an Automatic Pipe Hose Coiler and Strapping Machine

Using an automatic pipe hose coiler and strapping machine can provide numerous benefits to your business. Firstly, it can help to increase efficiency and productivity by automating the coiling and strapping process, reducing the need for manual labor and increasing output. This can help you to save valuable time and resources, and ultimately increase profitability.

Secondly, an automatic pipe hose coiler and strapping machine can help to improve the quality and consistency of your coiled pipes or hoses. By using a machine to coil and strap your pipes or hoses, you can ensure that they are tightly and uniformly coiled, reducing the risk of damage or breakage during storage or transportation. This can lead to fewer product defects and lower costs.

Thirdly, using an automatic pipe hose coiler and strapping machine can help to reduce the risk of injury or strain on workers by automating heavy or repetitive tasks. This can improve safety in the workplace and lead to a better work environment for your employees.

———————————————————————

- How to operating Pipe packaging line Film Delivery System Power Roller-Stretch Additionally …

- upender Manufacture drawings, manufacture supervision report and record, inspection and test report before delivery, running test report and unpack report, etc. Other standards approbated by both Seller and Buyer.4.3 Content of inspection and acceptance

- Top supplier for Cable wrapping machine production line and sharing products information for automatic packaging. The automatic packing line will be designed per different ..

- the technical data of Tyre wrapping machine offering individual content articles to a conveyor program;

- the technical data of Pipe coil wrapping machine The period of guarantee has a term of 12 months since the confirmation date of eligibility of inspection and acceptance. It will be to Seller’s care to maintain the equipment free of charge during the guarantee period. But the guarantee term excludes: Equipment damage caused by force majeure Any changes on design without Seller’s approval Equipment damage not to Seller’s responsibility Roll Diameter

- the feacture of the PPR/PVC Pipe bundling machine To test and confirm the integrality of functions and working procedures in load running situation. To test and confirm the system reliability in load running situation. To exam and confirm that the equipment can realize values guaranteed in Inspection and Exam Stipulations. As destructive as earthquakes are, there are ways to minimize preventing some of the damage they are able to cause. As an example, better engineering, design, and building codes have dramatically reduced the potential risk of damage from earthquakes. Likewise, better stretch wrapping is able to reduce risk of damage to your pallets from mini earthquakes during shipping.

- How to operating Coil packaging machine The machine, equipped with the appropriate device, is self-cleaning and it is very low maintenance because of the simple construction. Vacuum bagging and film packaging and gas flush options result in the Bingo Bagger well suited for food service, Don??¥t be victimized by mini earthquakes. Minimize the risk of your loads being damaged from your outcomes of vibration enroute to your customers. It’s not that hard and the benefits are enormous. …

- the feacture of the tilter and upender an article supply for supplying individual articles;the packaging subsystem with regard to packaging person articles in to packs; Film Delivery System Power Roller-Stretch Additionally … …